FFF/FDM printing has been affordable for quite some time, but in recent years, this technology has become even cheaper. Its main advantages are scalability and material variety — even inexpensive 3D printers can offer support for a wide range of filaments.

In this article, we will talk about the Qidi Tech X-Max, the new addition to the series of 3D printers by a Chinese company Qidi Technology. While this device might be slightly more costly than the other products of the brand, it’s still very affordable and offers enough functionality and unique features. These will be explained and described in depth.

Qidi Technology is a Chinese company based in Ruian, Zhejiang province. It was founded in 2014. This high-tech enterprise does a lot of R&D and marketing of their own 3D printers. The company has generated a lot of interest after successfully launching the Qidi Tech I in 2015. The majority of the brand’s products are inexpensive FFF/FDM 3D printers, although the Shadow 5.5, released in 2019, uses the MSLA technology and marks their first foray to the world of resin printing.

Qidi Technology is also known and respected for its timely customer support service.

When designing the X-Max, QIDI aimed at producing a high-performance 3D printer with a large build volume and broad material compatibility. That’s why they developed a device with a build area of 300 x 250 x 300mm and two swappable extruders targeted to different types of filaments. One hotend is tailored to standard consumables, while the other one handles advanced thermoplastics.

According to the producer plan, the printer had to be stable and reliable in order to grant the best user experience to their customers. The enclosed structure, the double Z-axis and the quality hardware along with the intelligent features and efficient customer support serve the purpose. Interior light, air purification, low noise, Wi-Fi connectivity and print recovery are some of the clever functions you will benefit from.

The QIDI X-Max features a heated bed with detachable magnetic build plates. Once calibrated, it maintains the level for long. Targeted to small businesses and makers, this enclosed machine lets you successfully complete your prints most of the time.

Source: amazon.com

Ok, but what are the cons? Well, the X-Max, like other FDM printers, might have some cons, of course. Nevertheless, they are not insurmountable and, in most cases, with a little tweaking and with the prompt help of the technical support, you will be able to find a viable solution in rapid times.

For example, in some cases, the firmware might wrongly calculate the print head positioning, causing bending. Updating the firmware might solve this issue. Someone experienced a problem with the flexible cable connected to the tool head, saying that it caught on the rods when printing large parts. The problem has been fixed using some tape to keep the cable away from the rods. Apart from these sporadic cases, one of the worst things that can happen is to receive a defective part. When it happens, QIDI support takes care of sending a replacement in the shortest possible time, often using express shipping.

That said, the QIDI Tech X-Max is one of the best large-format 3D printers available. It works better and costs less than devices with the same print area. Also, it is able to print with a wider array of filaments than the average consumer devices.

The QIDI X-Max uses Fused Deposition Molding technology to produce parts by melting a filament of thermoplastic. A Direct Drive motor placed on an extrusion unit pushes the filament through a heated hot end and a 0.4mm nozzle to deposit it on the build plate, layer by layer. While fusing the consumable, the print head travels on the X and Y axes following the sliced model paths. The build plate shifts down when the layer is complete.

Source: instagram.com

The material layers can measure from 50 microns to 400 microns in height. The thinner the layer the smoother the surface. This allows producing functional prototypes or end-use daily objects with a decent resolution. The printer comes with a standard extruder and a high-temperature one. The filament diameter supported is 1.75mm. The open material system allows printing with filaments from any vendor.

Source: instagram.com

The X-Max benefits from a recovery function, which lets you pause the device to replace the filament or restart a print job after a power loss. The machine is also capable of automatically shutting down when completing a print. However, despite its large build volume, it doesn’t include a filament detection sensor.

