Hi everyone! This is Top 3D Blog with another article covering a new addition to the world of 3D technologies. We will talk about the EPAX X10 — a mid-sized professional LCD/SLA 3D printer by the USA-based manufacturer EPAX 3D. Offering an incredible level of accuracy, stability and featuring a reliable design, the X10 is a great choice for experienced users in the need of consistently high-quality results.

In this article, we are going to review the main specs and features of the EPAX X10, highlight the pros and cons of the machine, as well as provide pictures of print results.

Source: epax3d.com

EPAX 3D is a 3D printer manufacturer with headquarters located in the Research Triangle area in North Carolina, USA, and with a factory in China. The company focuses on producing resin printers, mainly using the MSLA and LCD technologies. Their devices are often modular and upgradeable.

The most successful 3D printer produced by EPAX 3D is the EPAX X1. The X10 is essentially a significantly larger version of the device.

The company also sells resins for 3D printing and other consumables.

Source: epax3d.com

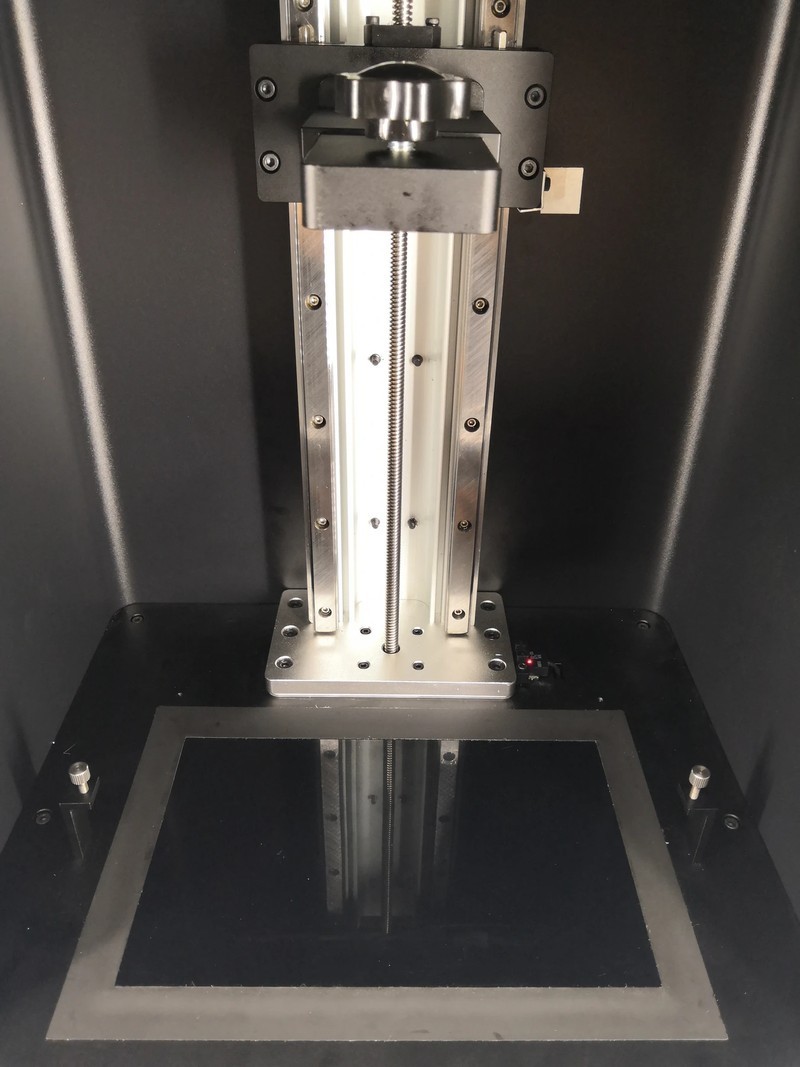

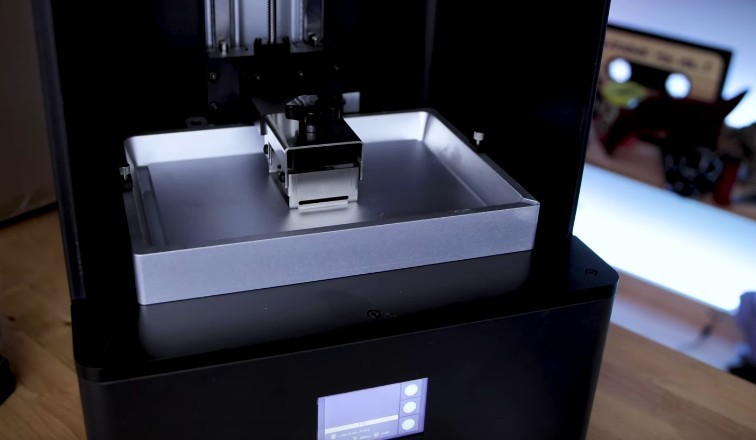

