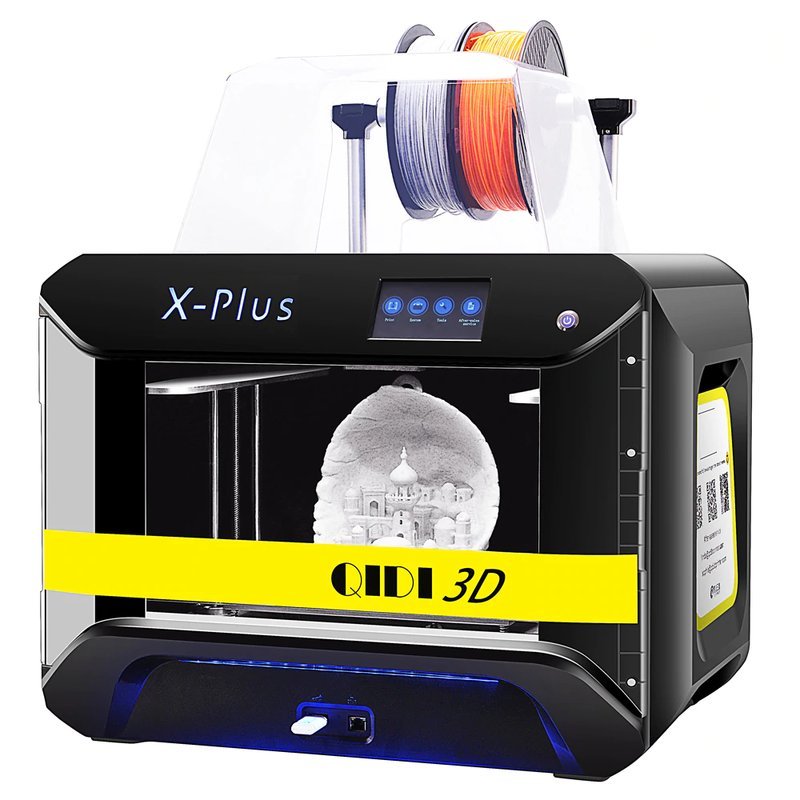

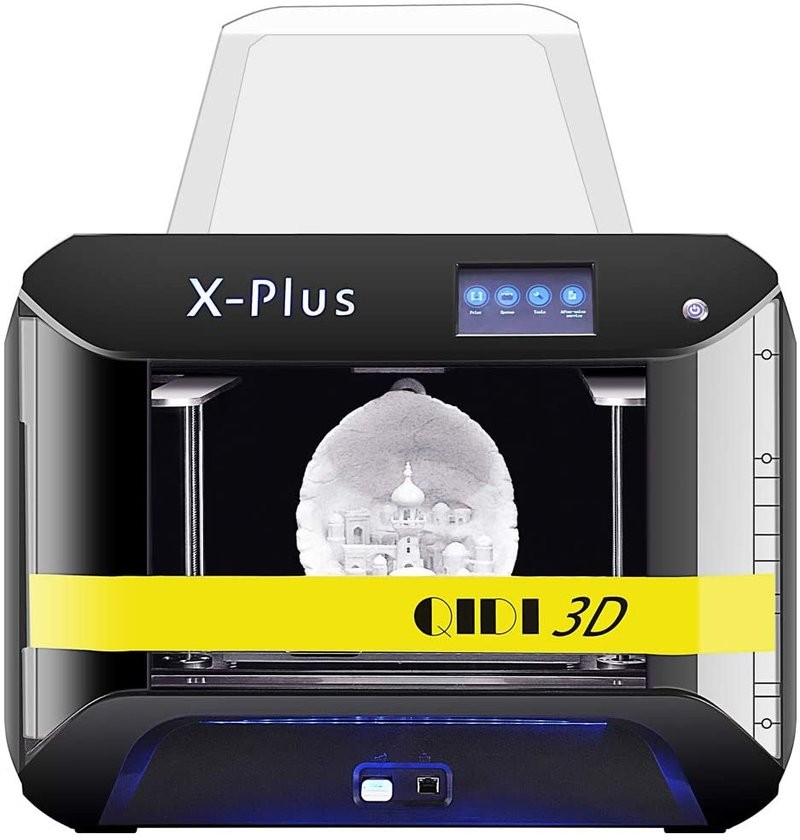

Hi everyone! Today, we are reviewing the QIDI Tech X-Plus 3D printer. Produced by QIDI Tech, a Chinese manufacturer dedicated to the development of professional-grade 3D printing devices for the consumer market, the QIDI X-Plus stands out for its sturdy design, smart functionalities, and efficient extrusion equipment.

As a QIDI Tech product, it has been designed to effectively combine affordability and usability. That’s why with $850 you get two exchangeable extruder setups, two spool holder configurations, a removable build plate, filament runout sensor, power-loss recovery, and a large 4.3-inch touch screen.

In this review, we are going to analyze the specs and features of the QIDI Tech X-Plus to find out if it achieved the goal.

Enclosed in a metal structure with acrylic side covers, the QIDI Tech X-Plus is a good-looking, stable machine that weighs around 23kg. Firmly fixed on its 4 rubber feets, it benefits from steady movement of both the drive mechanism and tool head.

It can hold the filament spool both on the inside of the print chamber and on the outside, atop the device. Depending on the material selected, you can go for ventilative or constant-temperature 3D printing. Also, you are free to choose the best extruder that suits your needs between the standard 250°C one and the high-temperature one.

