Competing with newly affordable resin 3D printers, FDM devices, in turn, had to offer something that would bring significant advances to the FFF technology. Among such is the dual extrusion system that allows simultaneously creating bicolor objects as well as support structures when printing models with complex geometry. Thus, one of the extruders prints with special soluble material which is consequently removed. This results not only in the print process becoming faster — the quality of models increases as well, owing to the improved accuracy. Apart from that, the dual extrusion technology enhances the reliability of equipment: should you have any trouble with one of the nozzles, the other can always be used to replace it.

This is Top 3D Shop, and in the following review, we will tell you about one of the best dual extruder 3D printers on the market — the CraftBot Flow IDEX by the renowned Hungarian manufacturer CraftUnique.

Specifications

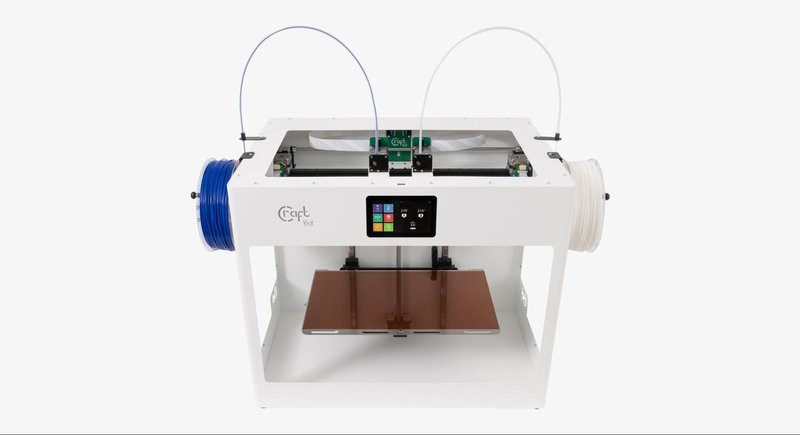

With its customers in mind, the CraftUnique company designed an outstanding lineup consisting of four devices: the single extrusion Flow 3D printer, its bigger version Flow XL, and two devices featuring dual extruders — the Flow IDEX and Flow IDEX XL. The models are based on the famous CraftBot 3 3D printer and boast some considerable improvements with due regard to users' reviews. To begin with, the product we are talking about today, the CraftBot Flow IDEX, is entirely made of reinforced steel to ensure better stability and reliability.

Source: craftbot.com

The printer also adopts brand new all-metal hotends and a powerful motherboard with a Raspberry engine to enable more flexible developments. It employs a layered flexible heated bed composed of metal, tempered glass, and Kapton to provide great adhesion and easy print removal. The pause-and-print function makes it possible to stop a print job and resume it at any time. Besides, this prevents failures in case of a sudden power outage. The built-in camera and LED status indicator allow for unattended 3D printing.

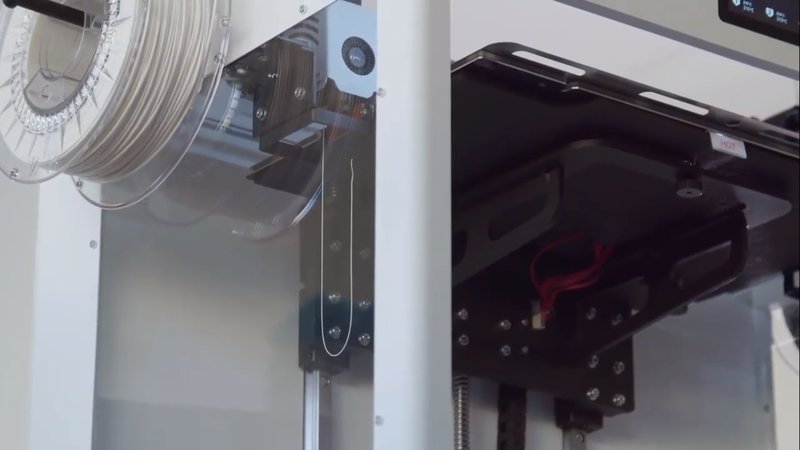

With the filament monitoring sensor, you can avoid any material problems or damage. The device boasts an independent dual extrusion system with two standard 0.4 mm nozzles to print multicolor and multi-material objects in mirror or parallel mode, doubling your productivity.

