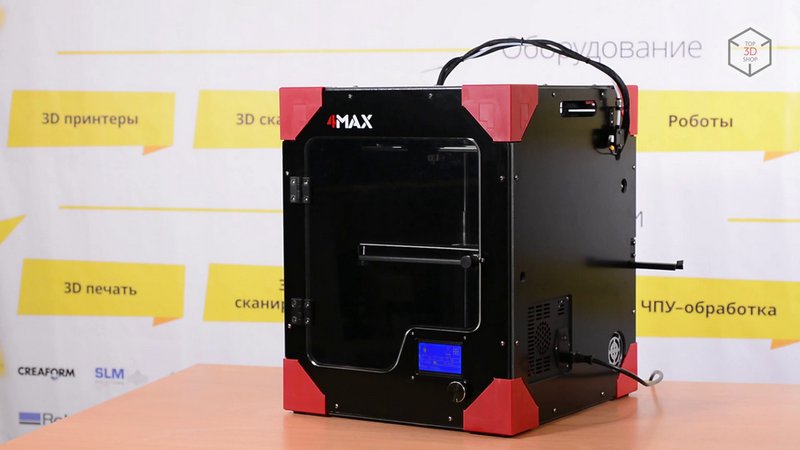

Hi, everyone! In this review, we will tell you about the Anycubic 4Max FDM 3D Printer.

The 4Max FDM 3D Printer was announced by the Chinese company Anycubic in early 2018. The device came to market in spring the same year. At the end of the review, we also will tell you about the new version of the model — Anycubic 4Max Pro and its distinctive features.

Characteristics:

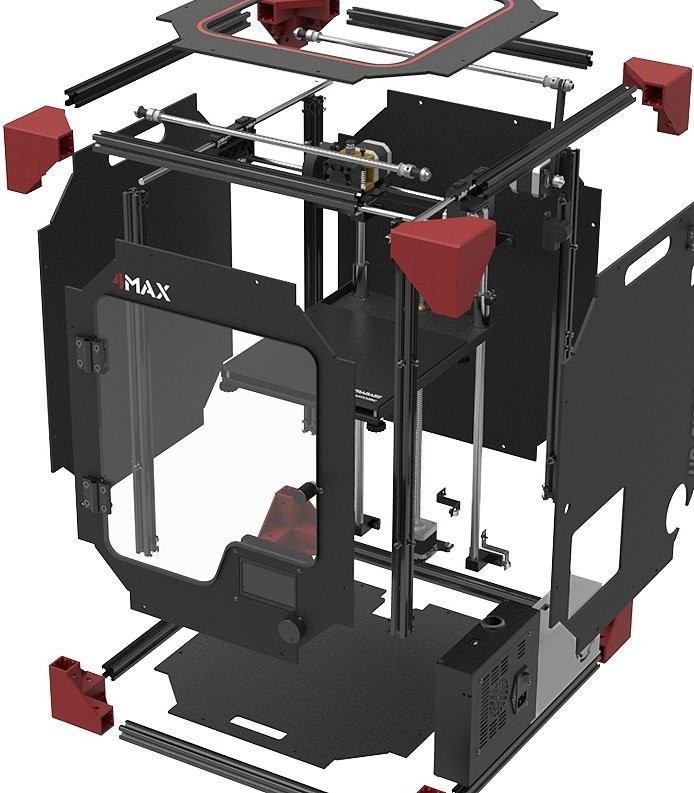

This large and powerful FDM printer with a closed build chamber is supplied unassembled.

This desktop 3D printer is not as easy to build as the Anycubic i3 Mega, but all in all, it creates no problem.

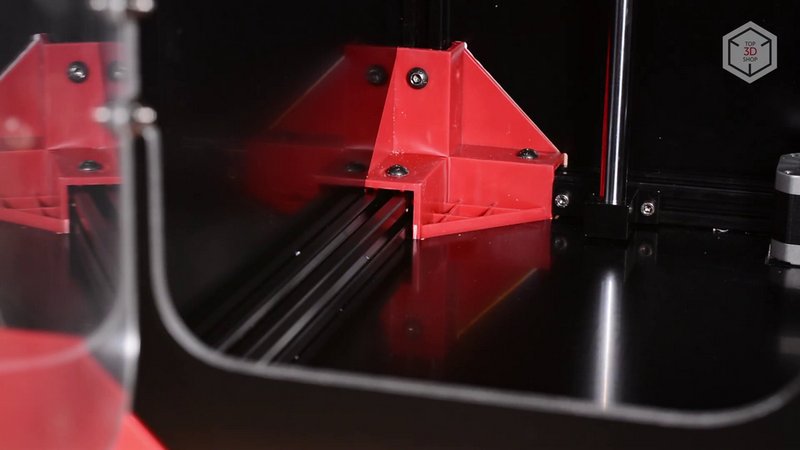

The frame is constructed from extruded aluminum. Its elements are connected by large plastic joint angles.