Operated via a responsive touch screen, it is part of a comprehensive ecosystem that also includes the self-developed, easy-to-use QIDI Print slicing software.

The X-Plus is a plug-and-play semi-professional 3D printer that lets anyone produce quality prints right off the bat. So, if you are seeking an intuitive 3D printing device capable of delivering high-resolution parts without the need for design tweaks or upgrades, the Xplus is your choice.

Before analyzing the X-Plus features, let’s have a quick look at its specifications.

The X-Plus has a fully enclosed design composed of an inner metal structure, a plastic shell, and acrylic closing panels. The machine is factory assembled. Being an FDM (FFF) 3D printer, it melts filaments of thermoplastic materials and extrudes them through a hot end in a pattern. In this way, it produces 3D objects composed of multiple layers of fused filaments bonded together.

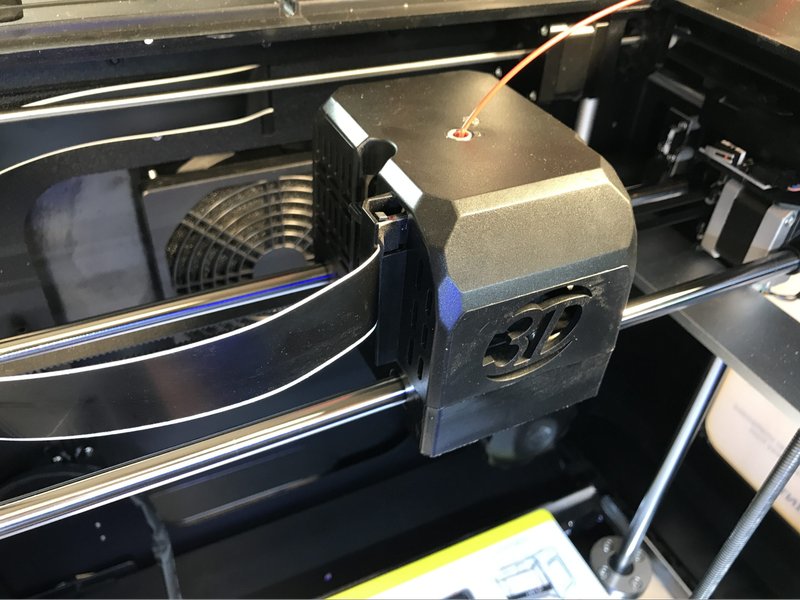

The extrusion process happens inside a Direct-Drive single extruder equipped with a 0.4mm nozzle. The filament must measure 1.75mm in diameter. For depositing the melted material, the print head moves on the X and Y axes, while the bed goes down vertically.

