How we got this order

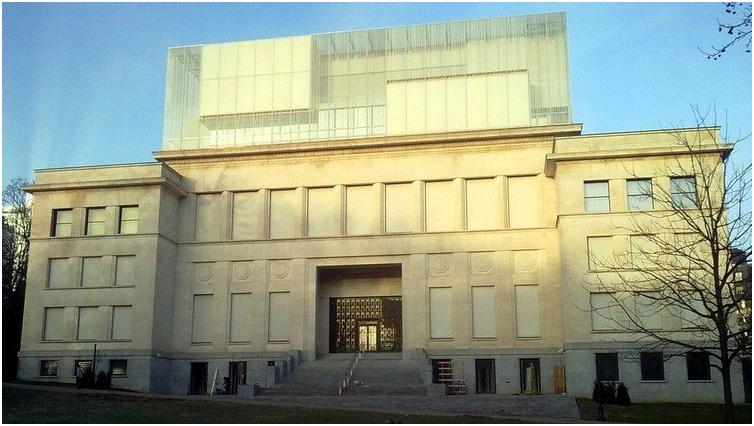

The client was the Brussels House of European History, which belongs to the European Parliament.

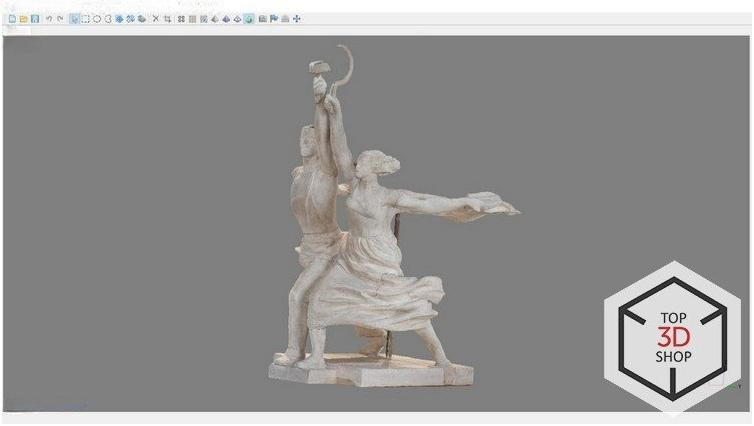

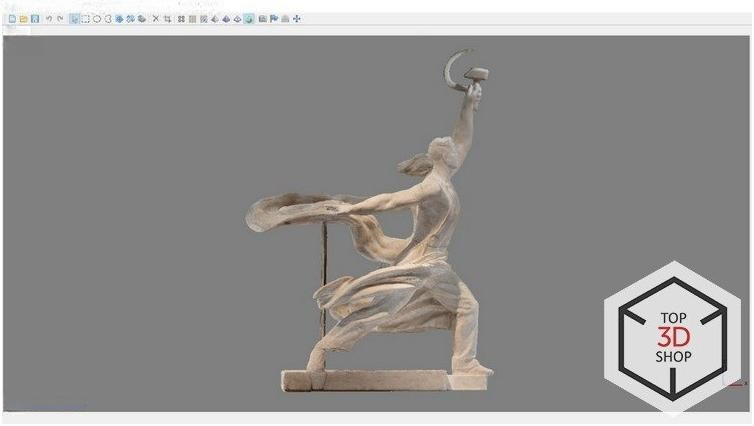

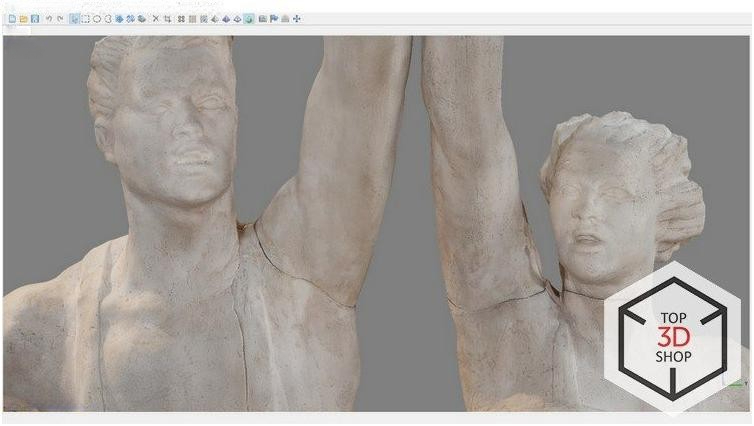

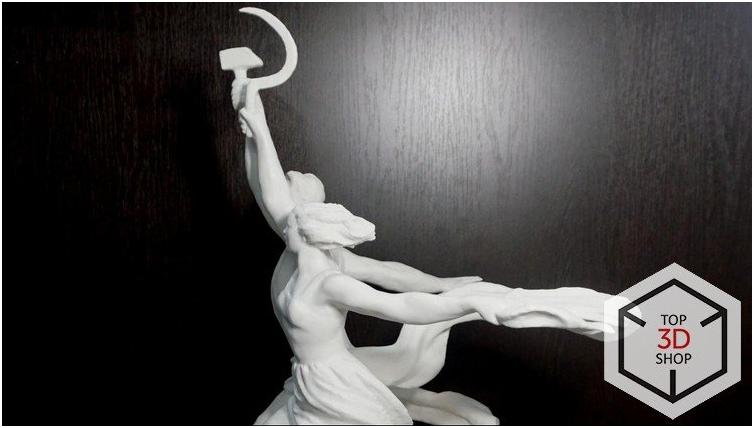

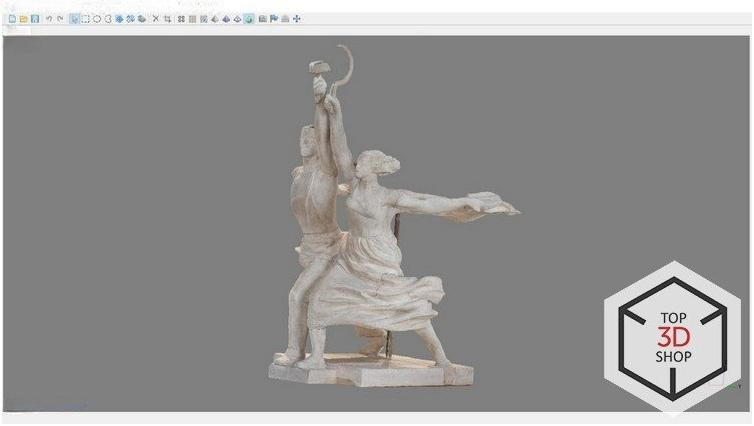

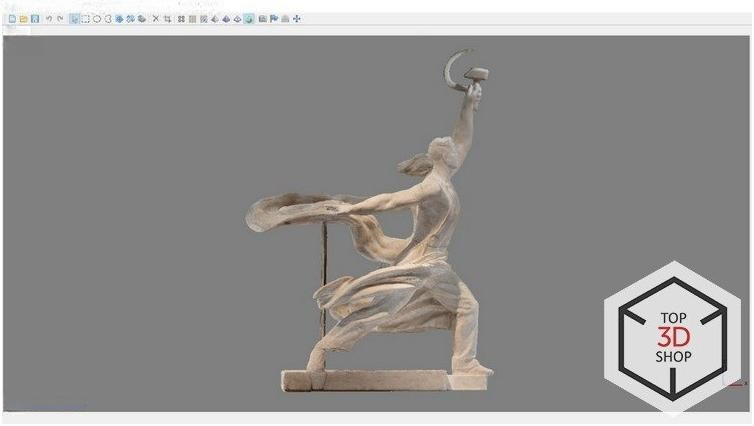