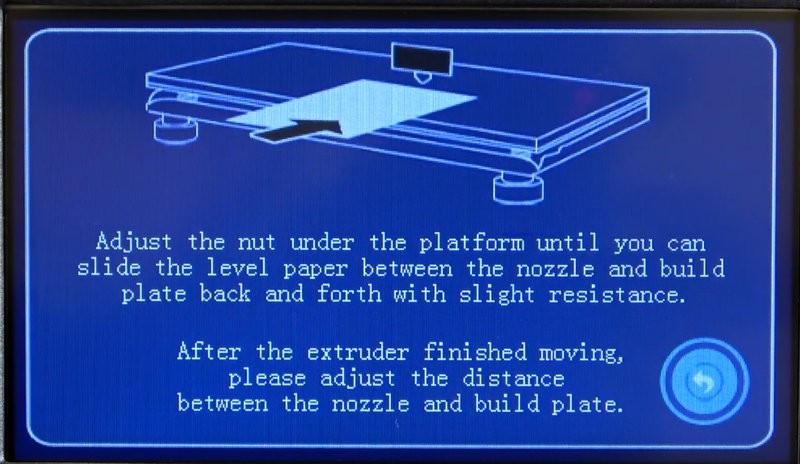

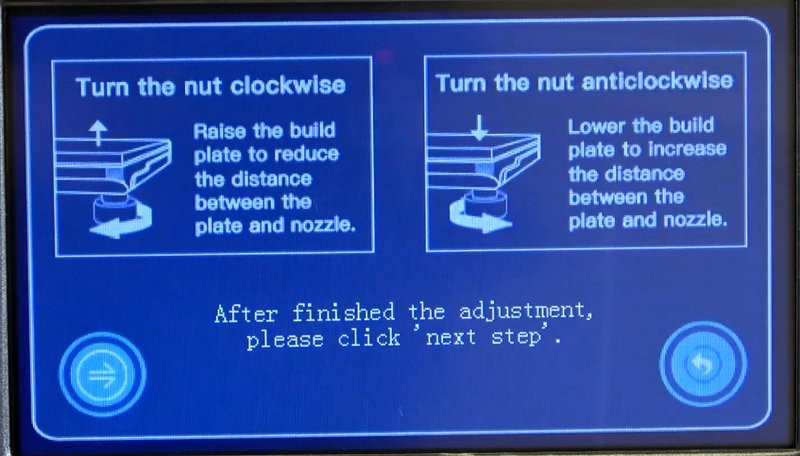

The assisted bed calibration facilitates the leveling process. Indeed, you only have to follow the instructions shown on the display to correctly calibrate the platform. The printer also offers an additional fast-leveling option for the automatic positioning of the nozzle on each point.

Unlike other QIDI 3D printers, the X-Max comes with an air filter for keeping the printing environment healthy. The internal LED lights allow monitoring the printing process even in the dark. The LEDs can be turned on and off through the fitted touch screen.

The operating display supports up to 6 different languages.

Source: qd3dprinter.com

The device comes pre-assembled. It’s neatly packed, with most of the contents of the box being safely placed inside the printer, which prevents them from being damaged. Unboxing the X-Max might require some help, as the machine is rather heavy at around 30 kg, which means that moving it alone is going to be troublesome.

The initial setup consists of assembling the external filament reel and placing it on top of the device.

Source: youtube.com

The package contains:

After unboxing the device, you’ll only have to remove the paddings and the lid cover from the inside of the printer, plug in the machine and lift up the bed to remove all the protective foam. Then, calibrate the platform, install the filament, and enjoy your new printer.

The unboxing and setup process takes 15 minutes or less. It is extremely easy even for newbies.

The printed guide illustrates how to assemble the printer and how to use the proprietary slicer. It is more than enough to successfully build the printer. However, watching this video tutorial might come in handy.

The package also includes detailed instructions on how to replace the extruder. QIDI also released this short video to better explain the process.

The USB stick that comes with the printer contains troubleshooting video guides, QIDI slicer with profiles, and some solution videos of common issues.

After putting all the parts in place which would take a couple of minutes (since the machine is delivered pre-assembled and the user only need to put the filament reel on top of the device and optionally push the filament through the guide tube), the first step after powering the X-Max would be to level the bed.

Press the ‘Leveling’ button on the touchscreen.

Source: youtube.com

Select the ‘Normal leveling’ option if you’re using the printer for the first time. The ‘Fast leveling’ is better to be left for the future.

Source: youtube.com

Follow the recommendations that appear on the screen.

Source: youtube.com

Source: youtube.com

It’s recommended to go through the procedure a couple of times just to be sure.

The next step would be loading the filament into the extruder. To do so just press the ‘Filament’ button on the main screen.