With a minimum layer height of 50 microns, the device allows producing end-use parts with smooth surfaces rich in detail. Setting a greater height speeds up the printing process but results in a slightly lower resolution.

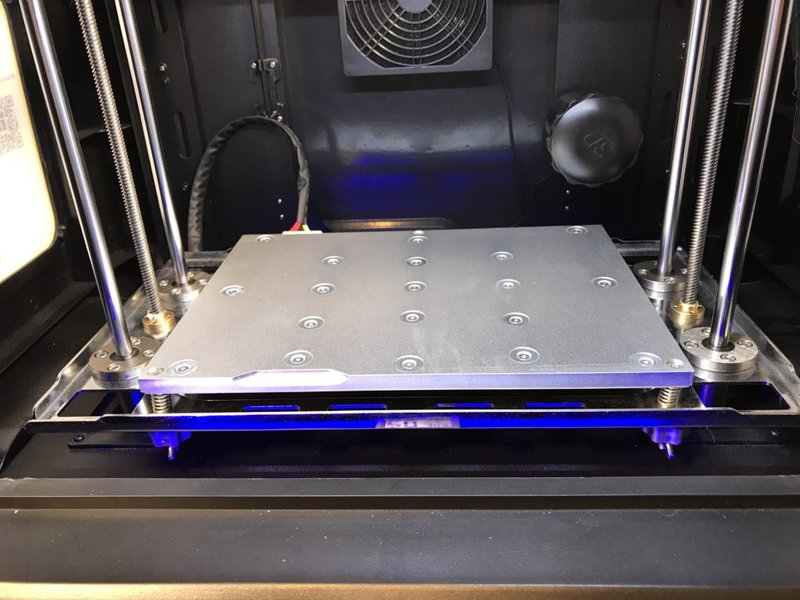

The QIDI Tech X-Plus has a decent build area of 270 x 200 x 200mm. This lets you produce medium-to-large parts without the need for splitting them into multiple sections. The print layers are deposited on a heated platform covered with a detachable build plate coated on its two sides.

Equipped with a power-off recovery function and an end-of-the-filament sensor, the Xplus prevents the risk of printing failures due to a sudden loss of power supply or material run-out. These smart features alongside the Wi-Fi connectivity enable standalone, unattended 3D printing.

Source: drucktipps3d.de

Due to its movement, the print bed requires calibration from time to time. Despite being manual, the leveling process is straightforward. The fitted touch screen helps you during the operation offering two assisted calibration options: quick and normal.

