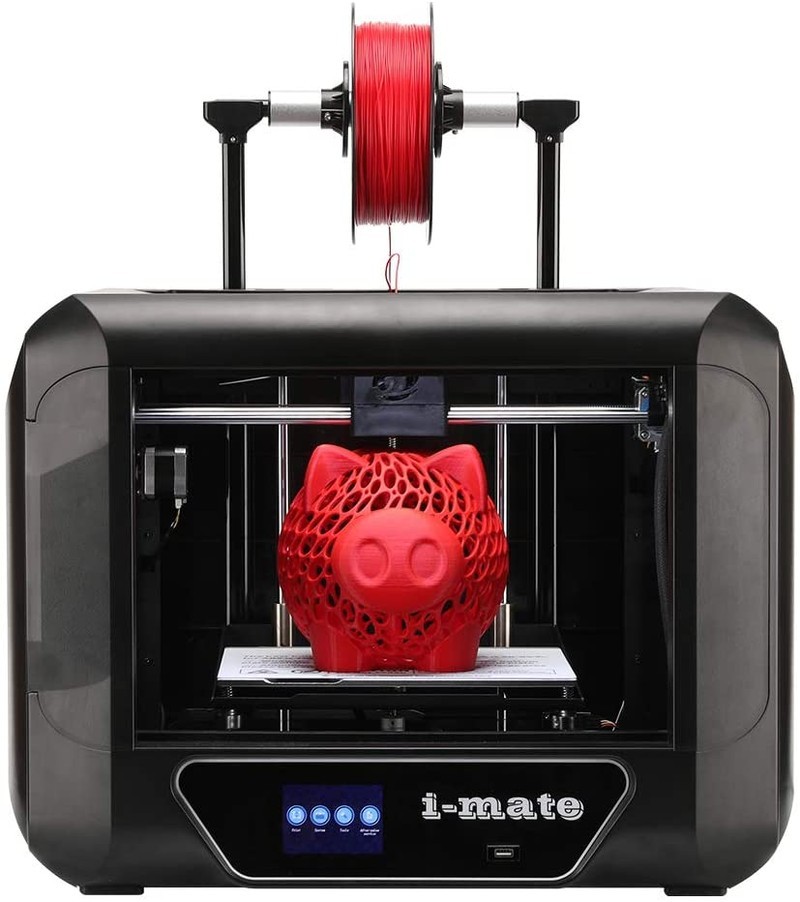

Greetings and welcome to the Top 3D Blog — a place where additive manufacturing enthusiasts meet high-quality knowledge and the most informative articles on the topic. The spotlight of this particular piece is taken by the QIDI Tech i-Mate. It is a smoothly designed semi-enclosed FDM 3D printer that comes at a sub-$350 price tag and offers decent build volume, Wi-Fi connectivity, and a handful of essential features for a seamlessly integrated printing experience. A beginner-friendly machine made with reliability in mind, just like a plethora of other devices available on the modern additive manufacturing market. Is there anything that really makes the i-Mate stand out? Read the article to find out.

QIDI Technology is a Zhejiang-based manufacturer of high-quality 3D printers. The QIDI i-Mate comes from the recently released i-lineup that also includes the i-Fast and i-Mate S. Unlike the i-Mate, its counterparts are fully enclosed and come at a higher price tag. Essentially, the i-Mate S is an upgraded version of the i-Mate that can reliably print tall parts with ABS, while the i-Fast is a semi-professional FDM 3D printer with dual extrusion system, extended build volume, and a plethora of other professional features.

Aside from producing entry-level and semi-professional resin and FDM machines, the company also takes pride in creating dedicated software and firmware solutions for their 3D printers. The company provides outstanding after-sales service and is known for its customer-oriented approach. To date, the company’s lineup consists of fourteen 3D printers that get exported to dozens of countries all around the world, which says a lot about their quality because high-quality goods are always in demand.

The QIDI Tech i-Mate is a semi-enclosed FDM 3D printer that offers a decent build volume of 260 x 200 x 200 mm (10.2 x 7.9 x 7.9 inches) and lets you shape a plethora of decently-sized items with millimeter precision. You can control the printer by using a responsive built-in touchscreen with a neat-looking UI. The machine can print at a maximum speed of 150 mm/s and can print layers as thin as 50 microns, which is impressive for a 3D printer that comes at a sub-$350 price tag.

