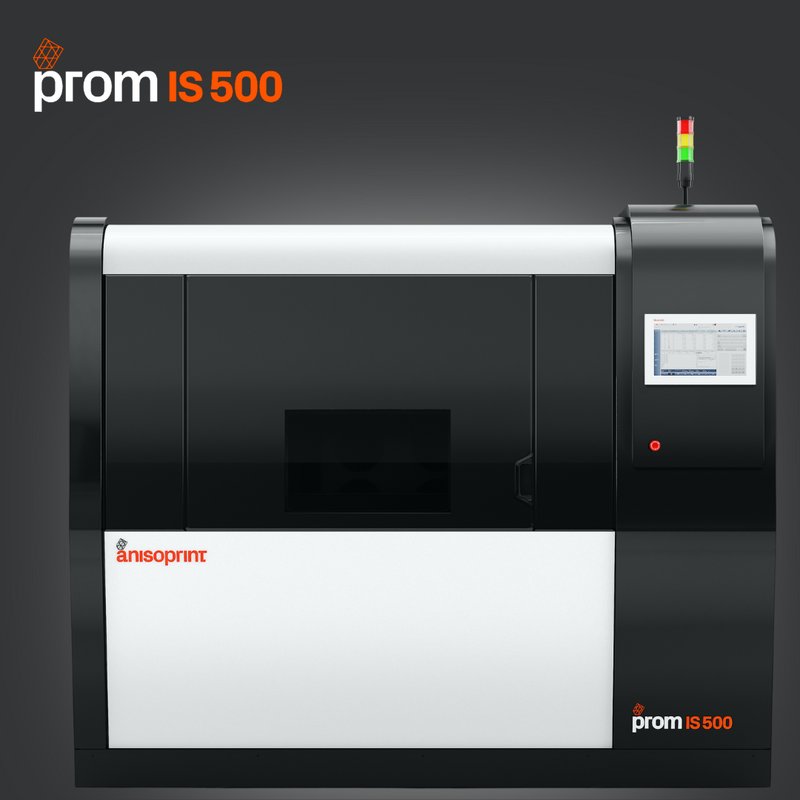

The ProM IS 500 is an industrial machine that combines the Anisoprint’s proprietary Composite Fiber Co-Extrusion technology with basic Fused Deposition Modelling. The printer offers a simple, fast, and cost-effective way to produce high-strength parts using continuous carbon fiber reinforced composites.

Let’s take a brief look at the machine’s main characteristics and see what it is capable of.

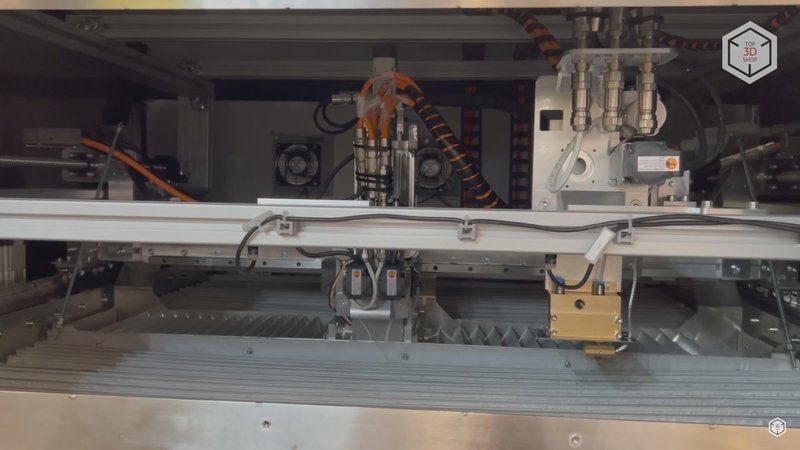

The build volume of the device is 600 x 420 x 300 mm, and it supports up to 4 interchangeable printheads. Equipped with a heated print bed and an extruder that can reach a maximum temperature of 270 °С, the machine features a minimum layer thickness of 60 microns.