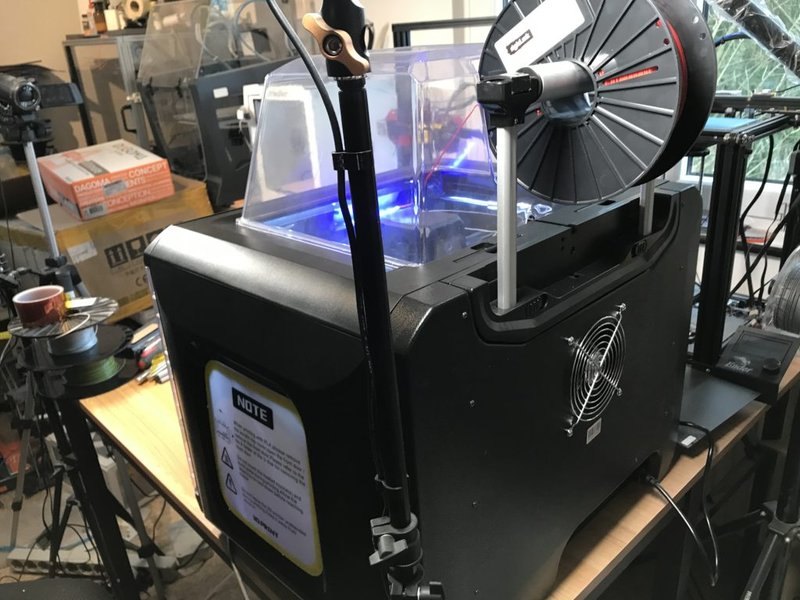

A LED lighting system illuminates the interior of the print chamber, giving you the opportunity to constantly check the print progress. Also, it comes in handy when calibrating the bed or installing the filament reel on the internal spool holder. A quiet filtered fan is mounted on the back of the structure. It helps to keep the printing environment healthy.

Source: drucktipps3d.de

The X-Plus has two different spool holders. By mounting the coil inside the chamber, the filament will benefit from a constant printing temperature and a moisture-free environment. The second holder, placed on the upper side of the machine back, is ideal for printing with PLA-like consumables. It can hold up to three spools.

The printer comes with two extruder units, one aimed at standard filaments, the other one aimed at high-temperature ones. This versatility makes the QIDI X-Plus ideal for semi-professional applications.

The technical support provided by the manufacturer is second to none. They are ready to help you troubleshoot your device in case of need. Also, you can find lots of tips and answers to your questions in a variety of 3D printing forums, such as Thingiverse and Reddit.

The printer comes packed in a strong cardboard packaging that contains a styrofoam box with all the accessories, the printer itself, and two side panels.

The packaging also contains a basic toolkit, which includes clips, nozzles, pipes, and a screwdriver. The glue stick is provided to help bed adhesion if required. The user manual is easy to follow. It includes text and images that clearly inform you about the parts list, unpacking process, and setup.

The package might not include the second Direct-Drive high-temperature extruder, which can be required via email. The printed letter included in the shipping box explains how to reach out to the company to get your high-performance extruder free of charge by post.

The printer comes mostly assembled. After removing the printer and its parts from the box, you only have to take out the protective accessories, install the external holder on the retractable clasps, and put the side covers in place if required.

Feeding the filament and calibrating the bed are the only two mandatory operations you should do before launching your first print. Following the instructions on the screen and using the leveling paper provided let you easily calibrate the print bed by tightening its knobs.

For the first calibration, it is recommended to select the normal process. For further calibrations, you can go for the quick leveling process.

This thorough video shows the unboxing and setup of the QIDI Tech X-Plus. The overall process generally takes less than 20 minutes.

The printer is large and heavy but can be easily managed by a single person. The inner structure is composed of alloy and steel, while the outer case is made from thick plastic. The print head runs on linear rails.