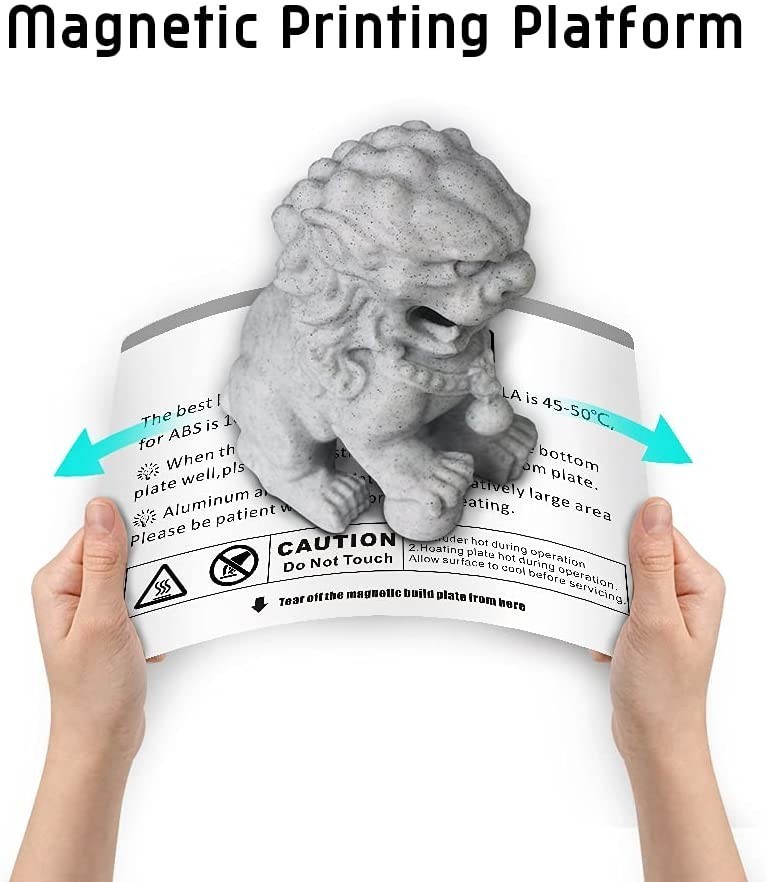

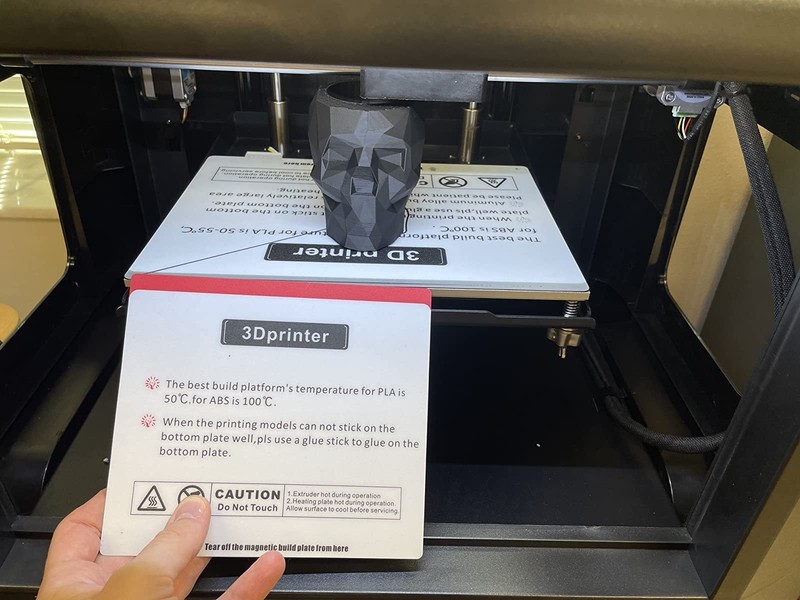

The machine is equipped with a detachable magnetic build platform supported by nine high-temperature magnets for increased responsiveness, better first layer adhesion, and hassle-free print removal. It can heat up to 120℃, which is impressive, to say the least.