All the sides of the device are covered with composite panels, except for the upper cover.

A closed build chamber is where the 4Max stands out from its medium-price competitors. It makes it easier to print with notoriously difficult materials, such as ABS and nylon. These filaments require not only a heated bed, but also good temperature management within the printer itself.

Additionally, the enclosed build room improves the quality of the upper layers of larger prints.

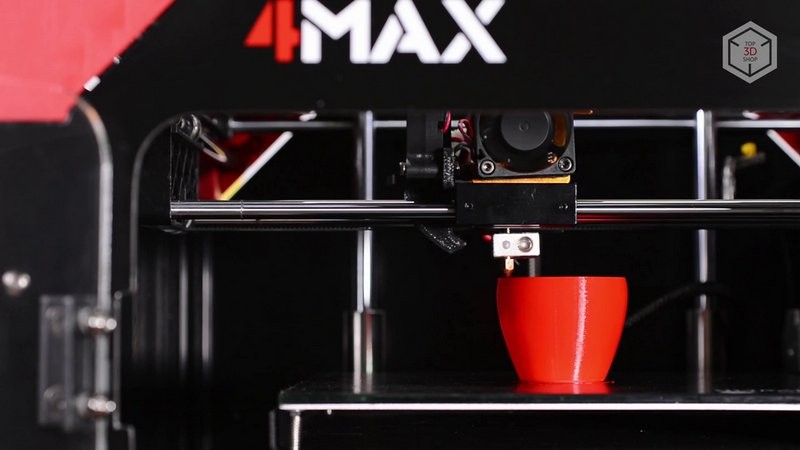

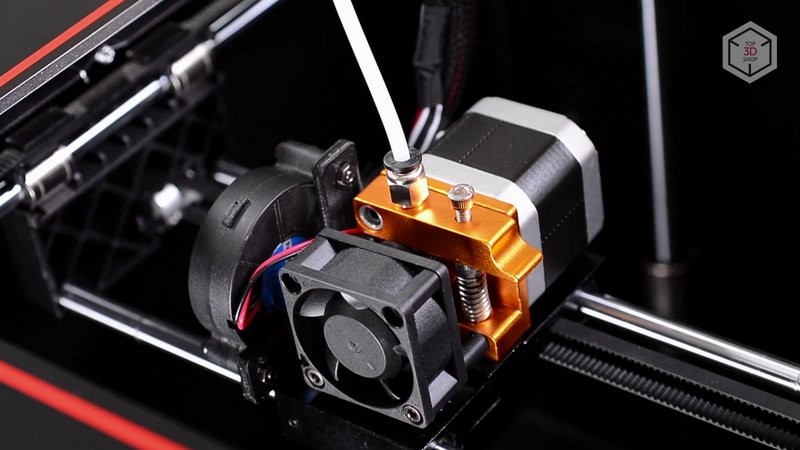

Anycubic 4Max is equipped with a direct drive extruder. According to the device’s kinematic scheme, there is a separate motor for each axis.

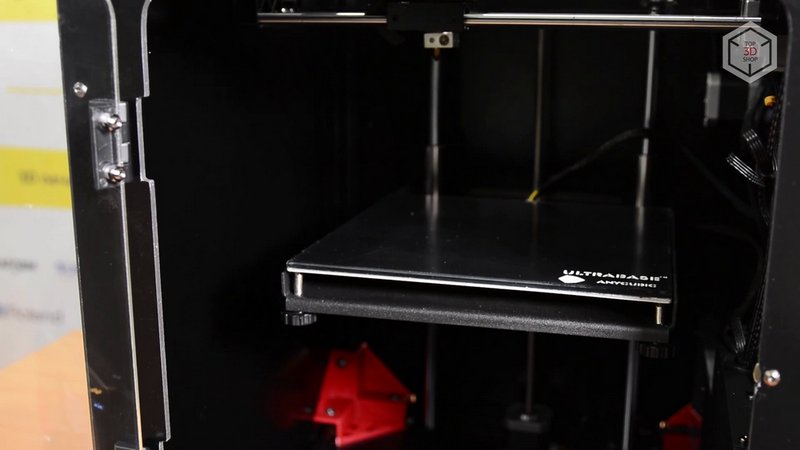

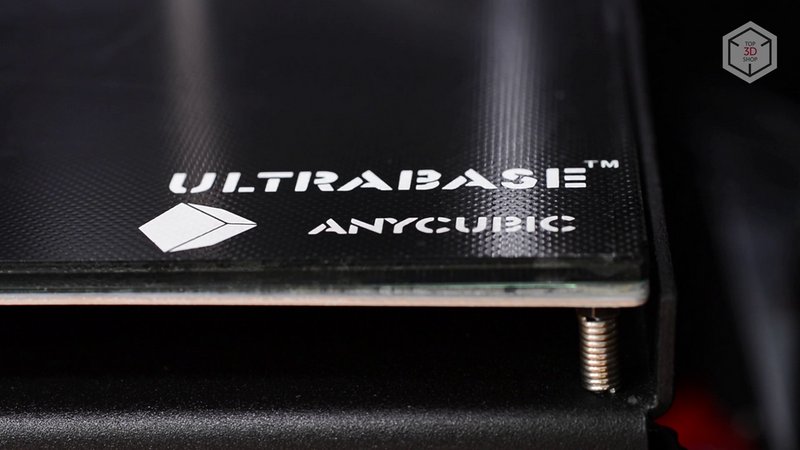

The printer has the Anycubic Ultrabase heated bed — the company’s proprietary solution.

