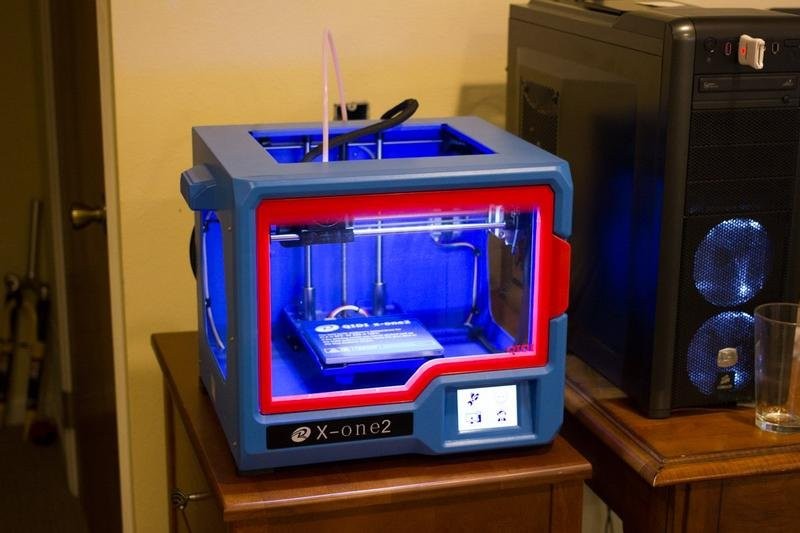

The QIDI Tech X-one 2 is a personal 3D printer manufactured by QIDI Technology, a Chinese company well-known for developing and marketing a variety of affordable yet versatile 3D printing devices. Aimed at both personal and semi-professional use, QIDI 3D printers are broadening access to the 3D printing world.

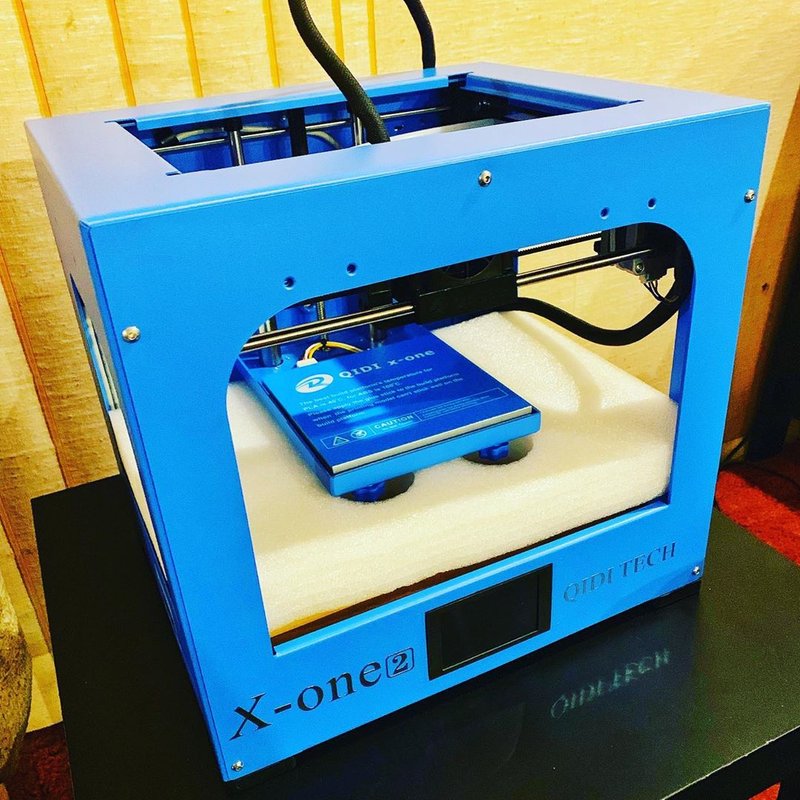

The QIDI X-one2 is an improved version of the X-one. Like its predecessor, this plug-and-play printer ships fully assembled and is ready to print just after unboxing. Its partially-enclosed design makes it stable, safe, and quiet. It is a budget machine that includes a set of quality-of-life features difficult to find in other 3D printers in the same price range.