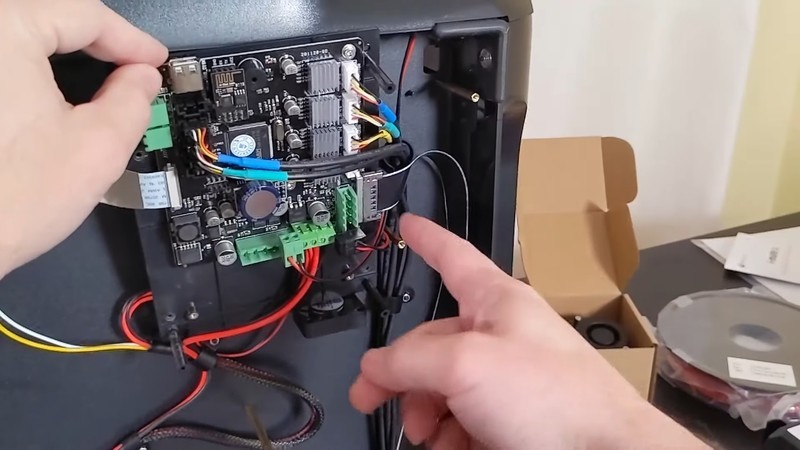

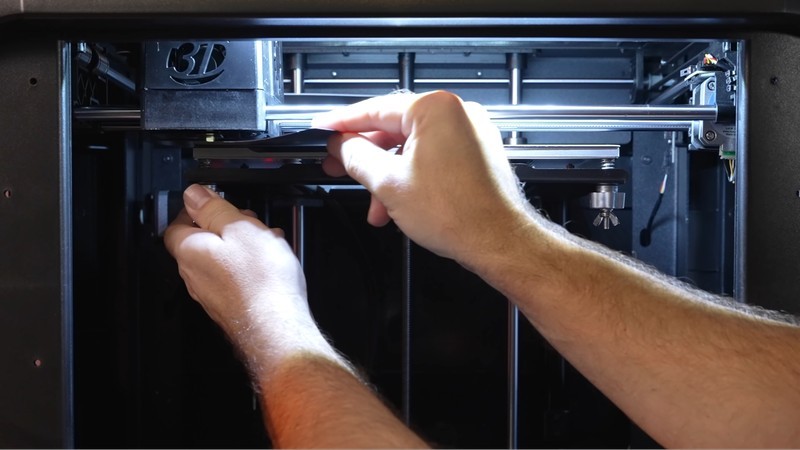

Credit: Design Prototype Test / YouTube

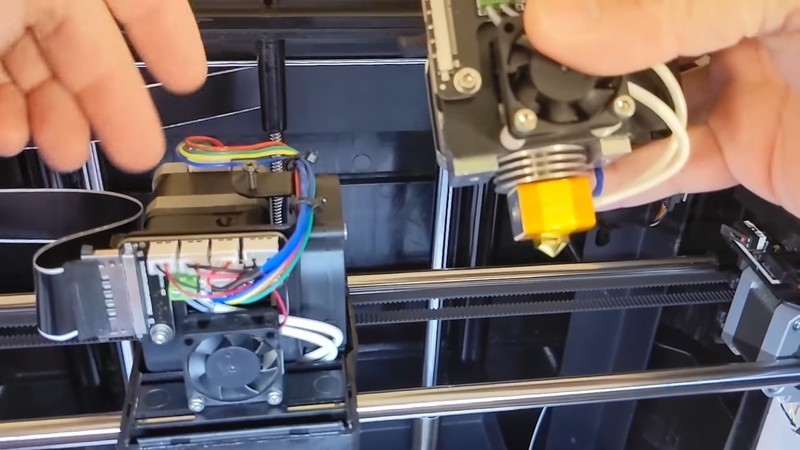

There’s also a direct drive extruder with a nozzle that can heat up to 250℃, which makes it compatible with most of the 3D printing filaments available on the market. The stock nozzle diameter is 0.4 mm, which is optimal for beginners and general-purpose prints. The supply package also contains a spare nozzle with a diameter of 0.2 mm, so you can try it right away and won’t have to order a new one and wait for it to be delivered.