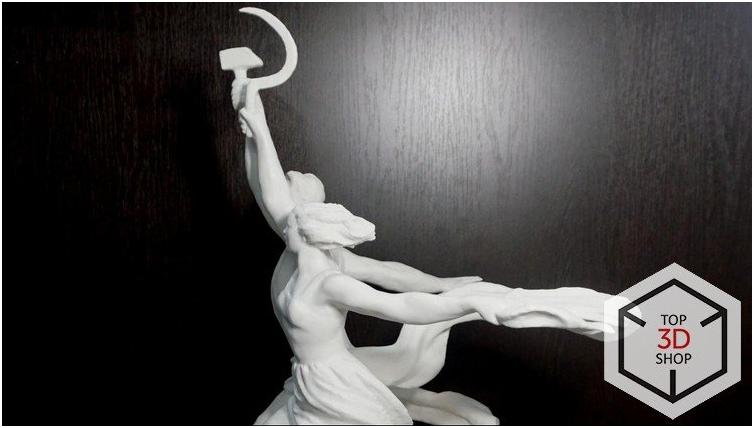

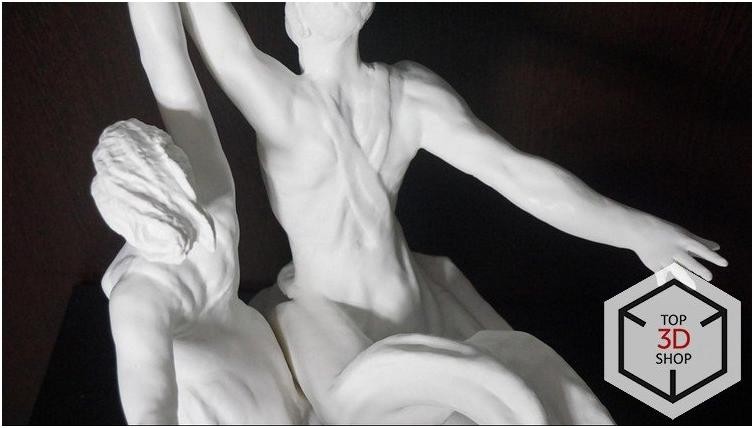

The museum asked us to produce a 3D-printed copy of a sculptural composition — the prototype of the famous Worker and Kolkhoz Woman monument by Vera Mukhina.

The world-known 24.5-meter steel monument comes from this original human-scale plaster sculpture, which now stands in the museum.

Our task:

-

3D scan the plaster original

-

Create a 33% scale replica

-

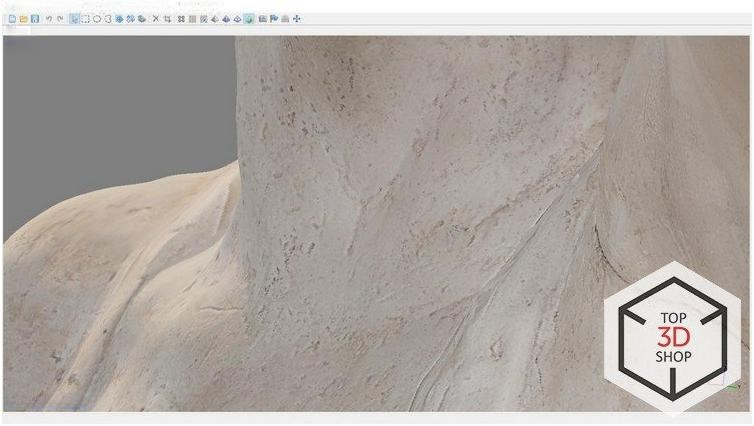

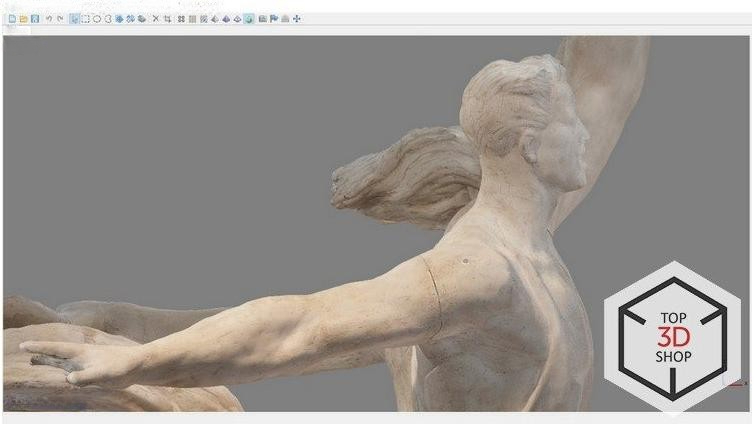

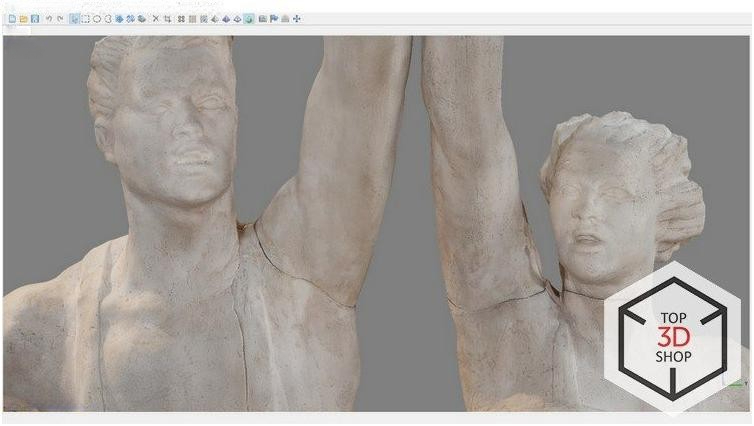

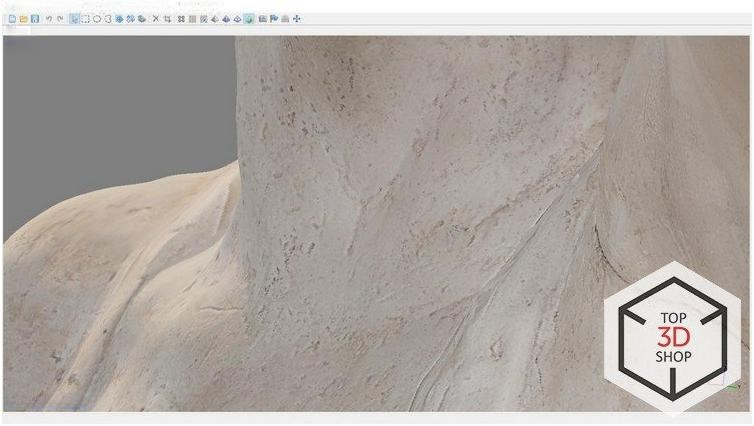

Preserve the proportions, forms, and surface character as accurately as possible

How people used to do this

Before 3D scanning and printing, museums had to invite a skilled sculptor to work directly in front of the original piece.

This approach:

In other words, the human factor limited accuracy and repeatability, and logistical constraints made the work inside a museum even more difficult.