Read our QIDI Tech X-one 2 review to learn more about its specs and capabilities.

The QIDI Tech X-one 2 is a budget semi-enclosed 3D printer that lets you produce decent quality parts with a build size of up to 150 x 150 x 150 mm. Despite offering a smaller volume than the average, this easy-to-use, low-price 3D printing device is engineered with a heated bed, a direct-drive single extruder, and a print recovery system. Also, it can be closed to benefit from a temperature-controlled build chamber.

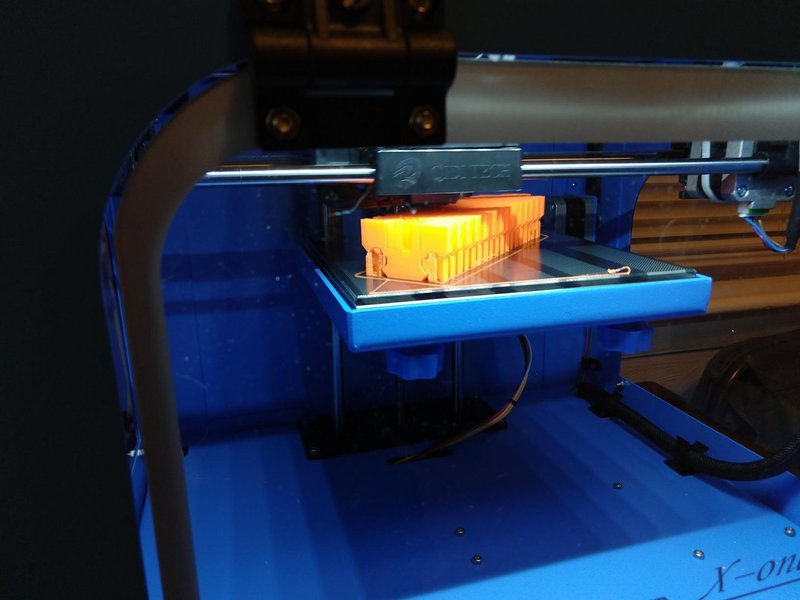

When fully enclosed, it allows printing with temperature-sensitive materials like ABS, always delivering good quality outputs. When open, the ventilated environment lets you successfully print with PLA-type filaments.

Safe and extremely simple to operate, the X-one 2 is perfect for newbies, kids, and students.

Before going deeper into the X-one 2 specifications, let’s have a look at the following overview.

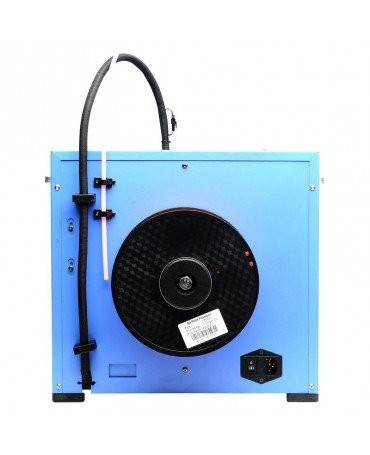

The QIDI Tech X-one2 is a 3D printer with a partially enclosed metal structure. The front and side openings can be closed by attaching the provided acrylic panels to the case. The printer is shipped assembled. Setting it up is straightforward. You just have to install some minor components (panels and filament spool), as it happens with most pre-assembled devices.