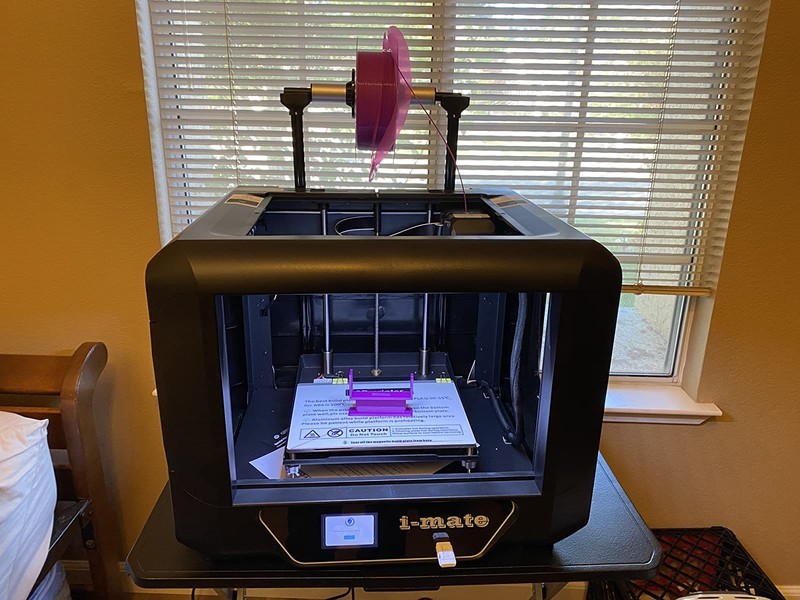

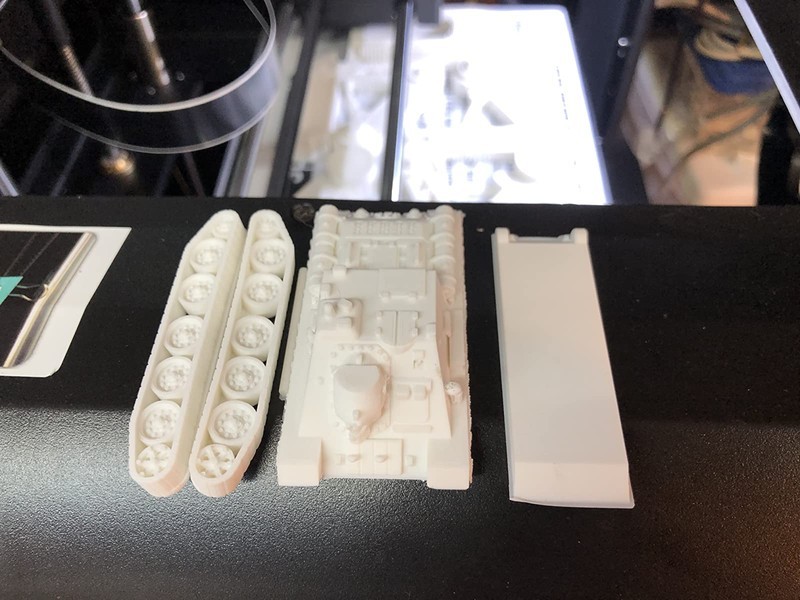

Credit: Jeff Thawley

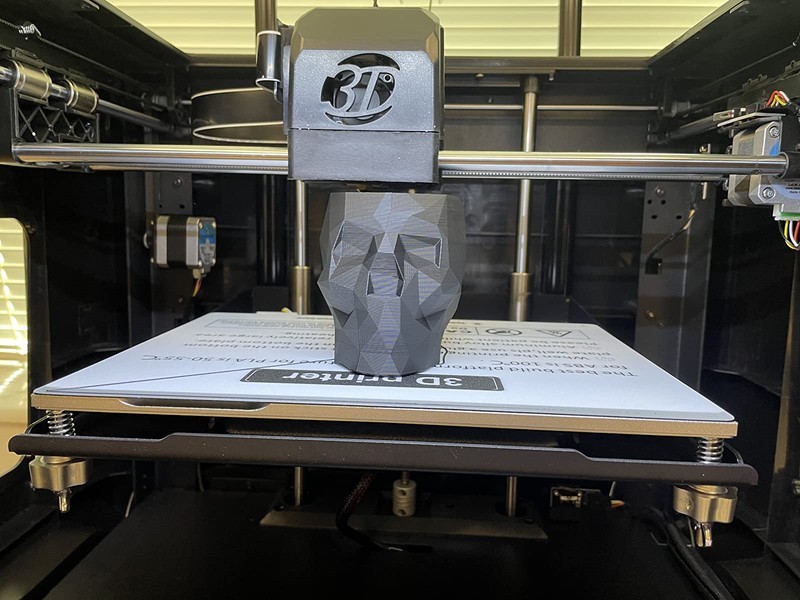

The QIDI Tech i-Mate is an entry-level FDM 3D printer that can print with PLA, PETG, and TPU filaments with a diameter of 1.75 mm. The i-Mate is an affordable and reliable machine that boasts its consistency alongside streamlined and integrated workflow. It offers just enough build volume to bring most of the ideas of 3D printing enthusiasts to life. Besides, the printer comes in a fully assembled state so it can be used shortly after unboxing.

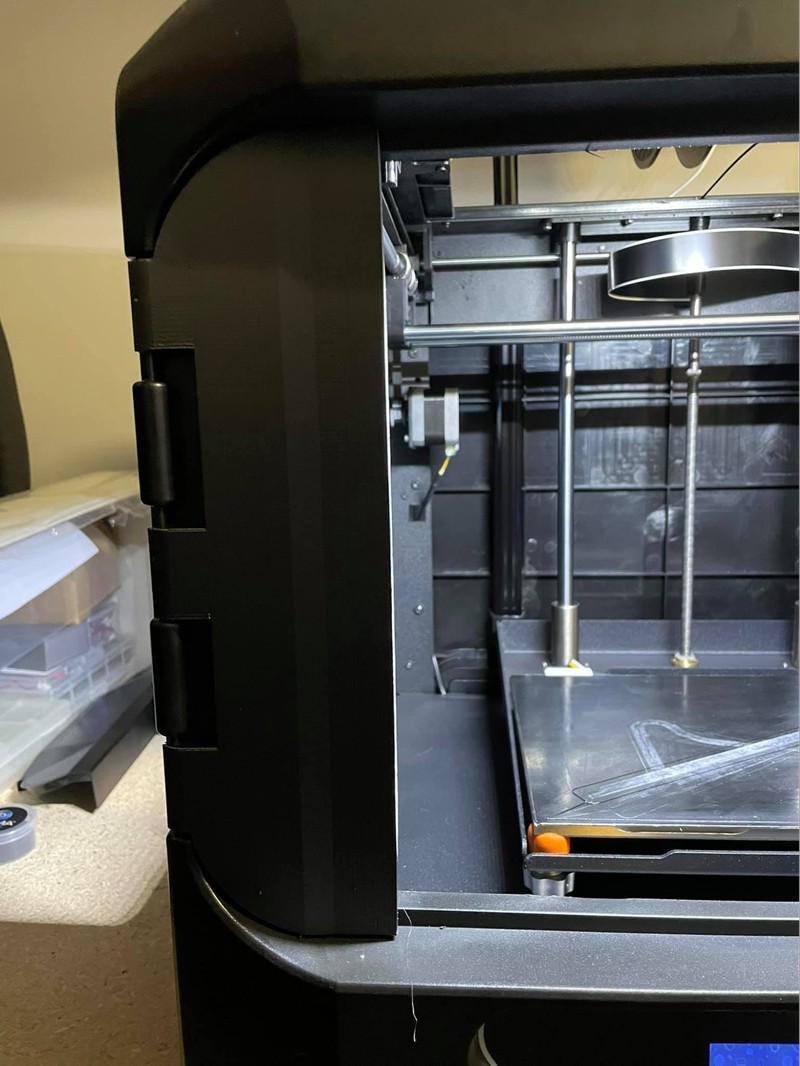

Credit: Chris

The enclosure helps keep hot and dangerous parts of the printer out of reach, so the QIDI i-Mate can even be employed in educational institutions as long as you restrict the access to the build chamber by enclosing the top cover completely. It is a plug-and-play device with Wi-Fi connectivity that can be controlled in an intuitive and straightforward manner, making it perfect for entry-level 3D printing enthusiasts.