Its surface is covered by a layer of special porous coating to provide excellent adhesion and prevent printed models from moving. After the print is finished, the bed cools off, the micropores’ thermal expansion is followed by shrinkage, and only a little effort is needed to lift 3D printed objects off the surface.

The print bed leveling is performed manually, by turning the screws located under the platform.

The Anycubic 4Max 3D printer kit includes the LCD-display and rotary knob.

You can load a model via an SD card or connect the printer to a computer via USB and print directly from there.

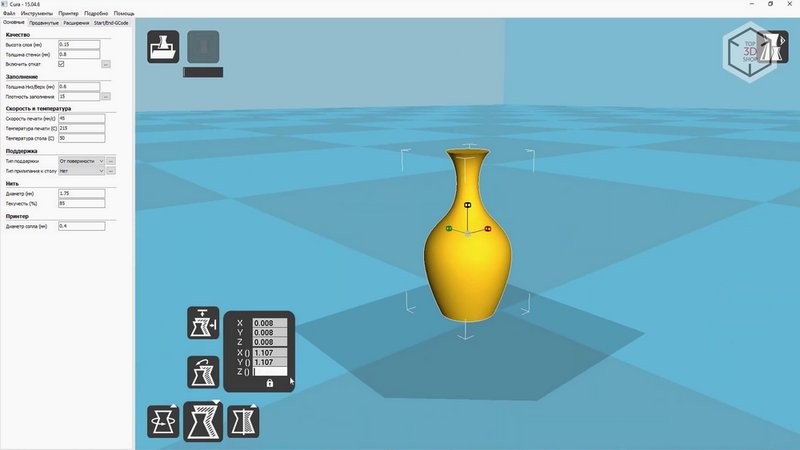

When it comes to 3D slicing, the manufacturer offers a dedicated version of Cura on its SD card.

The filament outage sensor reduces the risk of poor print quality. No more printing in the air due to the filament outage — with the dedicated mechanical sensor, the printer senses if spool runs out and stops automatically.

The printer itself is capable of producing prints as big as 210 x 210 x 300 mm. Anycubic 4Max is suitable both for printing 3D prototypes and creating large-scale models.

One more example:

It is no secret that the creators of 4Max were clearly inspired by the Zortrax M200, which is a big hit across Europe at a much higher price. The engineers of Anycubic managed to cut the printer’s cost without sacrificing quality.

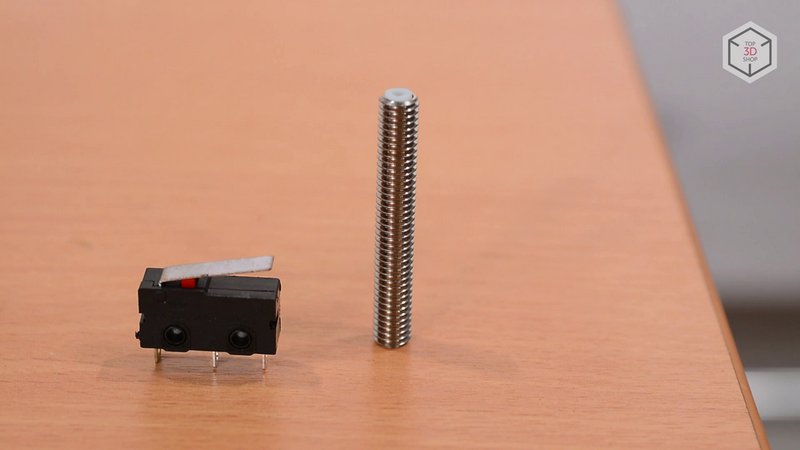

The printer comes with a tool kit, a filament spool, a card-reader, an SD-card, and a repair kit including custom endstop switches and a thermal barrier.

A fully enclosed build space, interesting comfort features, and a very competitive price are the key benefits of this model.

Now there is an improved version of the original 4Max — Anycubic 4Max Pro:

Characteristics:

Major Distinctive Features of the Pro Version:

The end choice on what 3D printer to select is up to you. And we are always ready to consult you and help you choose the best model for your personal preferences and requirements.

Update your browser to view this website correctly. Update my browser now

Write a comment