The model only defined external geometry and textures, so we couldn’t print it as-is.

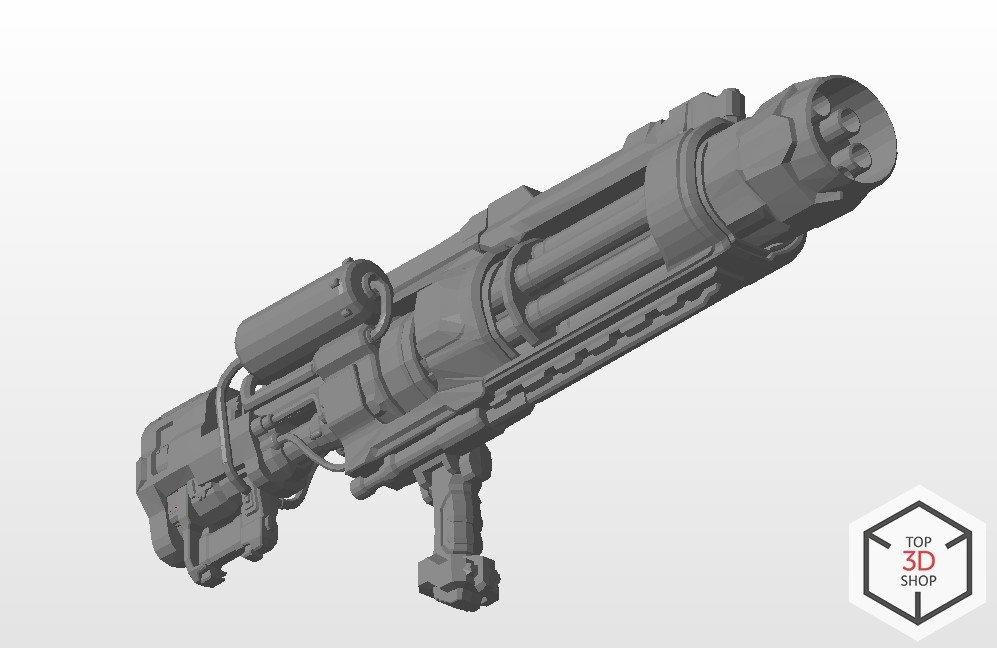

The developers of Marsenary, an online first-person multiplayer shooter, asked us to build a 1.5-meter replica of their minigun-style weapon as a prop for their booth at the Electronic Entertainment Expo (E3) in Los Angeles.

The minigun

The E3 exhibition in LA

In Marsenary, the multibarreled machine gun is the default weapon of the Juggernaut class — heavily armored exoskeleton mercenaries fighting in a war between mining corporations on Mars.

The game mixes first-person shooting with strategy: players build, defend, and capture other players’ mining bases, called forts.

Studios used to order such props from theatrical or special effects shops. Builds often turned out inaccurate, slow to deliver, and expensive.

Makers commonly used papier-mâché, plastic, cardboard, plywood, and sometimes even paper for imitation weapons.