Source: craftbot.com

The 4GB internal storage for standalone operation and the large onboard color touchscreen with an intuitive interface add to the convenience of use. Thanks to the operating nozzle temperature of 300 °C and the metal hotends, you can print with a broad range of filaments including standard and specialty ones. The print heads move along linear rail guides ensuring fast, precise, and reliable printing.

Source: craftbot.com

The CraftBot Flow IDEX 3D printer is a great tool for small-scale production, industrial design, engineering, and rapid prototyping.

Apart from the printer itself, the package contains the following set of tools and accessories: a cleaning kit, two nozzle kits, five hex wrenches, two filament spools and holders, two filament guide tubes and holders, a flash drive and USB A-B cable, and AC power cord.

Source: craftbot.com

Inside the cleaning kit, you will find such accessories as nippers, a scraper, brush, and other useful items.

Source: youtube.com

The CraftBot Flow IDEX is a plug-and-play device that comes fully assembled. As is the case with most 3D printers, the only thing to be done before proceeding to print is calibrate the machine. The product in question features semi-automatic calibration, the full process of which is described below.

First, make sure there is no filament in the system and remove any objects from the print bed, cleaning it with alcohol using the wipes provided in the maintenance kit. Once these preparations are done, you can start the calibration process, which includes different options such as Manual Bed, Mesh Bed, Extruder, Offset. We will go with the Wizard option comprising all the necessary procedures to be performed before the printing process.

To get the printer ready for calibration, tap the Settings button on the LCD touchscreen and then the Calibrate button. Choosing the Wizard option, you will have to confirm that all the actions described in the previous paragraph are performed. If so, click on Next.

Source: youtube.com

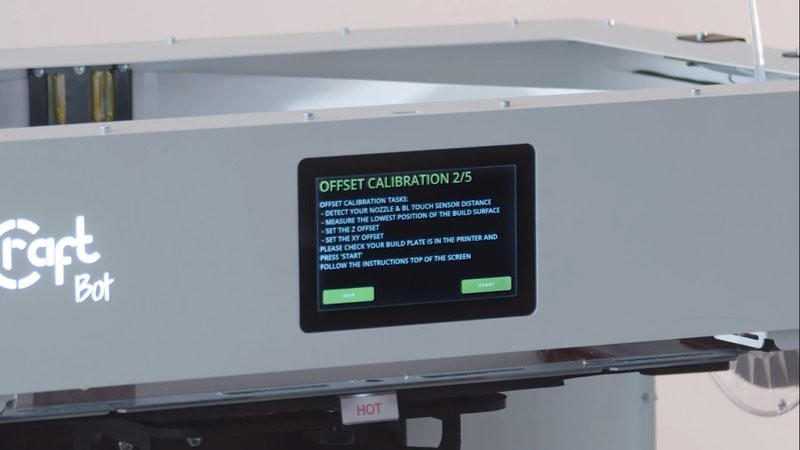

Then you’ll be informed about the offset calibration tasks which can be seen in the following picture.

Source: youtube.com

Most of the process will be performed automatically. When the Wizard has completed detecting the offset between the BL touch sensor and the first nozzle head, we’ll move on to setting the Z leveling on the second extruder. To do that, you are to use the supplied wrench in order to loosen two screws on the side of the second extruder.

Source: youtube.com

After pushing the hot end down, click Next so that the Wizard can make sure that the extruder is set at the correct height. Then tighten those screws back up and click Next. When the Z-level calibration is done on each of the two extruders, the program will proceed to set the XY to offset between the two extruders to make sure that they are in alignment.