Source: youtube.com

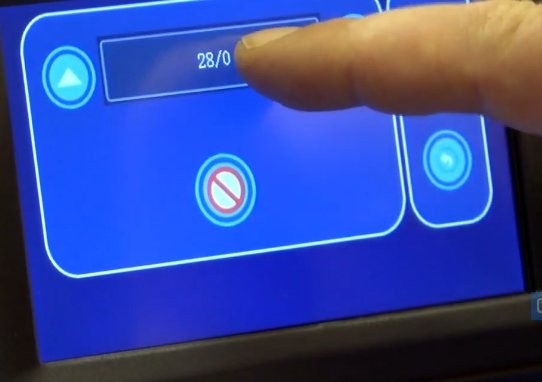

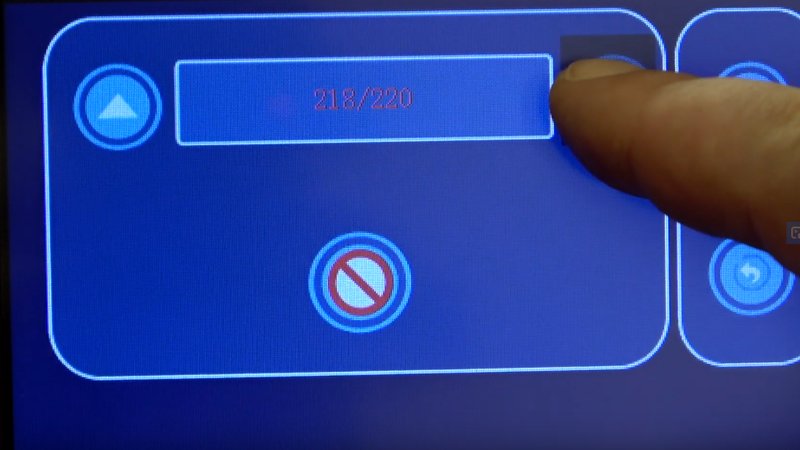

After that you will be presented with the number that shows the filament temperature. Simply press on it and see the temperature increase.

Source: youtube.com

Once it reaches the top temperature of 220 °C, press the downward arrow button. It will push the filament through.

Source: youtube.com

After some time you will see the extruded filament. Let it run for a few seconds and then press the red circle, so the extrusion will stop. After that press the numbers again, so they’ll start to drop and the temperature will return to a normal cold state.

Source: youtube.com

Now the machine is ready.

Get the USB thumb drive that came with the package, connect it to the 3D printer and try to print some pre-loaded models to check the quality before attempting to do serious printing..

Source: youtube.com

The X-Max comes with a robust and stable metal construction open on both the front and the upper side. The metal frame is covered by a plastic external shell. A transparent plexiglass door and a plastic hood complete the structure. The print head slides on a 10-mm steel rod.

The machine adopts reinforced cables that are accurately managed and sorted. The print head wires are combined into a single flat cable while the other ones are housed in the cable chain placed on the right side of the chamber. This makes for a safe and clean design.

To increase the stability of the bed, the printer is equipped with a 300mm dual Z-axis on either side. The dual rods make for steadier movement.

As for the extruder, the X-Max some stock with a QIDI Tech 3rd generation extruder designed for printing with generic consumer-grade materials. An additional high-temperature brand extruder is included in the package. A powerful turbofan effectively blows the air under the nozzle. Two enclosure fans are installed on the back of the printer. Additional fans with integrated filters are mounted inside the printer, on the back wall.

Source: amazon.com

The device features a 2mm folded steel sheet supported by a dual Z-axis lead screw and a heated 10mm-thick aluminum bed with a detachable steel build plate. Considering its thickness, the aluminum bed heats reasonably fast. Indeed, it can heat up to 70°C in around 5 minutes and to 120°C in 26 minutes.

The removable plate snaps on the aluminum bed magnetically. The dual coating makes it usable in two ways. The front side is coated with a BuildTak surface, which is ideal for printing with standard materials (PLA, ABS, PETG, TPU, etc.). The quality coating makes the print surface adhere well to the plate without using glue or hairspray. The reverse side of the plate with a combination of glue stick is aimed at advanced filaments (Nylon, PC, etc.).

The flexible plates can be easily bent to remove prints.

The QIDI Tech X-Max features two spool holders, one installed on the back wall inside the build chamber and the other one mounted atop the device. The upper holder is foldable. It can hold up to three filament bobbins. The internal spool holder keeps the material dry protecting it from moisture and dust. It is particularly suitable for filaments that require a dry environment, such as Nylon and similar ones.

Source: tobuya3dprinter.com

On the front top, a 5-inch touch screen gives you full control over the printing process. It has a user-friendly interface with large icons, which let you intuitively navigate the menu and manage the settings. The responsive display supports multiple languages.