Source: drucktipps3d.de

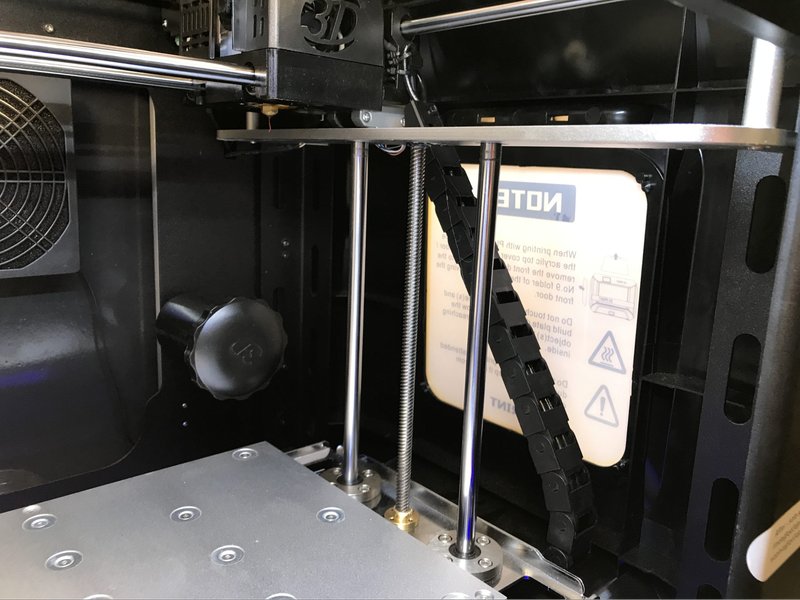

The bed and the build platform are both made of aluminum. The double Z-axis system relies on two 10-mm-thick gantry rods made of stainless steel. It also includes a worm drive of 8mm in thickness. The cables are housed in a cable chain, which protects them reducing the risk of damage. This also makes for a cleaner look.

Source: drucktipps3d.de

The double-sided build plate is made of spring steel and is held in place by 19 magnets. The black surface lets you print high-temp filaments up to 300°C. The possibility to remove the plate from the print chamber lets you easily pop off the completed prints.

Source: drucktipps3d.de

The device comes stock with a direct-drive extruder that heats up to 250°C. The standard extrusion unit can be easily upgraded to the additional high-temperature module provided, which reaches up to 300°C.

The printer offers the possibility to feed the filament either from the inside of the chamber or from the outside. The internal holder is mounted on the back panel, the external one is supported by two pull-out lock-into-place clasps placed atop the device.

Source: drucktipps3d.de

When printing with temperature-sensitive materials, it is better to close the semi-open frame with the magnetic side panels.

On the front of the printer, an on/off button lets you turn on the machine while the 4.3-inch touch display with icon interface lets you comfortably operate it. On the bottom, the USB and Ethernet connection ports enable computer direct control or standalone printing via USB stick.

Source: amazon.com

The QIDI X-Plus weighs 23kg and measures 710 x 540 x 520 mm. Its steady construction makes for precise and stable operation.

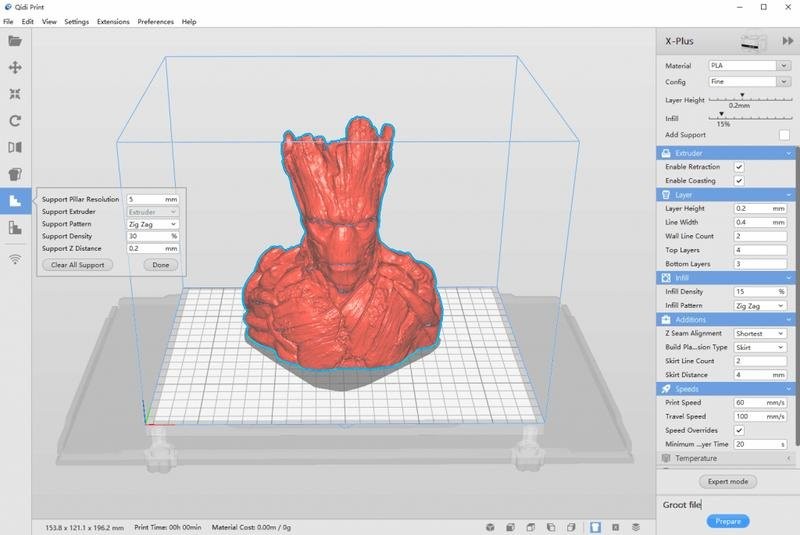

Like all the QIDI 3D printers, the X-Plus comes integrated with the proprietary QIDI Print slicer. The program is easy to use and intuitive. It is based on the popular Cura Slicer and provides most of the features of its counterpart.

However, the Xplus is an open-source device. It is compatible with the most common slicing software available. Depending on your printing needs, you are free to use the brand program or third-party ones, including Simplify3D and Repetier-Host.

As for the firmware, the X-Plus runs a version of Sailfish. The firmware works smoothly. However, in case of printing issues, you might reach out to QIDI Tech to require an update. They will provide you with all the necessary info and files.