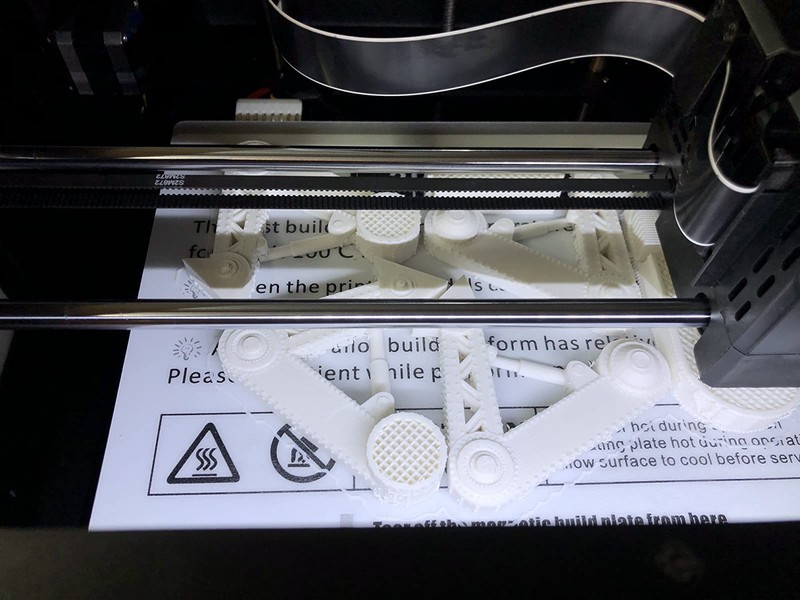

Credit: Chris

All things considered, the QIDI Tech i-Mate would be a perfect device for the production of precise and uniquely designed household items, props, toys, accessories, and dimensionally accurate prototypes.

Credit: Eric Shen

As you can see, the QIDI Tech i-Mate is a medium-sized 3D printer that boasts its smooth angles and futuristic outlook. It comes in a classic black color scheme and weighs 20.3 kg (44.7 lbs), which makes it a pretty heavy one. Consider asking your friends to help you do the lifting. Its outer dimensions are 560 x 450 x 420 mm (22 x 17.7 x 16.5 inches), which is typical for a medium-sized FDM 3D printer. The spool holder is mounted on the back of the machine.

The print head runs on rods with linear bearings. The body of the printer is represented by a sturdily built all-metal frame that makes printing consistent and precise by preventing any unwanted vibrations that can mess up your entire print. Indeed, the i-Mate is built like a tank, and it’s a good thing that it doesn’t weigh like one. The clamping shaft couplers help transfer the rotational motion as intended. Paired with reliable eccentric nuts, the printer works as intended with minimum to none wobbling-related issues.

Credit: Chevy Christian

The door hinge design is pretty responsive and you won’t likely encounter any issues with the print chamber access. On the other hand, the printer design could’ve been made a whole lot safer if there was a sensor to automatically stop printing and lock the door until the build platform and the nozzle had cooled down completely.

Credit: Correena Christian

The fact that the QIDI i-Mate is equipped with a semi-enclosed body does not surprise us at all, because producing entry-level FDM 3D printers with partial enclosure has been a trend lately. In our opinion, this was done not only to make the i-Mate more affordable but also to increase the price tag of its older brother — the i-Mate S — by $100 and sell it to makers that don’t really want to tinker with upgrades and want to print hard-to-break ABS-based parts right away. Still, the design of the i-Mate is considerably safer than that of its open-frame counterparts and it performs really well when working with PLA.

The QIDI i-Mate is equipped with a high-end power supply that can adapt to different voltages and withstand power surges, making this well-built device a whole lot safer. It can work in 110/220V mode and will prove particularly useful for people living in areas with unreliable grid supply.

Credit: Design Prototype Test / YouTube

The i-Mate is powered by a high-end mainboard that is equipped with the noise-free TMC2209 stepper motor driver chip. It makes the whole assembly operate at 50 dB or less, which is essential for daily and nocturnal printing sessions.

Last but not least, the QIDI Tech i-Mate has a built-in Wi-Fi module that lets you control the printer remotely. Indeed, it is a very nice addition for a printer that comes at a sub-$350 price tag that is rarely seen on such budget-friendly machines.