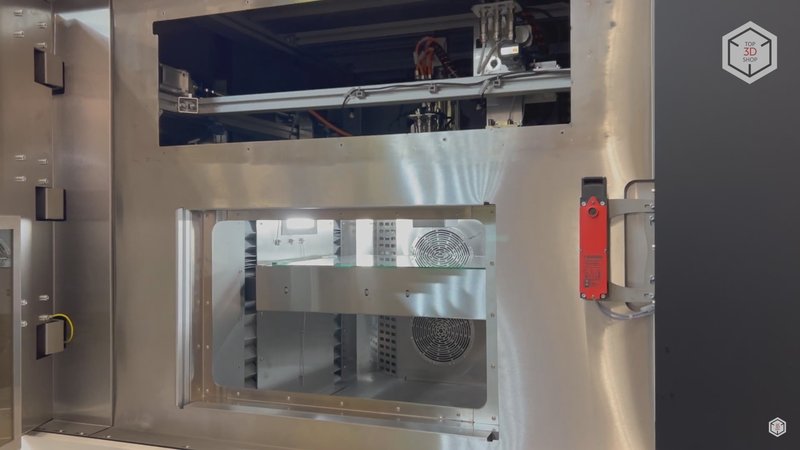

The manufacturer offers a modification: the company’s engineers have developed a high-temperature liquid-cooled extruder capable of heating up to 410 °С, and designed for printing with such plastics as PEEK, PEKK, and PEI. In addition, an active heating system for the print chamber reaching up to 160 °С is available as an option.

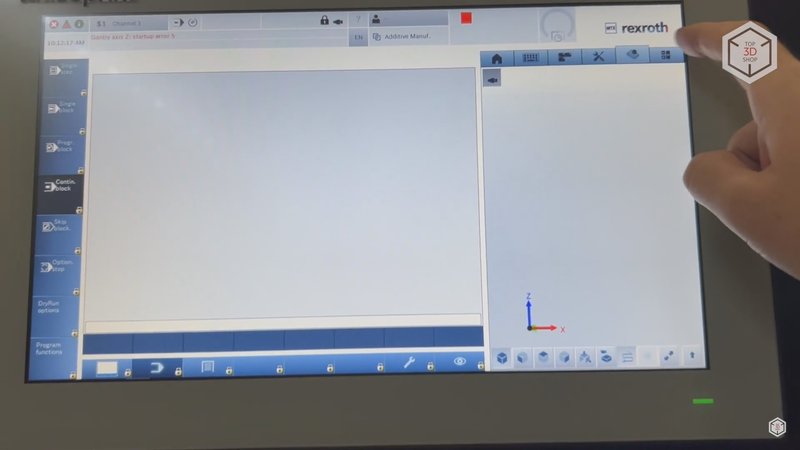

The unit is equipped with a filament supply sensor and has a drying chamber for two filament spools. Also, it boasts a Wi-Fi module and a built-in camera for online monitoring of the printing process. A large touchscreen is used to control and monitor the machine’s operation.

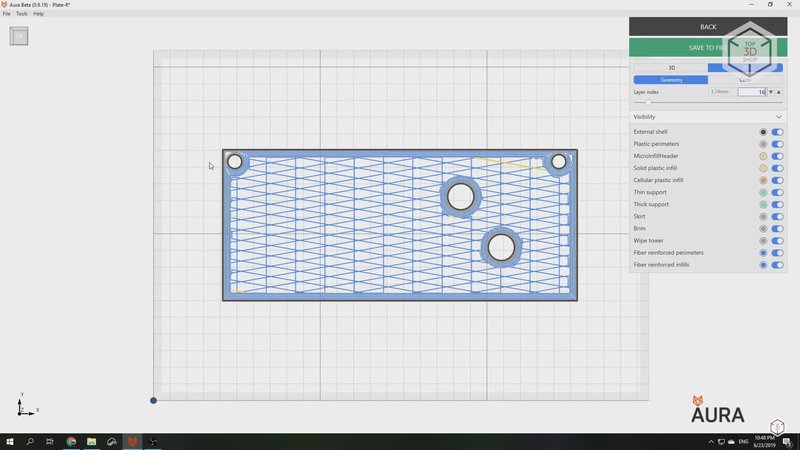

Anosiprint’s proprietary Aura slicing software is used to render files for printing. The software allows you to prepare jobs both for the conventional FDM method as well as Composite Fiber Co-Extrusion, developed by Anisoprint. The slicer not only automatically generates reinforcement algorithms for each of the layers, but also allows the user to easily change them. The transfer of files for printing is carried out via a USB or Ethernet connection.

The ProM IS 500 is compatible with third-party materials. Users are required to purchase a special license for the Aura slicer to gain access to processing generic filaments on the machine.

Thus, the ProM IS 500 is an open system designed for 24/7 industrial operation in aerospace, automotive, robotics and medical applications, significantly simplifying and speeding up the production of parts with an optimized internal structure and unique mechanical properties.

The following items clearly demonstrate the printers’ enhanced capabilities in manifold spheres:

Reliable and potent, the ProM IS 500 lets you print composite lattices granting optimal structures and mechanical properties. It delivers light performance parts reducing printing costs and production times. It can be used to produce a variety of strong yet lightweight fiber-reinforced composite 3D models, including spare parts, end-use tools, functional prototypes, and more.

Update your browser to view this website correctly. Update my browser now

Write a comment