In addition to standard print management settings, the control panel allows turning the lights on and off while printing, controlling the enclosure fans and setting the device to shut down after completing a print. Also, it provides a preview of the print model before launching the print.

The X-Max has both a USB and a LAN Internet socket. It also includes a Wi-Fi module for wireless connection.

The printer weighs about 27kg and measures 580 x 530 x 740mm. It can be installed on almost any desk table.

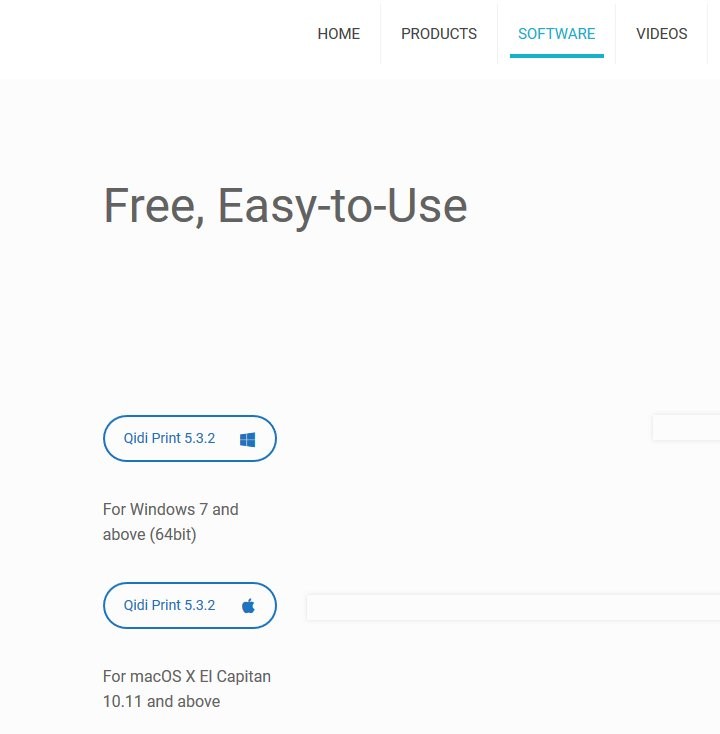

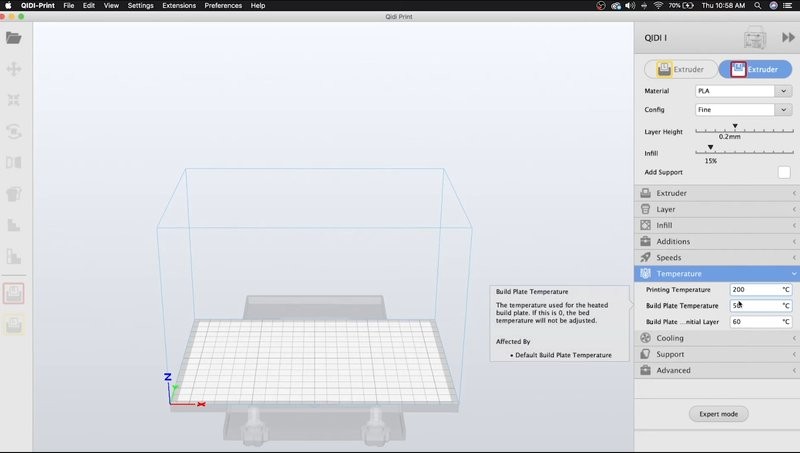

Qidi Technology provides its own Qidi Print slicing software to be used with their devices. The Qidi Tech X-Max 3D printer is also officially compatible with Cura (which isn’t surprising since Qidi Print is a modified version of it) and Simplify3D.

QiDi Print can be downloaded from the Qidi Tech website. There are Windows and macOS versions available.

Source: qd3dprinter.com

Being a mod of Cura, Qidi Print has mostly the same features, but is designed to work seamlessly with the Qidi Tech 3D printers.