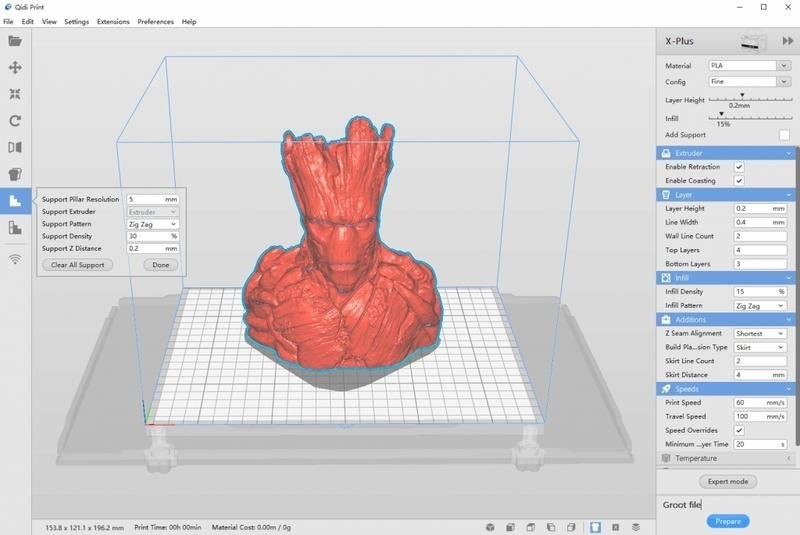

The printer is recommended to be used with QIDI Print slicer, a self-developed and user-friendly software solution. It is based on the popular Cura Slicer and provides most of the features of its counterpart. The software has a pre-made printing profile with optimal settings for general-purpose prints available right away, so you can dive headfirst into the 3D printing shortly after unboxing the printer and setting it up. Just drag and drop the 3D model you’d like to shape into the software window to begin printing. Don’t worry if you aren’t proficient in 3D modeling, because you can find a wide range of unique and free 3D models to print on Thingiverse and other related websites.

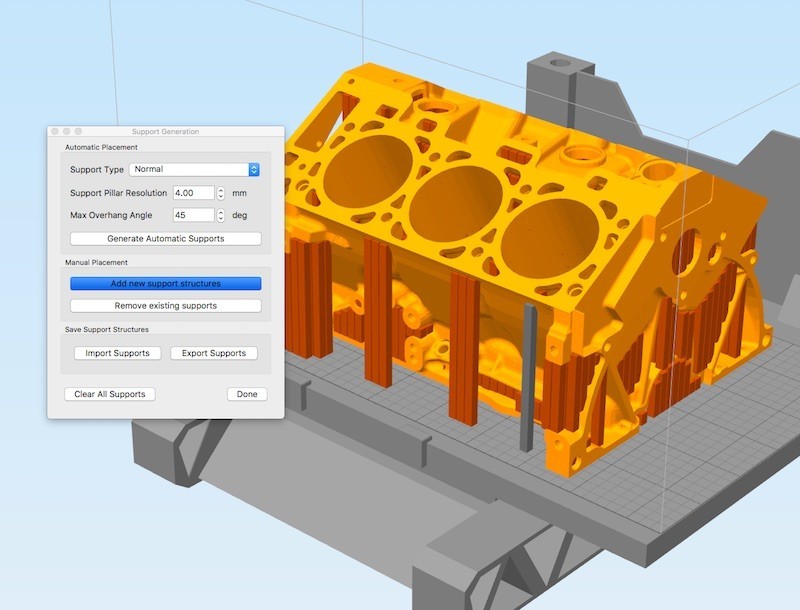

Source: simplify3d.com

Simplify3D is yet another software suite that the QIDI Tech i-Mate can run on. It lets you switch between multiple printers and run pre-print simulations to detect design flaws in advance. Besides, the supports can be built automatically as well as customized manually. The software lets you tinker with a plethora of professional tools and advanced options to fine-tune the machine.

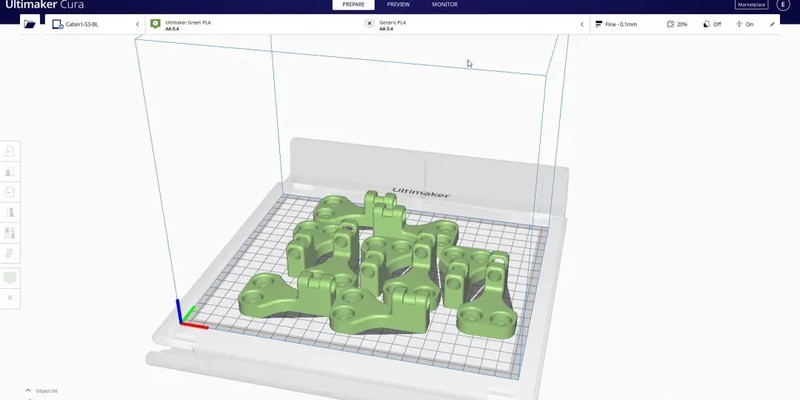

Source: ultimaker.com

But wait, there’s more! You can also use the Ultimaker Cura itself as your slicing software solution. It is a swift and easy-to-use slicer that guarantees optimal performance when used with FDM 3D printers. This trusted and time-checked software suite lets you rotate, edit, one-click print your models, build supports, and tinker with other print settings to fine-tune the machine. You can click here to check out our review of the slicer.

For some items, package content may change. In case of any questions, please get in touch.

The QIDI Tech i-Mate comes in a fully assembled state, so all you have to do in order to begin printing is to connect it to a power source and complete the bed leveling.

Credit: Just Vlad / YouTube

Select the ‘Leveling” option in the touchscreen interface. The build plate will move upwards until it meets the nozzle.

Credit: Just Vlad / YouTube

Then, take the leveling paper and place it between the nozzle and the build plate. Rotate the leveling knob located underneath the build plate to adjust the position until the piece of paper can barely move. Repeat the procedure for each remaining axis to complete the calibration.