The EPAX X10 is a professional LCD-based UV resin 3D printer. It features a mid-sized build volume of 216 x 135 x 250 mm. It’s a sturdy machine designed with reliability in mind: factory-calibrated parts, upgraded Z-axis drive with linear rails (this configuration is built to eliminate the Z-wobble as successfully as possible) and an all-metal balanced chassis makes the whole build quite robust.

Source: epax3d.com

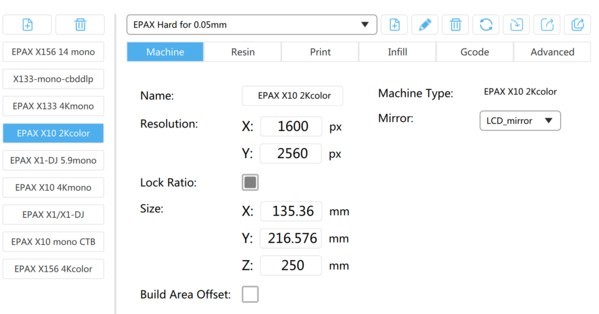

10.1-inch 2K (2560 x 1600) LCD masking is integral in producing highly accurate results. The upgrade kit to 4K resolution is also available and sold separately. The machine is controlled with a built-in 3.5-inch color touchscreen and the connectivity options include Ethernet and USB.

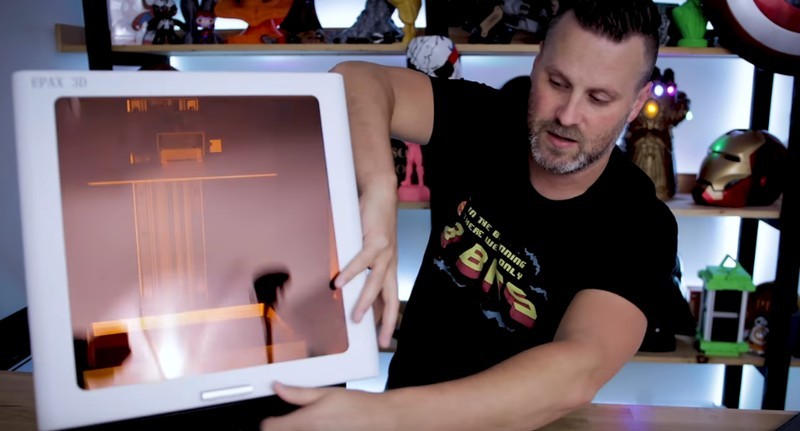

The machine features an all-metal well-balanced chassis and weighs around 19kg. It’s available in dark colors with a yellow see-through door. The latter features an interesting design solution: it opens upwards.

Source: youtube.com

The USB port is located on the side of the device which is very convenient since it makes it much more accessible than placing it on the back of the machine.