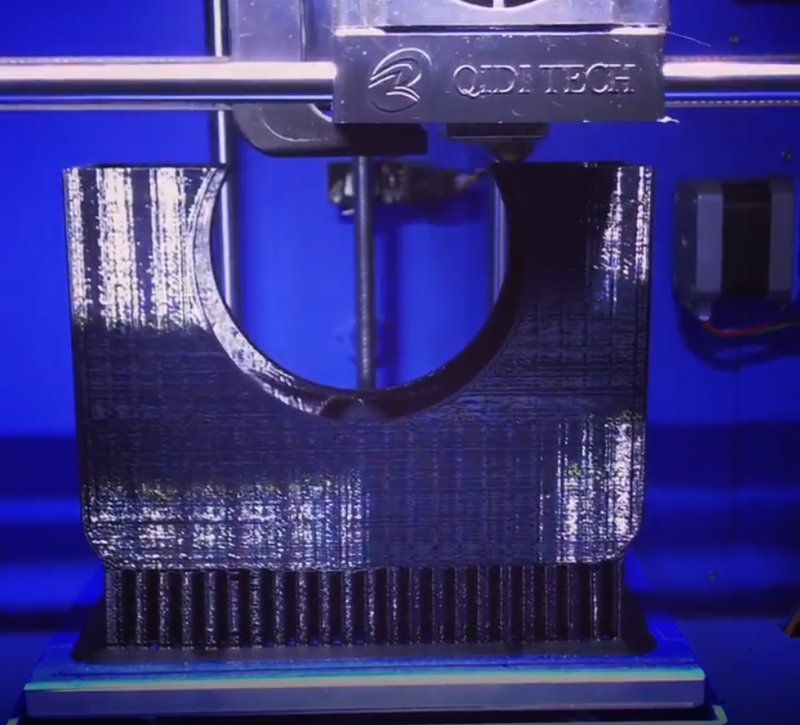

The printer uses Fused Deposition Molding technology, a printing method based on the extrusion of melted thermoplastic material through a nozzle, which in turn moves over a heated building platform. The X-One 2 adopts a 0.4mm extrusion nozzle that can heat up to 250°C. The extrusion unit is engineered with a Direct Drive feeder system, which differs from the Bowden one in the position of the extruder motor. In particular, in the Direct Drive mechanism, the motor is mounted right on the top of the hot end, reducing the travel distance of the filament. It is ideal for effectively printing with flexible materials.

The device prints with filaments of 1.75mm in diameter. This gives you plenty of material choices because they are currently the most popular consumables on the market.

Source: Instagram.com

For printing a layer, the print head moves in the space following the X and Y coordinates collected in the print file. After completing it, the print bed moves down on the Z-axis and the head goes on printing the next layer. This type of movement relies on the Cartesian coordinate systems, which uses these three numbers (X, Y, and Z) to determine the position of a point in the space.

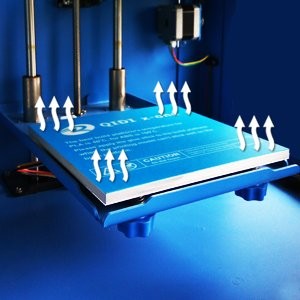

For printing with materials other than PLA, the X-one 2 has been equipped with a heated metal bed covered with a BuildTak-like PEI surface. The build platform reaches 110°C. The print bed must be calibrated on first use and from time to time. The leveling process is manual and can be performed using the three knobs placed below the platform and the included leveling paper. The calibration is quite simple.

Source: www.amazon.com

The printer has a build volume of 150 x 150 x 150mm.

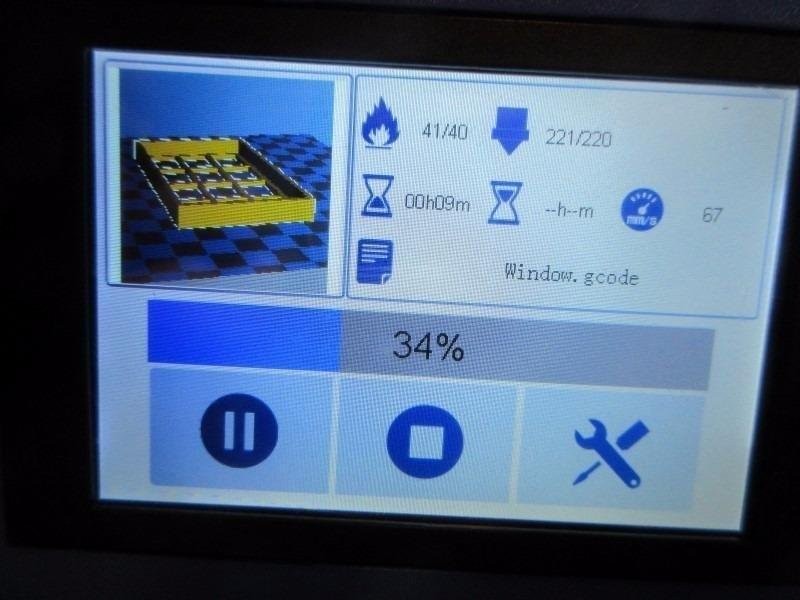

The X-one2 comes with a 3.5-inch touch screen, which allows controlling most printing settings. It also keeps you updated about the printing status showing the progress percentage, the printing time, as well as the estimated time remaining. It makes printing a breeze if compared to the knob interfaces of similarly priced devices.

