In recent years, the retail 3D printer market seems to offer more and more models that use LCD technology. Ironic as it is, this step is basically a return to origins, because the first 3D printer was based on SLA technology (that is, the same principle of photopolymerization). The major differences of modern devices from the pioneer in this area are affordability, ease of operation, and improved print quality. This is why many companies began to produce home resin 3D printers. One of the first such devices is the Anycubic Photon Mono, which greatly impressed users with its excellent quality and high print speed. Read on to learn more.

Despite its modest appearance, the Anycubic Photon Mono offers rather good performance. Although it cannot boast a large print area, this model is characterized by a high print speed. A UV wavelength of 405 nm allows working with most of the resins available. The device uses a USB connector instead of MiniSD and MicroSD cards. The relatively small power supply unit will not take up much space. Now, let's look at the specs, supply package, and main elements of the 3D printer.

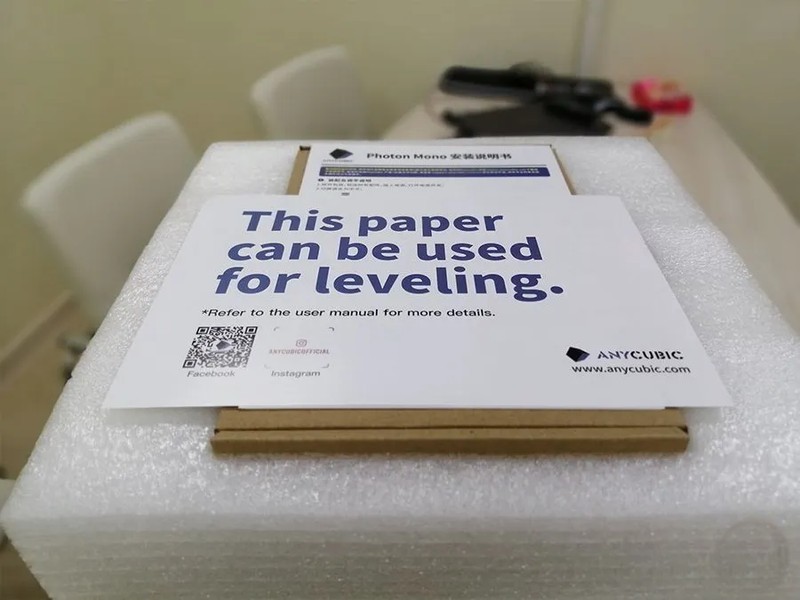

Like any Anycubic product, this model comes in a well-protected box. Having opened it, we can see a sheet of paper (which is subsequently used to level the print bed), a user manual, and a box with additional items.

The box includes:

The flash drive contains all the necessary information you need to get started.

Removing the top of the package reveals a yellow protective lid packed in a thick film.

Under the lid, there are two remaining parts: the bed and the vat. The assembly consists in attaching the bed to the printer and calibrating it.