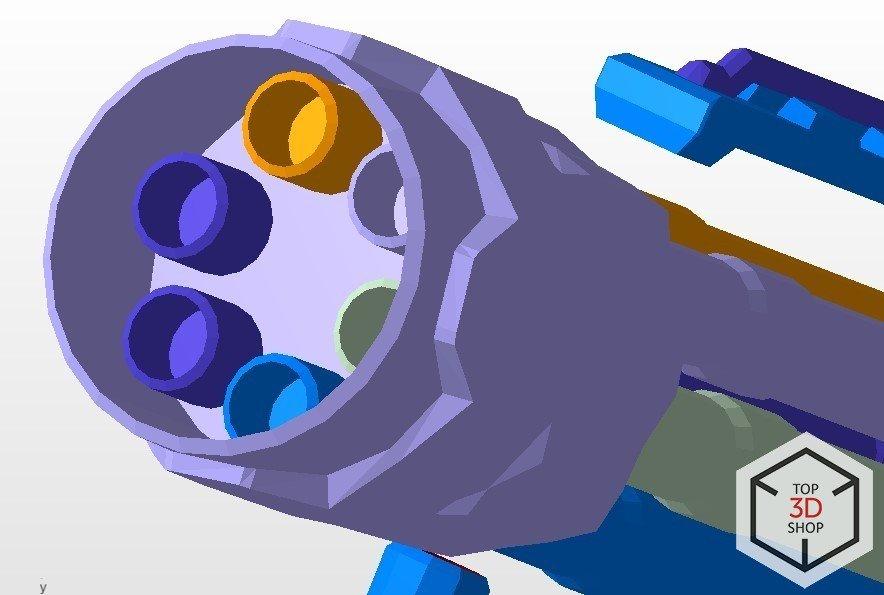

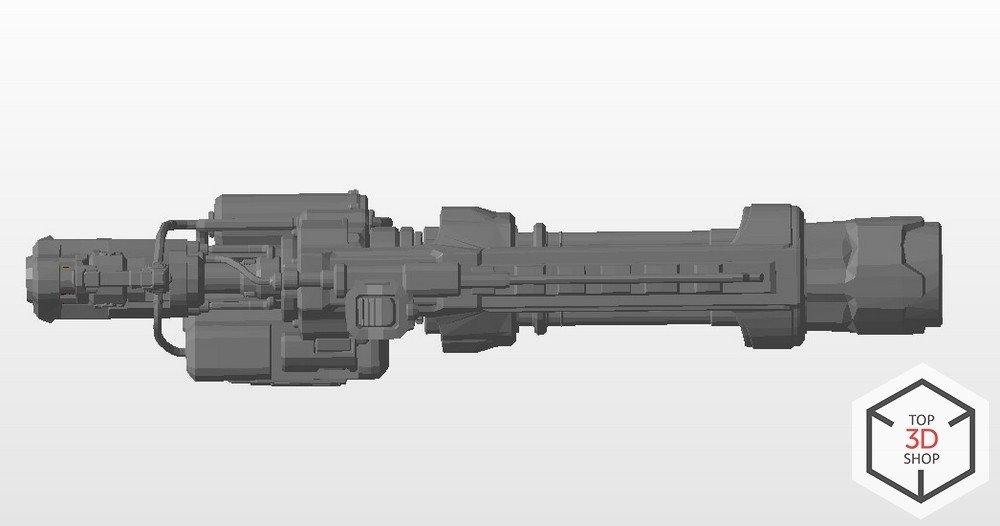

The customer provided us with a 3D model in .obj format, the kind used for in-game visualizations, and some colored renders as guidance for painting.

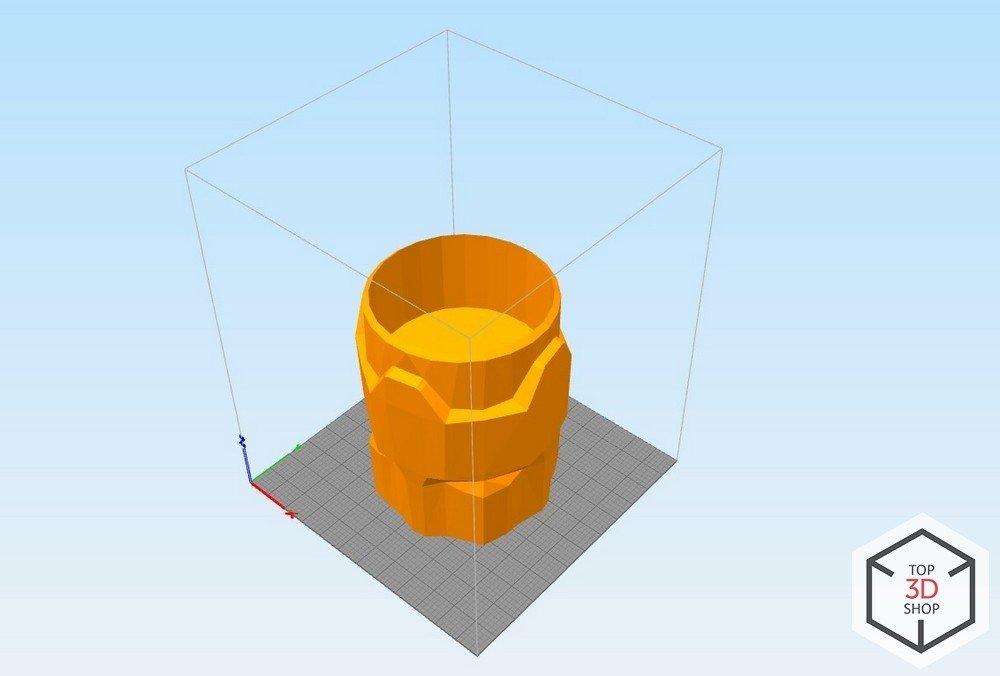

The model only defined external geometry and textures, so we couldn’t print it as-is.

