Nowadays, professional-level FDM 3D printing is more affordable than it's ever been. It’s possible to get a multi-purpose beginner-friendly machine with an impressive set of features, sizable build volume, and ease of use without paying a fortune or having to sacrifice print quality.

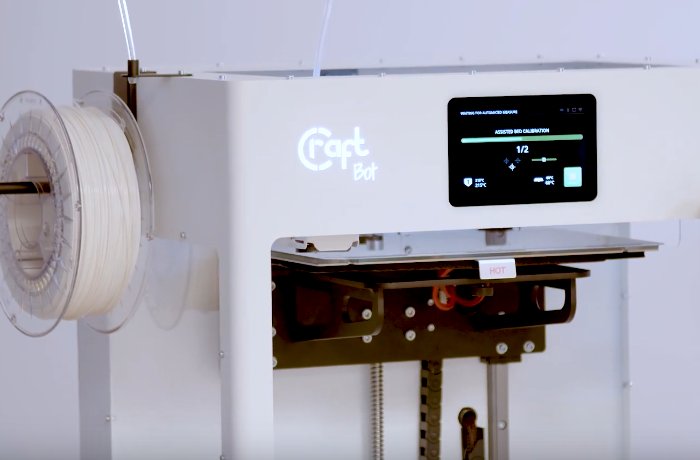

Hungarian manufacturer CraftBot offers one of such solutions: a professional single extrusion FDM 3D Printer named CraftBot Flow. It has all of the features expected from a modern professional FDM 3D printer without sacrificing being easy to set up and work with.

Source: craftbot.com

CraftBot (formerly known as CraftUnique) is a 3D printer manufacturer and software developer, with plants in Hungary and offices in the US. The company was founded in 2014 and its first success was a crowdfunding campaign for the CraftBot 3D printer on Indiegogo. Since then the company has grown to be a successful brand in the world of additive manufacturing.

The CraftBot Flow is a device of the Flow generation of 3D printers that also includes a larger-volume version named CraftBot Flow XL and two dual-extrusion solutions: the Craftbot Flow IDEX and IDEX X. The Flow is the most basic machine of the series and was inspired by the previous successes of the brand: the CraftBot 3 and CraftBot PLUS.

The CraftBot Flow is a single extrusion 3D printer with an enclosed design. The machine features a relatively large build volume of 300 x 200 x 250 mm and comes fully assembled and ready to print right out of the box.

The CraftBot Flow features an assisted calibration feature. The semi-automatic process will guide you through all the steps required. Since the CraftBot Flow utilizes a motherboard based on a Raspberry Pi, its smart features are rather impressive: there’s 4GB of internal storage, wireless connectivity, web interface and a built-in camera for simple monitoring.

Source: youtube.com

The list of smart features doesn’t end here: there’s a print resume function and a uniquely designed bed (it’s multilayered and consists of 2 parts: a flexible part and a solid part, both improve adhesion and simplifying the print removal process). The filament monitoring system minimizes the chances of blockage and makes extrusion smoother. The machine’s enclosed design and high maximum temperature of its hot end allow the CraftBot Flow to work with a wide range of materials.

The results produced by the device are rather impressive. It shouldn’t come as a surprise, since the CraftBot Flow can print layers at 50 microns with an XYZ accuracy of 12.5x12.5x5 microns. The machine can achieve such accuracy even at high speeds: up to 200 mm/s.

The CraftBot Flow comes fully assembled in a box that is easy to open. The contents of the packaging include:

The CraftBot Flow features an assisted semi-automatic calibration. If you want to level the bed, you need to go through a few steps (the machine will guide your way).

Go to Settings.

Source: youtube.com

Click the ‘Calibrate’ button.

Source: youtube.com

Then start the calibration wizard.

Source: youtube.com

It will ask you to do some things before going through the calibration process:

Check all the boxes after following the steps and proceed.

Source: youtube.com

The first thing that the machine will do is to check for the lowest point and measure the offset between the BL Touch sensor and the extruder itself.

Source: youtube.com

Then the CraftBot Flow will heat itself to its operating temperature and calibrate the touch sensor and the hot end.

The next step would be to level the bed. The machine will guide you and show which screws need to be turned on the front, back, left and right.

Source: youtube.com

Source: youtube.com

The device will double-check the results and ask you to manipulate a screw again (if needed).

The next step is mesh bed leveling. The machine’s sensors will measure the distances and double-check everything.

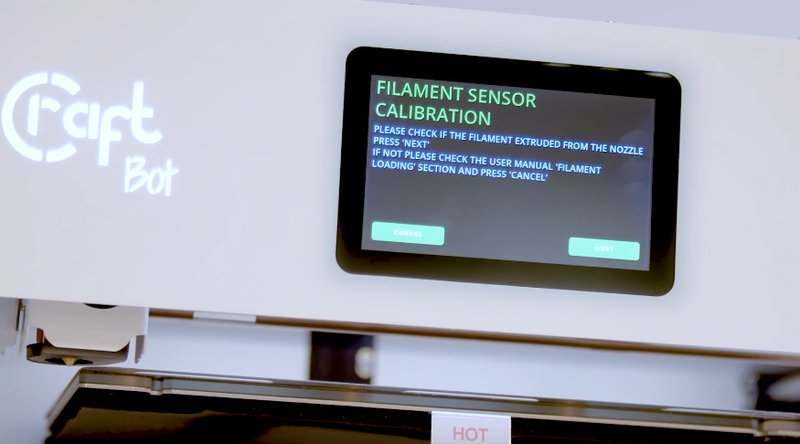

The last step of the process is a filament sensor calibration.

Source: youtube.com

First, you will go through the standard filament loading procedure. The machine will ask you to select the type of filament you’re planning to use. Then the device will heat itself and ask you to load the filament and click the ‘Load’ button.

Source: youtube.com

If the filament was extruded successfully, click the ‘Next’ button.

Source: youtube.com

Now the machine is ready to print.

The CraftBot Flow generation devices come with proprietary software named CrafWare (although it’s entirely possible to use these 3D printers with third-party solutions, including Cura). CraftWare has been compared to Simplify3D and utilizes a colorful and intuitive software.

Source: youtube.com

These nuts and screws prove that the CraftBot Flow is capable of producing high-precision fitting parts. They also look quite good.

Source: instagram.com

Source: instagram.com

Pros

Cons

The CraftBot Flow is a great multi-purpose professional FDM 3D printer. The machine supports various materials, features an enclosed design, provides many impressive smart abilities, and is easy to work with. Designed with simplicity in mind, the device nevertheless doesn’t compromise on its quality and size of its build volume.

The CraftBot Flow is a great choice for professionals and enthusiasts that value their time and want their printing to be as worry-free as possible while still getting high-quality results.

Update your browser to view this website correctly. Update my browser now

Write a comment