Credit: Just Vlad / YouTube

Credit: Just Vlad / YouTube

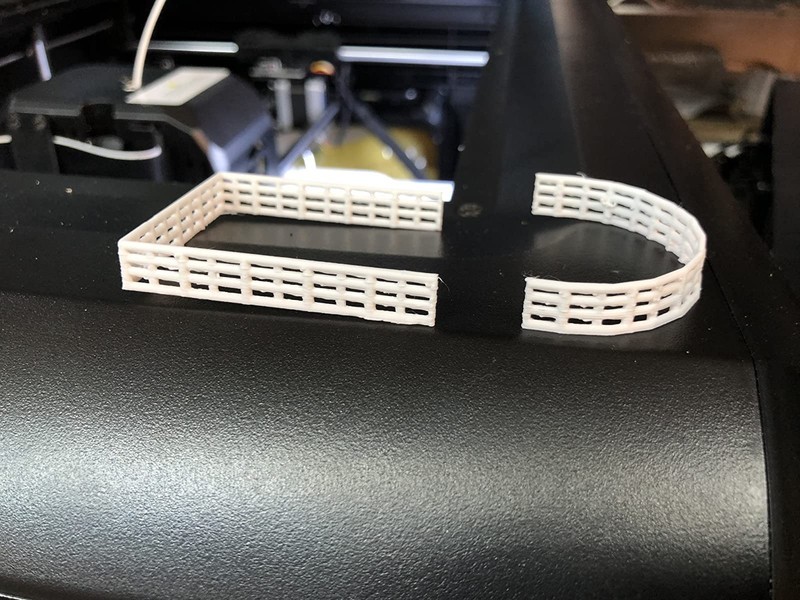

In case you’d like to reliably print with ABS and create hard-to-break items and prototypes, make sure to upgrade the i-Mate with an enclosure. A fully enclosed build chamber helps to maintain optimal temperature conditions required to print with high-temperature plastics, prevents unwanted temperature fluctuations, misprints on upper layers, and makes the assembly considerably safer. You can make the enclosure yourself or order it online. There’s also an option of purchasing the i-Mate S because it comes with a fully enclosed build chamber right away. All things considered, upgrading the i-Mate yourself will be cheaper than purchasing the i-Mate S and paying $100 more for a simple plastic enclosure.

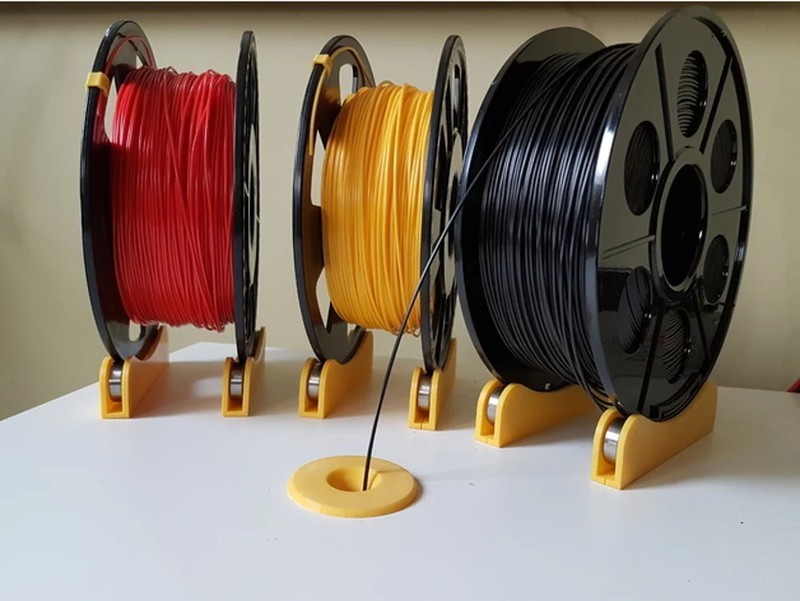

Credit: filamentry / Thingiverse

A new spool holder is a good mod for makers that want to enhance their 3D printing experience or simply looking for a change of pace. The main advantage of TUSH spool holders shown in the image above is that re-equipping a spool becomes a piece of cake. The best part comes from the fact that the spool holders are entirely 3D printable, so you can make it yourself. You will still need some 608 bearings to hold the spool in place though, but they are very cheap to come by.

Another essential upgrade is a BLTouch probe for automatic bed leveling. This will make the bed leveling process less time-consuming and much more precise.

Source: RepRap.me

Once the bed is leveled manually, the sensor will probe it and automatically re-calibrate if needed.

Credit: Edward Raub

Poor build plate adhesion is one of the most commonly encountered FDM 3D printing problems. The reason behind this is that the first layers don’t provide enough adhesion to hold the print in place. Try to increase the temperature of the heated bed or cover the platform with an adhesive (e.g. hairspray, glue stick, ABS juice, Kapton, or BuildTak coatings) to deal with the problem. You can also ensure better layer adhesion by increasing the area of the bottom layer that holds your print in place by creating a raft.