Low-poly angles and chunky polygons disappear in fast gameplay, but they stand out on a physical model you can hold. The developers’ artwork shows the gun with smooth, rounded edges and surfaces.

We rebuilt the model by adding inner volume, closing open polygons, increasing mesh resolution, and detailing all 25 components.

A 3D designer spent 15 hours on this touch-up. The model now looked smoother, less angular, and more natural.

Preparing and printing

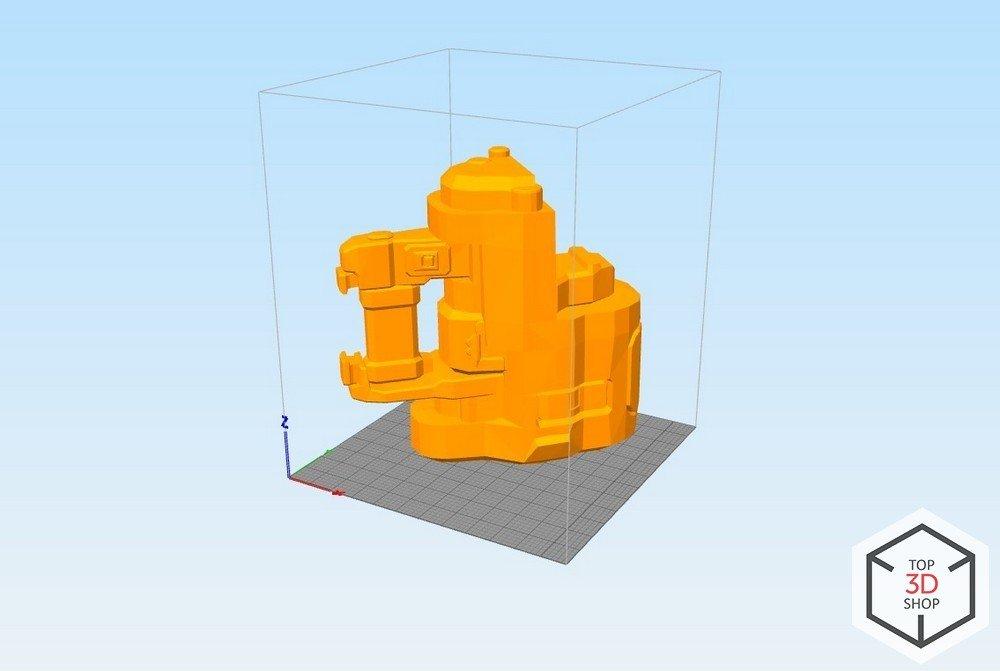

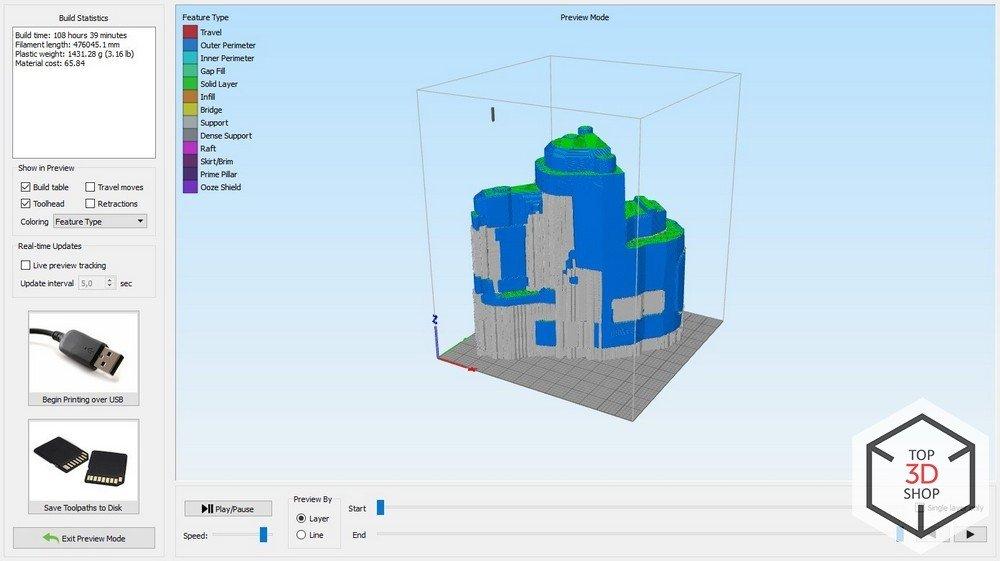

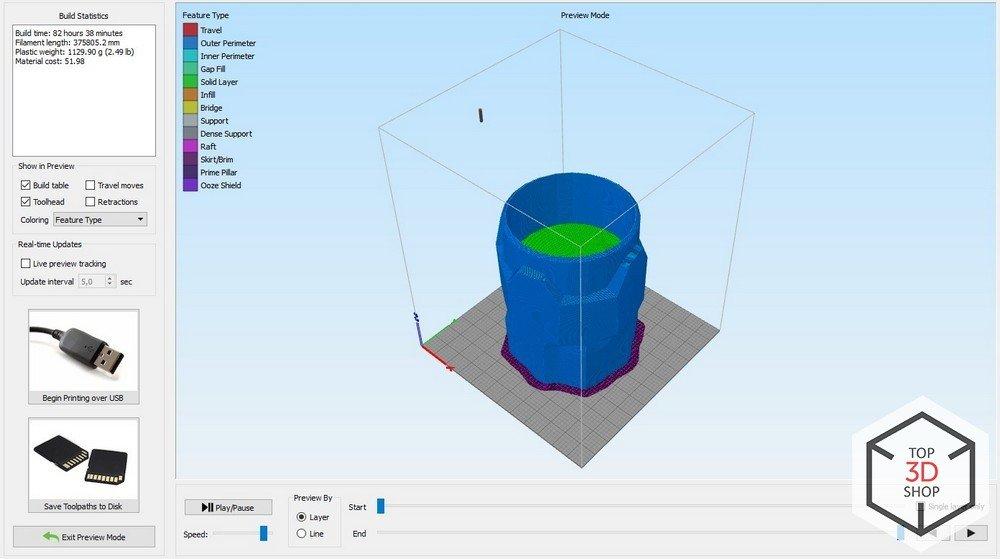

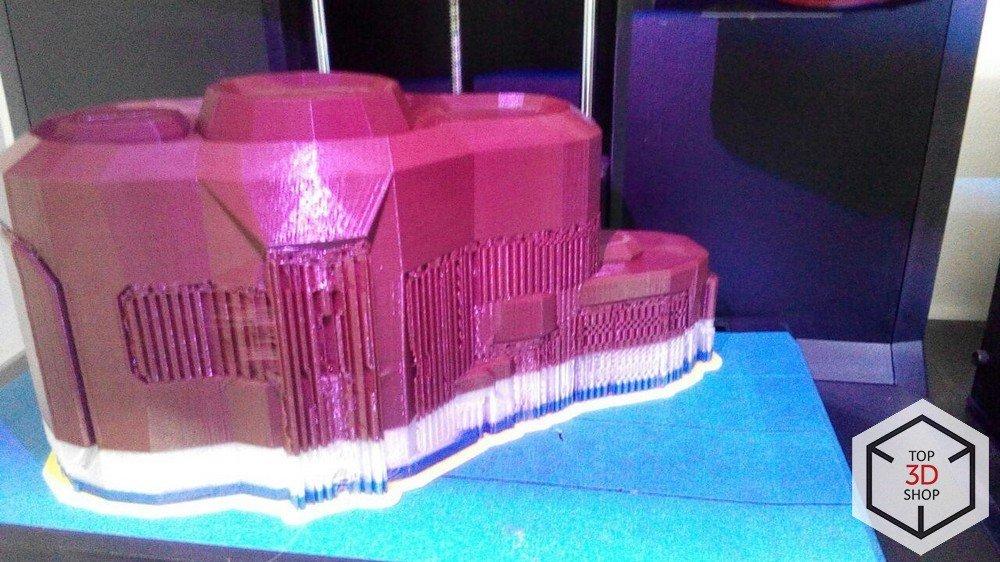

The 1.5-meter length exceeded a single print chamber, so we sliced the model into sections and printed them separately.

We used PLA and ABS in different colors to simplify assembly and keep track of parts.

Key print details:

Largest part: 422 mm high, fully filling the MakerBot Replicator Z18 chamber

Other parts: up to 300 × 300 × 160 mm and 220 × 200 × 100 mm

Total printed volume: ~43,000 cm³

Assembly and finishing

After printing, we assembled all sections into the full 1.5-meter minigun.

Try hauling that around without an exoskeleton.

Then we were ready to paint it.

It turned out just like the one in the game.

The customer collected the finished model and sent it to the conference in Los Angeles.

To speed up production, we printed different parts on several machines at once.

Top3DShop sells large-format 3D printers to build parts up to 1.8 meter in size. Contact us today, and find the best equipment for your project.

Update your browser to view this website correctly. Update my browser now

Write a comment