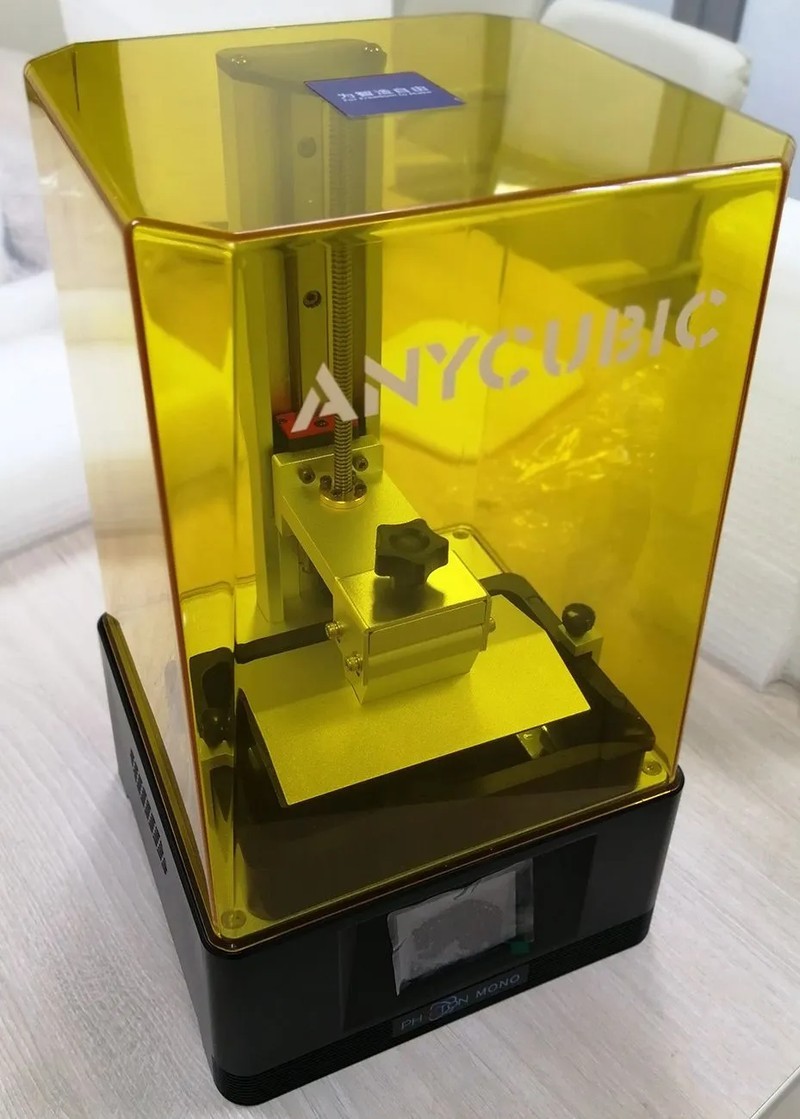

Unlike early home resin printers, the Anycubic Photon Mono has an all-metal structure, the only exceptions being the vat and the lid. Besides, the lid is coated with ultraviolet filtering. This allows a safe look at the printing process. There is also a mechanism for checking the position of the lid in the form of a sticker on its back. This further enhances safety during the printing process. On the same side of the main body, there are holes for the ventilation of electronics and a power connector.

The left side contains a power switch and a USB connector.

On the front is a recessed touch screen at a slight angle, which increases the convenience of use and prevents damage to it.

The mechanics are also made of metal. One motor and a trapezoidal rod are used to move the print bed. The plate itself moves along the rail, increasing the accuracy and reliability.

A simple optical sensor is used as the limit switch, where a thin steel plate serves as an obstacle in the path of light.

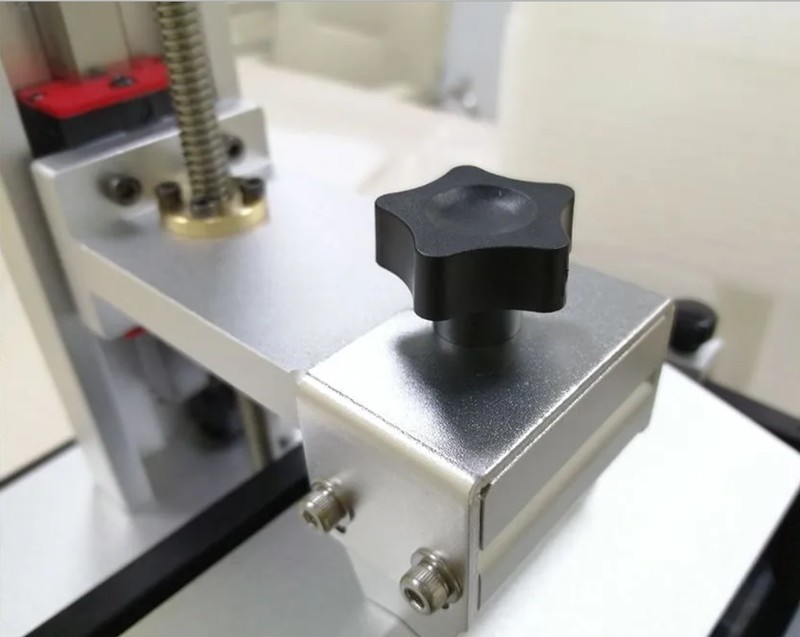

The bed is fastened to the Z-axis with one clamping screw knob, and its adjustment is provided by four screws on both sides of the bracket pressed by the previously mentioned clamping screw.

The matrix resolution in this model is 2560 x 1620 pixels or 2K. This pixel density allows for stunning quality comparable to industrial production by casting or injection molding.