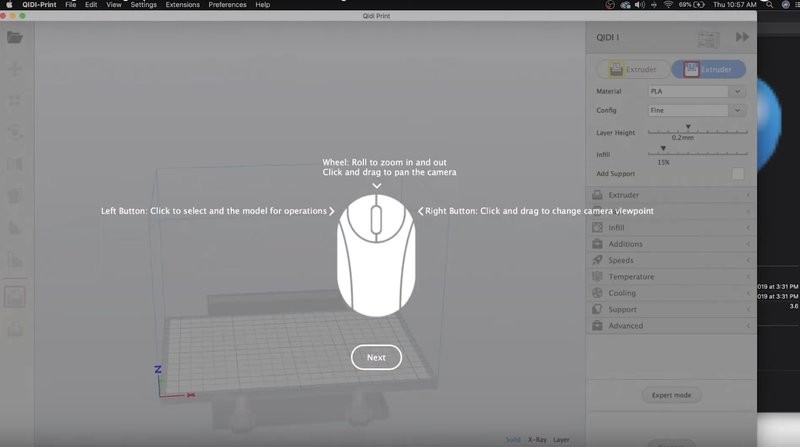

A little tutorial that pops up after downloading Qidi Print for the first time shows how to use the slicer.

Source: youtube.com

The interface is clean, intuitive, and straightforward while maintaining powerful functionality and explaining some elements.

Source: youtube.com

The X-Max runs a version of the Sailfish firmware. Depending on the version of the firmware you got when buying the device, you might need to update it to improve the printer capabilities.

The printer features a heated print bed that can heat up to 120°C and two different extruders.

The first extruder can reach a temperature of around 260°C. It is designed for printing with standard consumer-grade consumables. The second extruder has been developed for reaching up to 300°C. It features a hardened steel nozzle and can handle professional-grade filaments.

Depending on your needs, you can print in both a temperature-controlled closed environment and a ventilative environment.

When closed, the X-Max can process difficult-to-print, temperature-sensitive materials. Opening the door and leaving off the lid creates ideal conditions for printing with PLA-type consumables.