Source: youtube.com

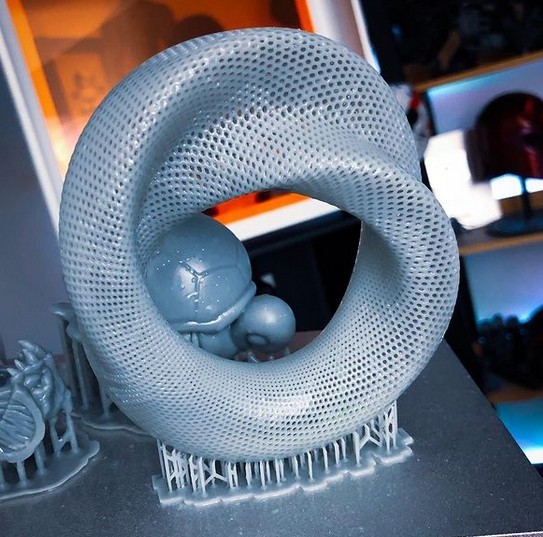

The EPAX X10 can be successfully used in a variety of applications. It is perfect for the production of tabletop miniatures, jewels, dental models, prototypes, and art designs. It would be a fine choice for professional applications and experienced makers.

The image below shows a very complex model (a distorted torus) printed on the EPAX X10. The result is impressively detailed and has a smooth surface finish.

Source: instagram.com

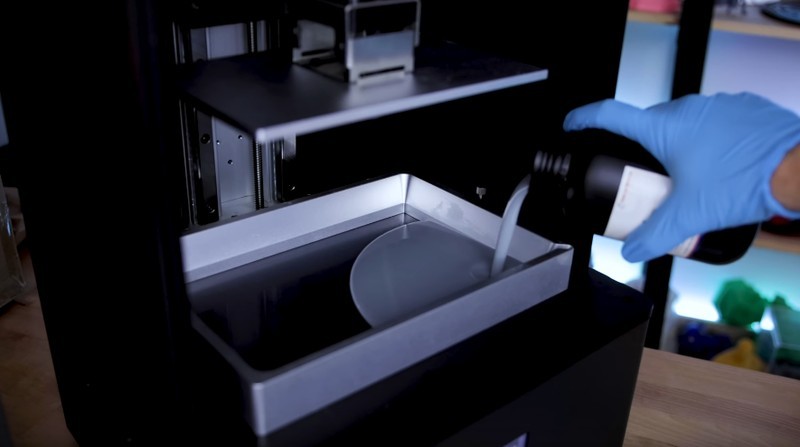

The machine is compatible with all 405 nm wavelength 3D printing resins. EPAX also sells its own proprietary materials designed for a wide variety of purposes. There are heat-resistant, washable, and castable resins available by the manufacturer, as well as many others.

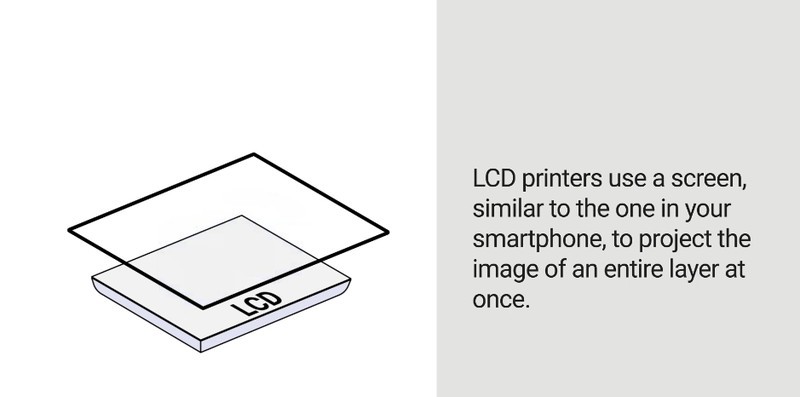

The EPAX X10 utilizes a pretty standard LCD screen. EPAX chose to use a reliable tried and true solution instead of using something revolutionary. The LCD 3D printing technology is quite common and the way it works is rather straightforward: an array of LEDs flash the UV lights in a parallel fashion through an LCD screen. It’s a fast solution and since the lights are tightly focused, there’s not much room for pixel distortion.

Source: youtube.com

There are drawbacks, of course: the LED lights are slightly damaged each time during the process and have a short lifespan. So LCD masking panels are treated as consumables by the manufacturers.