Thanks to the two different extruder equipment, the X-Plus can process both consumer-grade filaments, including PLA, ABS, PETG and TPU, and specialty filaments, such as Nylon, PC, and Carbon Fiber.

Specifically, the 250°C extrusion unit is suited to standard materials, while the high-temp one prints with advanced thermoplastics. The Direct-Drive feeder helps when printing with flexible and soft consumables, while the enclosure is particularly suitable for printing with temperature-sensitive filaments like ABS.

Source: youtube.com

The dual-coated bed heats up to 100°C. It can be used in two ways, providing good adhesion with both types of materials. The white coating works with low-temperature filaments, while the black one with high-temp ones. The maximum printing temperature is 300°C.

Source: drucktipps3d.de

The open-source nature makes it compatible with 3rd-party filaments.

Pros:

Cons:

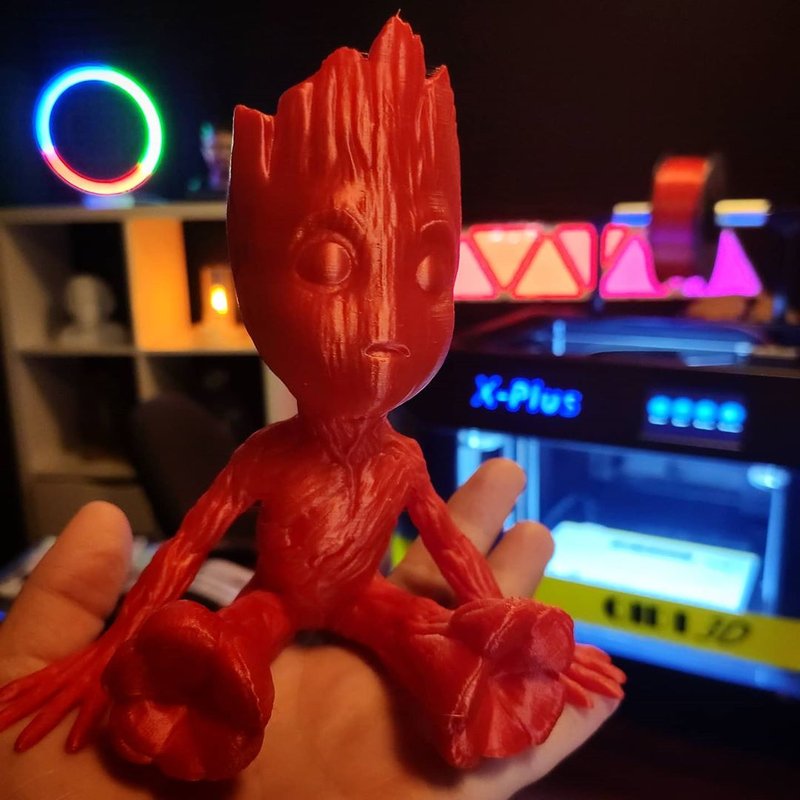

While allowing to print relatively large models, the printer is stable enough to provide great quality with fewer defects. Let’s take a look at some of the models printed on QIDI Tech X-Plus.

Source: Instagram.com

The QIDI Tech X-Plus is a performance desktop 3D printer targeted to semi-professional users and with a consumer-friendly price. The build volume of 270 x 200 x 200mm, the 50-micron layer resolution, and the temperature-controlled environment allow producing quality parts hassle-free. The device ships with two interchangeable extrusion units. The high-temp extruder is a nice upgrade for those who want to print and experiment with advanced filaments (Nylon, PC, and more).

Factory assembled and simple to use, it can be easily operated by anyone with no particular skills. Whether you are a newbie or a seasoned user, the X-Plus might be a great bang for your buck. Purchase it with us to gain a warranty and the best customer service.

Update your browser to view this website correctly. Update my browser now

Write a comment