How we did it

3D Scanning

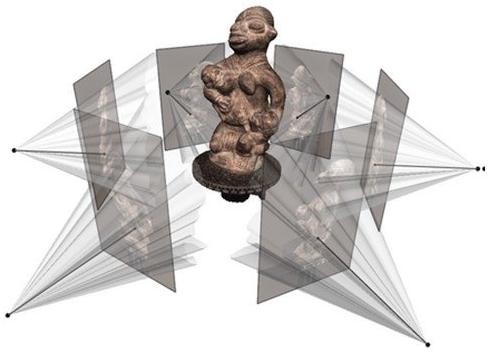

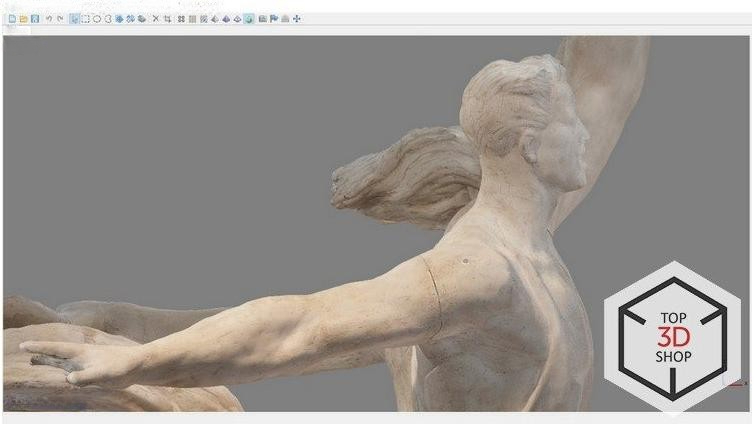

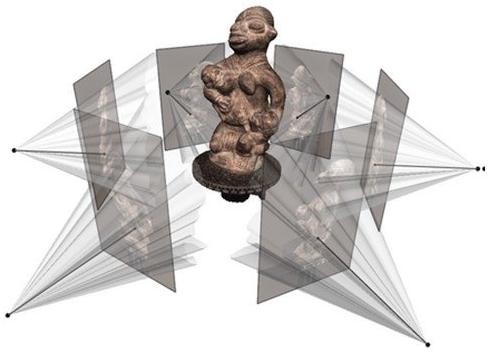

We chose photogrammetric mapping, a 3D-scanning method that builds a digital model from a large series of photos.

The process of photogrammetric mapping looks like this:

In general, photogrammetry can use multiple cameras at once:

In this case, one employee with a professional camera handled the entire project.

We picked photogrammetry because it offers two key advantages for museum work:

Lighting can be tricky with photogrammetry. The museum staff helped us solve this: they moved the sculpture into a well-lit room.

There we:

Timing:

-

Scanning on site: about 4 hours

-

Digital processing (stitching, cleanup, artifact removal): about 24 hours

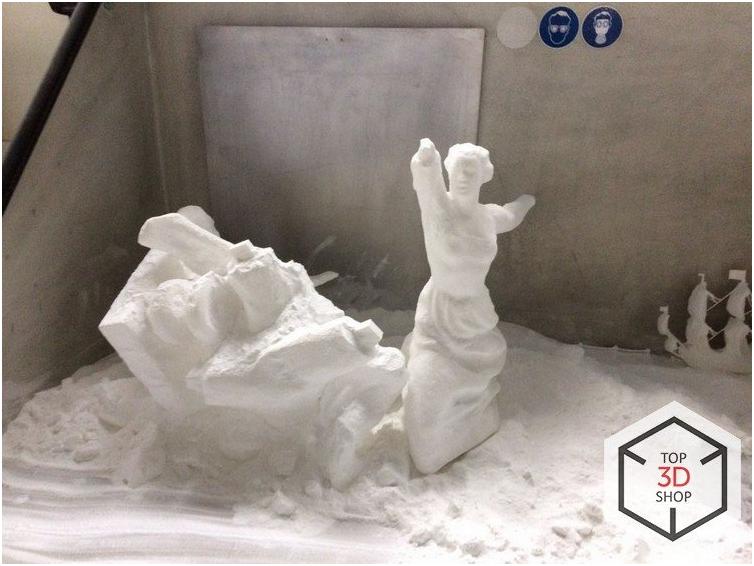

3D Printing