The printer includes a print recovery feature. It prevents printing failures caused by sudden power loss, giving you the possibility to restart the print job exactly from the breakpoint. Considering the low price tag, it is a nice-to-have function.

The possibility to close the entire structure is perfect when printing in small spaces or with kids around.

The 3D printer is packed inside a cardboard box that is in turn packed inside another box. The multiple packaging accurately protects the machine during transportation.

Here is the list of parts you get after unboxing the QIDI Tech X-one 2.

Source: instagram.com

The amount of tools and spare parts the printer comes with is pretty decent. Everything you need to start printing and to maintain the device is included.

As already mentioned, this QIDI 3D printer comes mostly assembled and requires minimal setup. The only thing you need to do is install the spool holder, attach the filament guide, and calibrate the bed. The device will be ready to print in around 10/15 minutes.

The user manual that comes with the printer is clear and concise. Also, the provided SD card includes helpful video tutorials that show how to perform specific tasks. It also contains an unpacking video, which is not very useful to watch after unboxing the printer. However, this and other videos are also available on the official QIDI 3D printer youtube channel.

If you are curious to see the X-one 2 unboxing and setup process, just watch the following video.

The QIDI X-one 2 is a robust machine with an all-metal rigid frame. Built like a tank, it resists flexing and wobble. It is equipped with a single Direct-Drive MK10 extruder with 0.4mm nozzle. The filament spool is mounted on the back of the device.

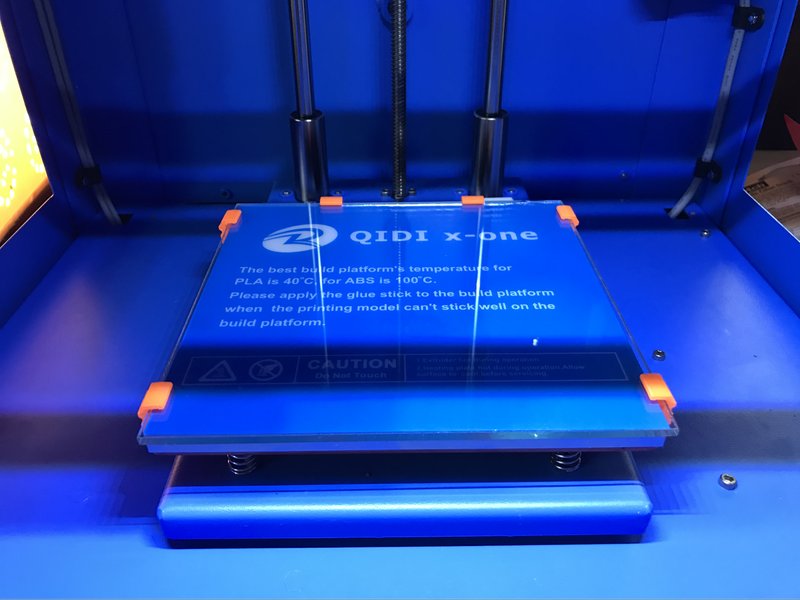

It features a sturdy, flat, and easy-to-level build platform made of aluminum. The bed is covered with a blue coating, similar but cheaper to the well-known BuildTak surface. The bed is heatable.

This short video shows how to comfortably level the build plate.

Unfortunately, the QIDI X-one 2 is a little bit loud. Nevertheless, the front and side plastic panels keep out air drafts, dust debris and reduce the noise. Inside the build chamber, some useful lights improve print monitoring. Sad to say that they can’t be turned off.

The 3.5-inch responsive touch panel has an intuitive interface. When printing with the provided QIDI slicer, it shows a preview of the 3D model before starting the print.

Source: amazon.com

The printer's external dimensions are 380 × 320 × 360 mm. It weighs 19 kg.