Now the Wizard is ready to level the bed. Click on the Start button to launch the leveling process.

Source: youtube.com

The printer will take various measurements across the build plate and use that information to make sure that the bed is calibrated correctly. The Wizard will notify you in case there is a need to turn any of the adjustment screws.

Source: youtube.com

Now the program will take measurements at various points throughout the plate to make sure that there are no inconsistencies.

Source: youtube.com

The last part of the calibration deals with the filament sensor. You are to select which type of filament you have on either side as well as a temperature to use. Once the hotend heats up, load the filament into the extruders and click Done for the Wizard to start calibrating the filament sensors themselves.

Source: youtube.com

After that, the whole calibration process is finished.

Source: youtube.com

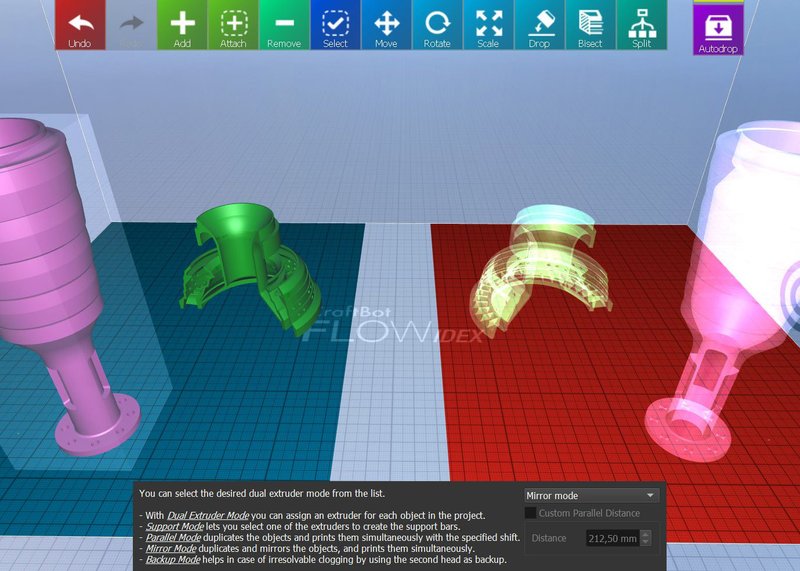

The printer comes with the free own-brand CraftWare slicer; third-party software can also be employed when creating 3D models. CraftWare enables you to easily manage all the printing settings and quickly generate print-ready G-Code files. This slicing program helps reduce build time and find the optimal supports by means of interactive management. It also adopts an impressive G-Code visualizer allowing you to see each print from any angle layer-by-layer to detect areas requiring modification.

Source: craftbot.com

Any user will find the proprietary software convenient and intuitive, whether they be beginners or professionals in 3D printing. More than that, CraftUnique provides its customers with an official tutorial to make the slicer even more user-friendly.

Look at these incredible 350 mm-tall figures made with the CraftBot Flow IDEX by the 3D printing studio fuse3d1. The detail is just amazing.

Source: instagram.com

Source: instagram.com

A Hulk model by polyalkemi. It was printed with a 0.6 mm nozzle and 0.3 layer thickness. As is seen from the picture, the surface finish is nice despite the size of the nozzle. The filament used is Smartfil Chlorophyll Green.

Source: instagram.com

Now that we have described the major distinctive features of the CraftBot Flow IDEX 3D printer as well as seen some use cases, it is possible to summarize the main advantages and disadvantages of the device.

Pros:

Cons:

CraftUnique released yet another masterpiece in the world of 3D printing, allowing makers and professionals to make their work not only faster but more accurate and refined — and therefore of higher quality. With its numerous smart features, the CraftBot Flow IDEX can by right be considered one of the most advanced dual extrusion 3D printers on the market.

Buy the CraftBot Flow IDEX 3D printer from Top 3D Shop and get the original device with an official warranty and the best service possible.

Update your browser to view this website correctly. Update my browser now

Write a comment