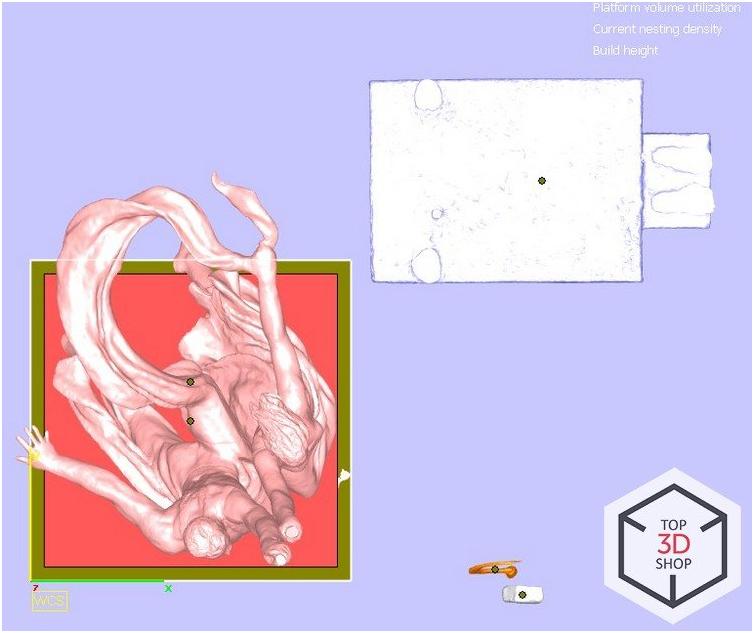

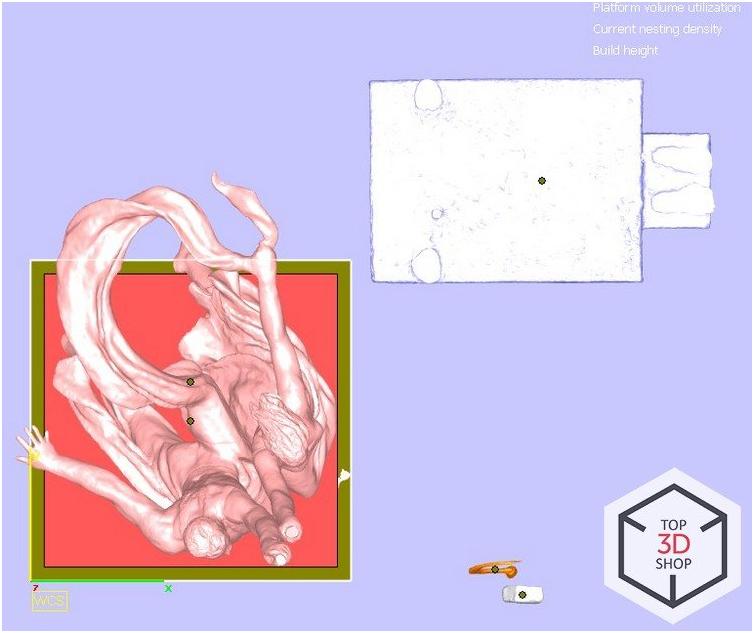

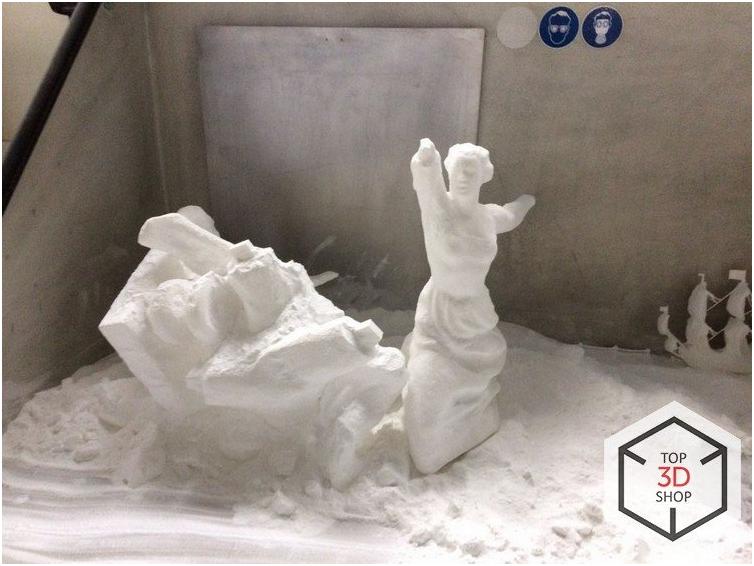

We printed the model in polyamide PA 2200 on an EOS Formiga SLS 3D printer.