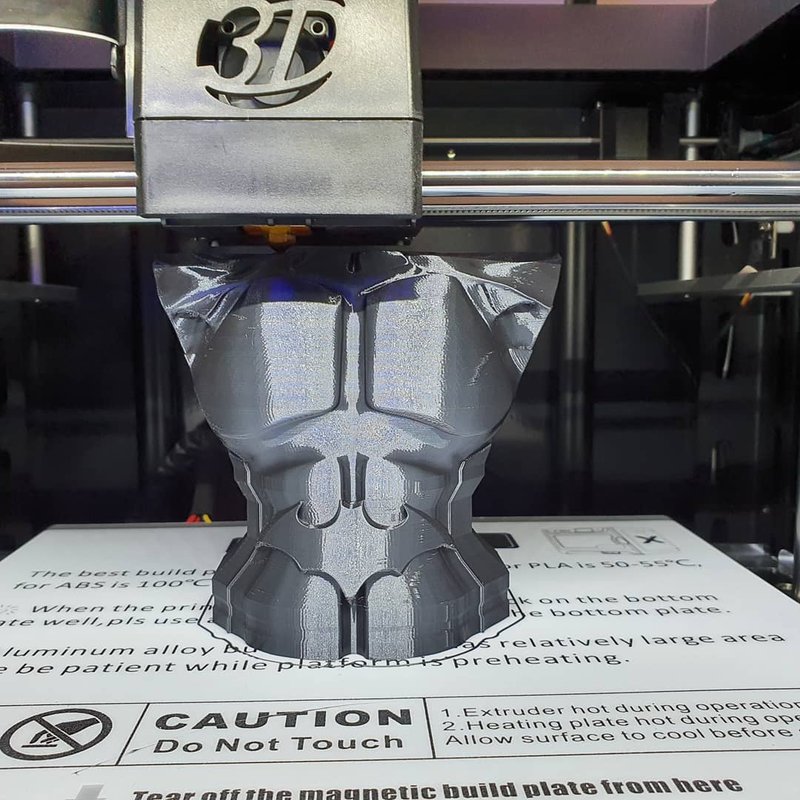

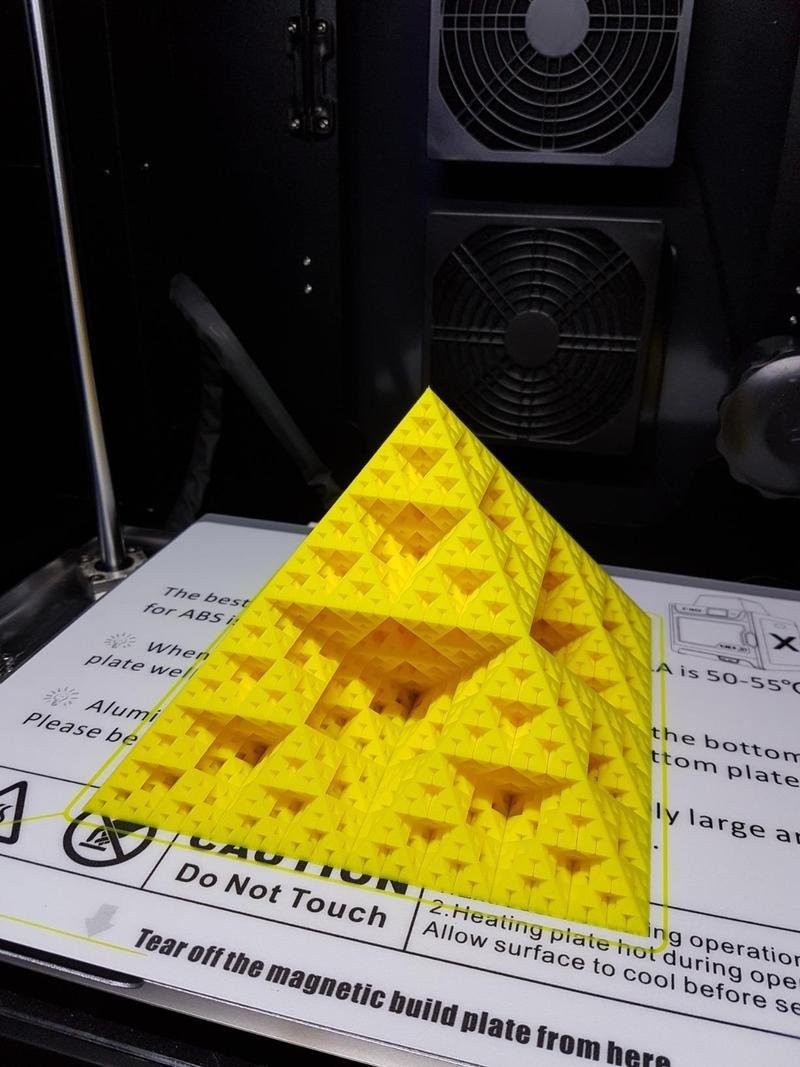

This 11-inch tall print showcases how detailed the prints by the Qidi Tech X-Max can be. The surface also has a nice finish.

Source: instagram.com

The level of detail on this work is incredible.

Source: amazon.com

This is a large model with smooth surfaces that turned out great.

Source: amazon.com

Despite being a consumer-grade desktop 3D printer, the QIDI X-Max comes with an interesting set of semi-professional features which are more than enough for personal and semi-professional use. However, more demanding users might want to upgrade some of its functions to broaden its capabilities.

In our experience, the main upgrade you should make is the addition of a filament run-out detection system, which is ideal when printing large parts.

In some cases, the filament might tangle up or slip off from the spool. To solve the problem, you might self-print a new spool holder.

The Qidi Tech X-Max is an affordable large-volume 3D printer. It’s a highly versatile tool, designed for working with an impressive number of filaments: from common ones, such as ABS and PLA, to demanding and exotic materials, such as Nylon and carbon fiber. This level of flexibility is achieved by the ability to handle high temperatures thanks to the device’s robust build and fully enclosed print chamber. There are also many features of the printer that allow for it — interchangeable extruders, two filament spools, and a two-sided print bed. The machine is also incredibly quiet, which is another advantage of using a fully enclosed construction combined with a well-designed cooling setup.

The print quality of the Qidi Tech X-Max is also great, the model is highly accurate and relatively fast. The heat is evenly distributed across the print platform and everything is adequately cooled when needed, which prevents many defects from occurring.

Of course, the machine is not flawless. The disadvantages include lack of both dual extrusion and filament runout sensors, the features that are common among the 3D printers of this price segment. It’s also quite big and heavy, arguably even more than it needs to be due to some design choices.

Affordable, quiet, with the roomy print chamber and support for an impressive range of materials, the Qidi Tech X-Max is a great choice for those who need a versatile device capable of producing large-sized prints using various filaments. Combined with the ease of use and a good number of high-tech features, the strengths of X-Max allow it to occupy the niche between the inexpensive 3D printers aimed at hobbyists and big pricey prosumer devices.

If you want to purchase a brand new QIDI X-Max, visit Top3DShop!

Update your browser to view this website correctly. Update my browser now

Write a comment