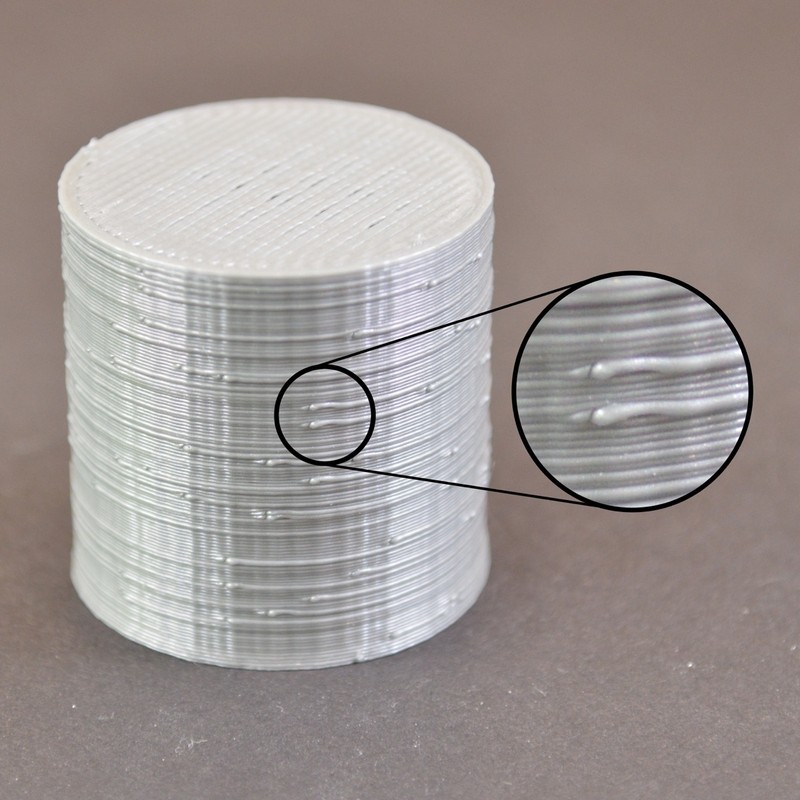

Source: simplify3d.com

Blobs (also called “Zits”) are small but numerous surface imperfections that can appear due to excessive extruder movement and over extrusion. There are numerous ways that can help you fix the issue. First of all, try to set all speeds (e.g. outer walls and infills) to the same value and enable retraction and coasting in the slicing software. Retraction is a particularly useful setting that ensures that the filament is pulled back into the extruder when the print head moves between the printing points. Make sure to adjust the retraction speed accordingly, because blobs may still appear if the filament is not pulled back fast enough.

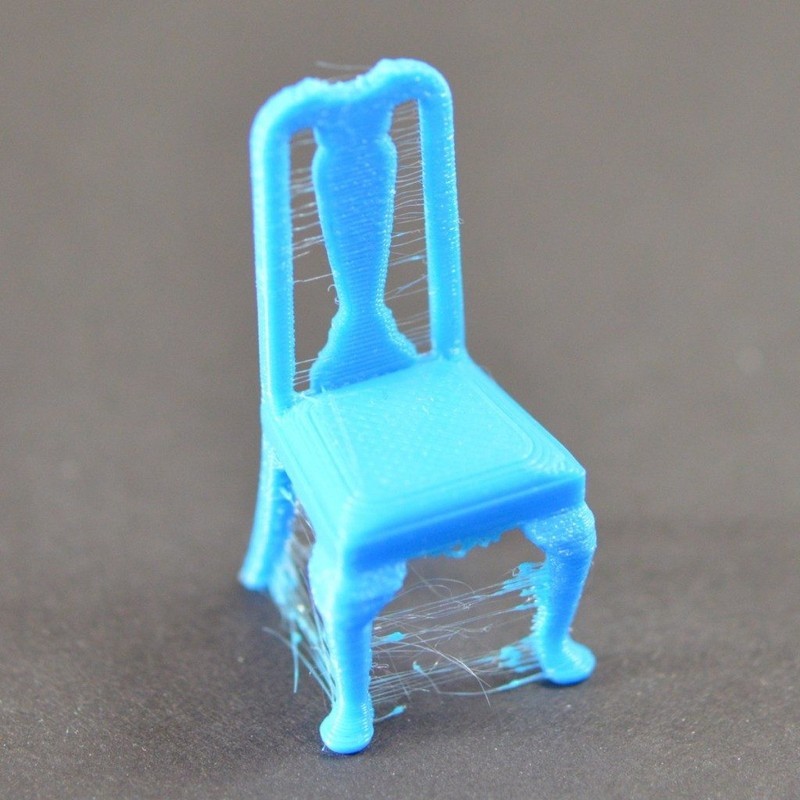

Source: simplify3d.com

Stringing is yet another common issue that appears on FFF/FDM-powered machines. This tends to happen when you set the extruder temperature too high, which makes melting plastic too liquid and it flows out of the nozzle, enforcing the appearance of thin strings in places where the printer was not even supposed to print.

Lower the extruder temperature and activate retraction in your slicer settings to solve the problem.

Credit: Jeff Thawley

Credit: Correena Christian

Credit: Correena Christian

Credit: Reginald Brown

Pros

Cons

All in all, the QIDI Tech i-Mate is a finely designed and sturdily built entry-level FDM 3D printer that can print with a wide array of 3D printable filaments. It comes at a tempting price tag and offers a built-in Wi-Fi module, magnetic heat bed, and a single direct drive extruder. Besides, it ships in a fully assembled state, so it can work shortly after you unbox it and complete the calibration. You can use the QIDI Tech i-Mate to print toys, props, uniquely designed household items, tabletop figurines and miniatures, cosplay accessories, prototypes, and much more.

The QIDI Tech i-Mate can be purchased at Top 3D Shop. This affordable FDM 3D printer comes with the manufacturer’s warranty. Besides, our team will make sure to provide the best service possible, just like we always do.

Update your browser to view this website correctly. Update my browser now

Write a comment