EOS Formiga Key Specifications:

-

Technology: Selective Laser Sintering (SLS)

-

Build volume: 200 × 250 × 330 mm

-

Layer thickness: down to 60 microns

-

Printing speed: up to 20 mm/h

We chose:

Printing process:

For maximum accuracy and easier post-processing, we split the sculpture into separate parts:

We printed these elements individually, then:

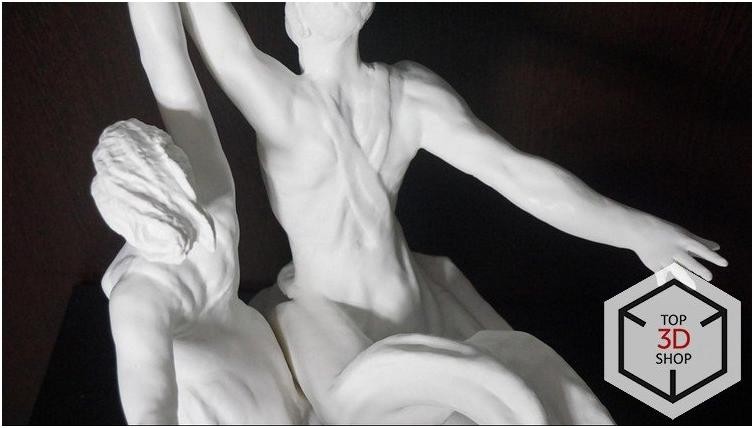

Painting

For finishing, we invited a professional restoration artist.

The goals:

-

Make the PA 2200 model visually match the plaster original

-

Give it the appearance of a freshly produced sculpture, not a worn copy

-

Preserve the original geometry and all fine details while adding the correct tones and shading

The result: a scaled replica that matches both the shape and the visual character of the museum piece.

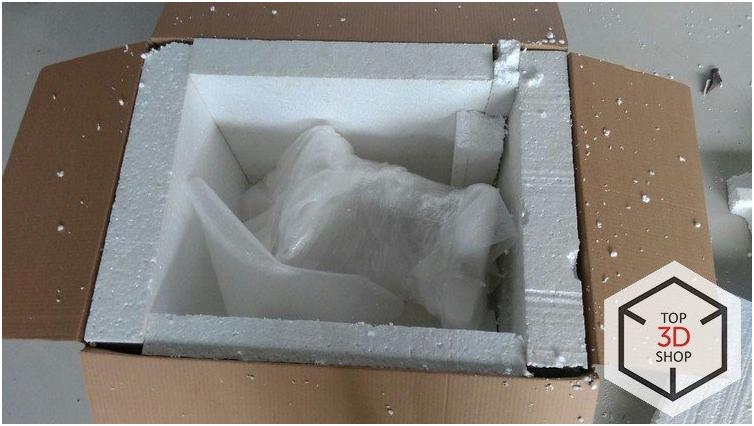

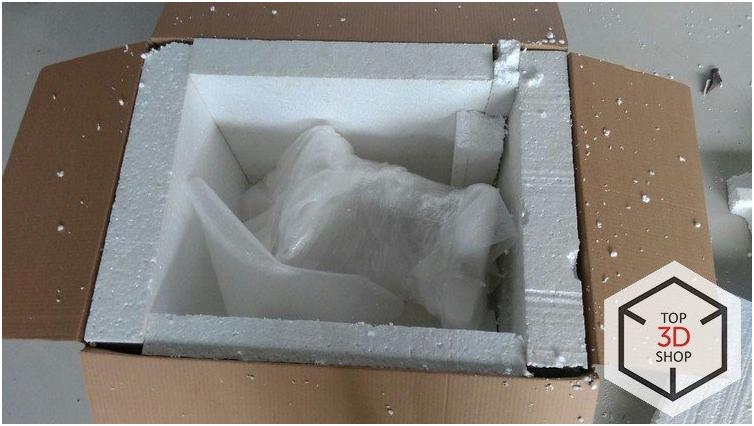

Packaging and Logistics

After painting, we:

-

Carefully packed the sculpture

-

Secured all protruding elements and surfaces

-

Prepared it for transport so it would reach the museum intact and ready to display

Timing and cost

Projects of this complexity — including on-site scanning, digital model processing, 3D printing, assembly, polishing, and artistic painting — typically take about one month from start to finish. We can’t disclose the cost of this specific order because of confidentiality, but the project clearly shows what’s possible when you combine 3D scanning, SLS printing, and professional restoration.

Conclusion

3D technologies help sculptors who prefer to work with digital models instead of sculpting only by hand.

Contact Top3DShop to order 3D scanners and 3D printers for sculptures and other complex objects.

Write a comment