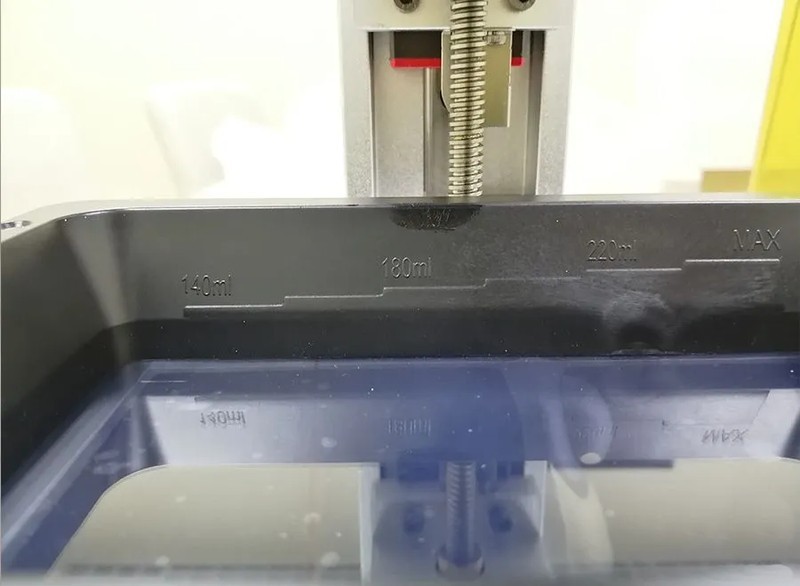

The frame of the vat is made of heavy-duty plastic that is resistant to photopolymer. In one of the corners, there is a cutout for easy drainage of polymer residues. The vat is fixed to the base with two screws pressing it to the screen, thereby completely eliminating the possibility of a gap between the film and the matrix.

Another good feature is scale marks on one of the vat sides indicating the remaining amount of resin in the vat.

Thanks to its high print quality, the Anycubic Photon Mono is used where manual precision or FDM technology is not enough. For example, in jewelry: first, a model is printed, then it is placed in a plaster mold if the printout is from a burnable polymer or in a silicone one if it is from model plastic, after which metal is poured into the mold through special channels. The jeweler removes the excess metal at the place of pouring and polishes the resulting workpiece. In some cases, for the manufacture of special jewelry, only with the help of resin 3D printers can the required accuracy and unusual shape be achieved.

Jewelry made by casting into a printed model

Resin 3D printers are also used for the production of character figurines. The big advantage of SLA technology is the ability to print "hanging" elements, which greatly simplifies the post-processing of a model.

Figurine printed on the Anycubic Photon Mono without post-processing

Unlike FDM devices, printers that use LCD technology create models with no obvious texture. Only on closer inspection can you notice the “pixelated” relief, which can be easily removed with manual processing, a sandblaster, or using a thin layer of primer. For instance, the following model was processed using the latter method.

And in the next photo is a model without any post-processing.

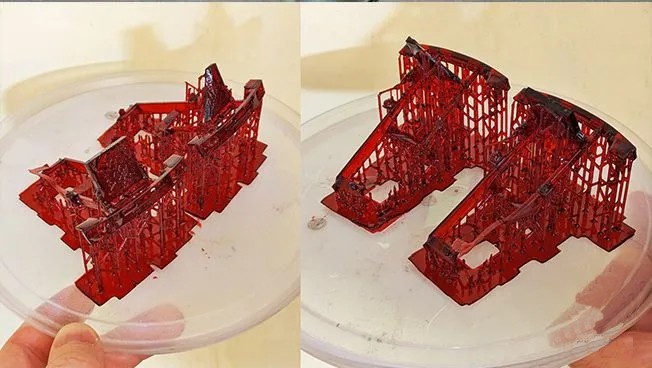

With the help of transparent resins, you can get the "magic crystal" effect.

Despite its affordability, the Anycubic Photon Mono offers high print quality, great reliability, and wide application opportunities. Safety is ensured not only by passive methods such as a protective lid with an ultraviolet filter but also by some active ones (monitoring the position of the lid). In addition to these advantages, the device features a simple design that facilitates maintenance and repair. Last but not least, due to the great popularity of this model both in business and among hobbyists, you can easily find a large number of instructions and tips for it on the Internet.

Update your browser to view this website correctly. Update my browser now

Write a comment