The resolution of the screen used in the EPAX X10 is relatively high: it’s 2K (2560 x 1600 pixels) and the size of the screen is 10.1 inches. It allows for a good level of pixel density and plays a huge role in producing accurate results. The 4K version of the EPAX X10 not only does feature higher resolution but also a slightly smaller (at 8.9 inches) masking screen. The screens were designed to provide uniform and even light distribution across the whole print area.

The EPAX X10 is controlled using a built-in 3.5-inch color TFT touchscreen. The interface is clean and minimalistic, so operating the device is a rather intuitive process. The connectivity options include USB and Ethernet, so the machine can be controlled using a PC.

Source: youtube.com

The EPAX X10 comes neatly packaged in a large box. Removing protective foam that’s placed both inside and around the machine is the only thing that needs to be done since the device comes fully assembled.

Source: instagram.com

Source: epax3d.com

The contents include:

For some items, package content may change. In case of any questions, please get in touch.

The EPAX X10 comes fully assembled and factory-calibrated. After the initial unboxing process, the only thing left to do is to connect the power cord and turn on the machine.

Source: youtube.com

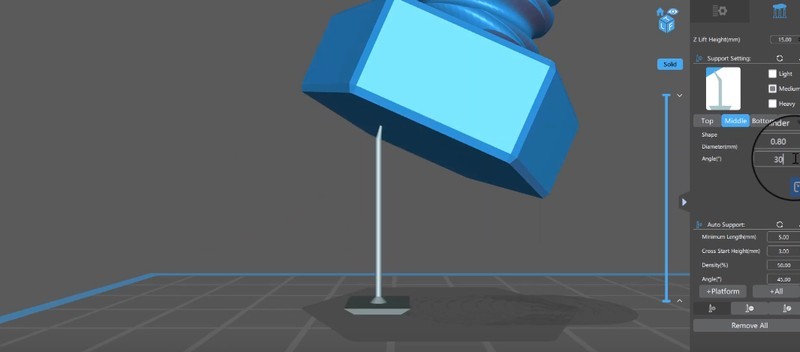

ChiTuBox — the most common slicing software for resin 3D printers — is recommended by the manufacturer to be used with the EPAX X10.

Source: youtube.com

It’s a powerful program that offers an intuitive yet functional interface and does a good job preparing the models.

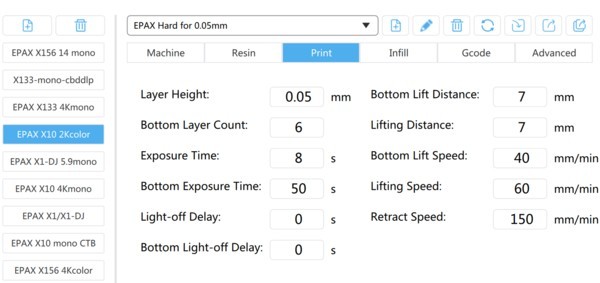

The pictures below show the recommended settings for the EPAX X10 (2K 10.1-inch version). The manufacturer advises the users to make sure that they selected "CBDDLP" file format when slicing and saving files.

Source: epax3d.com

Look at this figurine. The level of detail and surface finish is astounding.

Source: instagram.com

And from another angle:

Source: instagram.com

And these dragons showcase how good the surface finish is.

Source: instagram.com

Pros

Cons

The EPAX X10 is a professional LCD resin 3D printer with a mid-sized build volume, user-friendly operation, and impressive accuracy. Designed with reliability in mind, the machine doesn’t offer much in terms of high-tech latest and greatest solutions but is a great device with the robust build, low level of the Z-wobble, and some upgradeability options.

The 85 microns of XY-resolution and 10 microns of the resolution over the Z-axis make high levels of accuracy possible, so the resulting prints are impressively detailed and feature smooth surface finishes. The device will be a great choice for professionals and experienced enthusiasts in a decent number of fields: from the production of tabletop miniatures and artworks to functional prototypes and dental models. The machine can also be used in the jewelry industry.

Update your browser to view this website correctly. Update my browser now

Write a comment