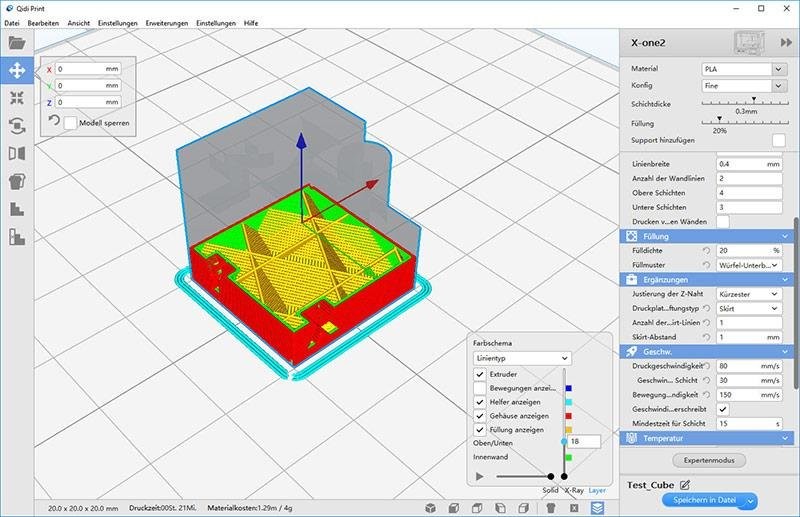

The printer comes stock with QIDI Print Slicer, the proprietary slicing software designed on the basis of Cura slicer. The program relies on an effective model segmentation technology and comes packed with a set of thoughtful features.

Easy and convenient to use, it works really well with the X-one2 and is compatible with the most common 3D file formats, including STL and OBJ.

The proprietary software is adequately simple to use. However, if you prefer using a different slicer, such as Simplify3D, you can do that.

The X-one 2 adopts the Sailfish firmware, which works pretty well. In case of issues or questions, the great customer service - one of the flagship of the QIDI Tech company - has got you covered. They will help you update or fix your firmware improving your printing capability.

The direct-drive single extrusion system along with the heated print bed allows printing with a range of consumer filaments, including PLA, ABS, PETG, and flexible materials.

The hot end heats up to 250°C, while the metal plate reaches 110°C. The BuildTak-like blue PEI coating grants optimum first layer adhesion.

When printing parts with large bases, it might be difficult to remove the complete print from the plate. In those cases, adjusting the Z offset, waiting until the plate cools down and heat it again might be helpful.

Source: amazon.com

The QID X-one 2 has an open material system that makes it compatible with materials from any vendor.

The QIDI X-one2 works well right out of the box. Like other 3D printers, it supports a variety of upgrades and mods aimed to enhance its capabilities.

The first upgrade you might consider is replacing the build plate. When printing at high temperatures (around 110°C) for a while, the blue sheets of the stock bed might come loose. Switching to a glass bed might improve your printing experience solving that issue and making for better adhesion and smooth surface finishes.

Source: imgur.com

The glass bed can be held in place by self-printed clips. Here you can find some 3D printable files for free.

Upgrading to an all-metal hot end is also very common. Despite the stock extruder works really fine, swapping to an all-metal hot end gives you the possibility to print with advanced filaments. Then, if you are planning to experiment with your QID Tech X-one 2, this mod is right for you.

In this video, you can see how to upgrade to the Micro Swiss hot end.

Some additional minor tweaks might give your X-one2 greater versatility, increasing its final score.

Pros:

Cons

Qidi Tech X-One 2 provides a decent quality for a good surface finish. Take a look at these models:

Summing up, the QIDI Tech X-One 2 is a good quality, flexible 3D printer, which is sold at a convenient price. Despite its tiny build volume of 150 x 150 x 150mm, it delivers good quality print with a resolution of down to 50 microns straight out of the box. It benefits from a print recovery feature and a responsive touch screen. The open system makes it upgradable and hackable.

All the issues it might stumble upon can be easily fixed with the prompt help of the excellent customer service.

On the whole, the X-one2 offers good value for the money. It is perfect for rookies and tinkerers who are looking for a simple-to-use 3D printing device on a budget. You can buy the printer from Top 3D Shop.

Update your browser to view this website correctly. Update my browser now

Write a comment