We recently supplied a Shining3D iSLA-450 Pro 3D printer to a manufacturing facility that specializes in low-voltage equipment, automation, control, and information security systems for marine applications. Their systems help ensure safe and efficient navigation for vessels worldwide.

The iSLA-450 Pro is an industrial SLA system designed for accurate, stable production of functional parts and tooling from photopolymer resins.

Print technology: SLA

Laser spot resolution: 0.1–0.15 mm

Laser wavelength: 355 nm

Print material: photopolymer resin

Build volume: 450 × 450 × 400 mm

Layer resolution: 50 μm

Print accuracy: ±0.05 mm (up to 100 mm), ±0.1% (over 100 mm)

Print speed: 10 g/h

Supported file formats: .stl, .slc

Power supply: 220 V, 50 Hz

Power consumption: 2000 W

OS support: Windows XP, Windows 7

Dimensions: 1100 × 1400 × 1800 mm

Previously, the factory designed and produced enclosures and structural parts using traditional manual prototype fabrication and testing. This approach took a lot of time and increased development costs.

By introducing digital manufacturing and 3D printing, the plant can now produce prototype parts and tooling much faster and at a lower cost, which shortens development cycles for new equipment.

The client designs and manufactures equipment and control systems for seagoing vessels of all classes. To solve several production challenges, the factory decided to bring additive manufacturing into its workflow.

Their first point of contact was Top3DShop. The brief: select and supply a 3D printer capable of producing molds for a vertical injection molding machine.

After evaluating options, the client chose the industrial Shining3D iSLA-450 SLA printer as the best fit for accuracy, build volume, and material flexibility.

A key advantage of the iSLA-450 is its ability to work with almost any compatible photopolymer resin on the market. The customer selected Somos PerFORM because of its high temperature resistance — printed parts can withstand up to 268 °C, which makes the material suitable for injection mold inserts.

Somos PerFORM properties:

By switching to digital manufacturing, the factory gains significant time and cost savings on short runs of plastic parts compared to traditional mold-making workflows. Instead of milling every mold on a CNC machine, they now 3D print injection molds for their vertical press:

Mold production becomes considerably cheaper and faster.

Each 3D-printed mold works for about 200 castings without noticeable loss of quality, which is ideal for small batches and custom parts.

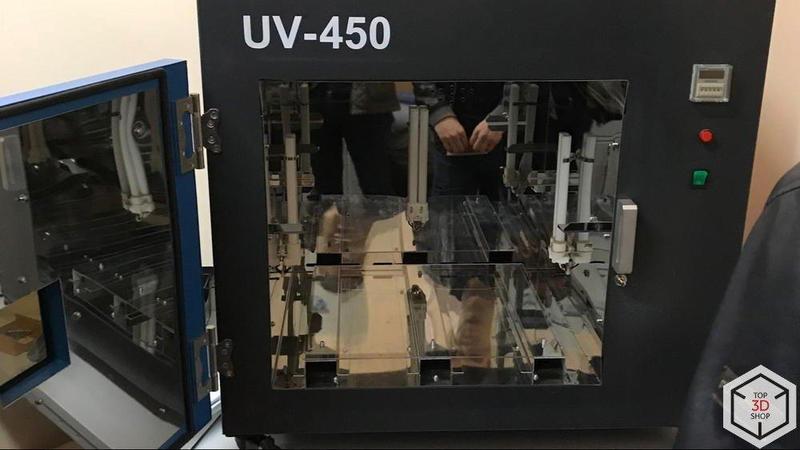

We delivered and installed the iSLA-450 along with all required auxiliary equipment:

A washing chamber

A ProJet Finisher oven for thermal post-curing

A UV curing chamber

After placing and leveling the printer, we:

Calibrated the laser system and build platform

Adjusted the wiper blade and resin detector levels

Handed over all user manuals and documentation to the engineers

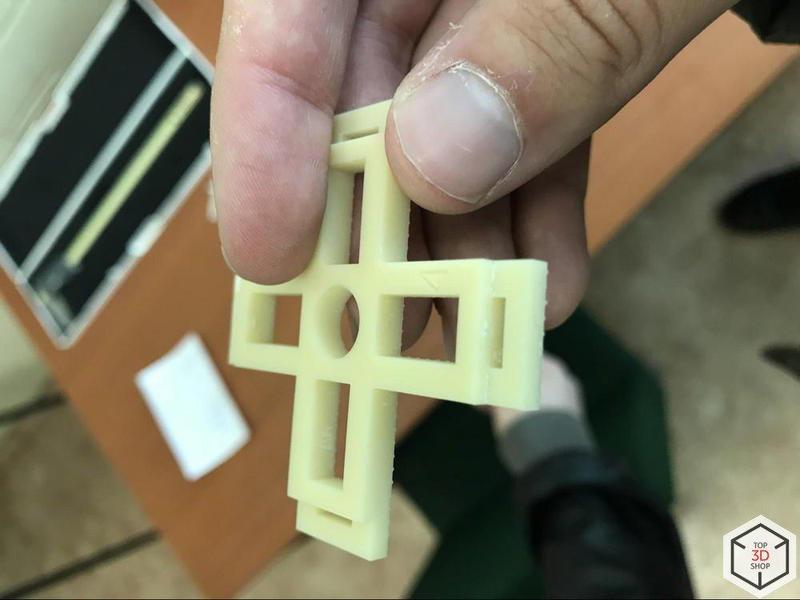

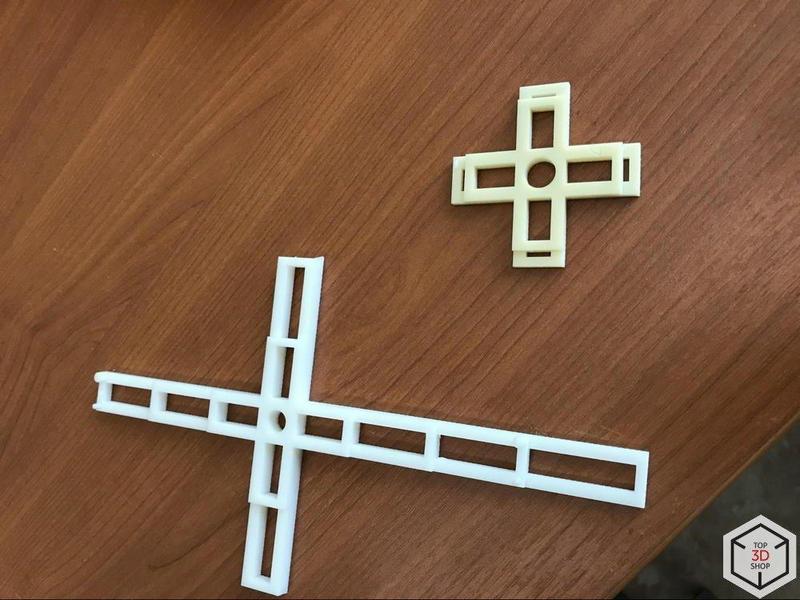

We then ran a test build, cleaned it in the washing chamber, and baked it in the oven to verify curing and material behavior.

The Shining3D iSLA-450 worked very well with Somos PerFORM. The resulting test mold will be tested in the vertical injection molding machine under real operating conditions.

The photo from the project shows a calibration test piece that lets us verify correct geometry, tolerances, and accuracy along all axes.

An industrial solution at this level starts at around $100,000, which is justified for small-scale and short-run manufacturing when you compare it to the time and cost of CNC mold production.

3D printing already has a solid place in manufacturing. It does not replace every process, but it gives clear advantages in rapid prototyping and precise production of one-off and short-run components with durability comparable to traditionally made parts.

Contact Top3DShop to find out how we can help you modernize your production processes with industrial 3D printers.

Update your browser to view this website correctly. Update my browser now

Write a comment