We helped a furniture manufacturer boost productivity and cut costs by automating their welding process with CRP industrial robots. This case study shows how robotic welding improved both output and product quality.

The manufacturer produces over six series of cabinet furniture with metal frames — designed to be durable, practical, and visually appealing. All items are made from environmentally friendly materials.

Their in-house industrial complex handles full-cycle metal processing, including laser cutting (sheet and pipe), bending, powder coating, and welding. With surplus capacity, the company also fulfills external orders.

This producer of office furniture wanted to optimize the welding of steel frames — critical structural components like chair bases and table legs. These parts require precision welding, but the company also needed to keep production costs low, especially for budget product lines.

Manual welding, though performed by skilled workers, was costly due to multi-shift staffing needs. Human error also affected consistency and quality.

Cost Reduction: Robots require only electricity and occasional servicing — no salaries, breaks, or benefits.

Precision and Consistency: Robots follow programmed paths exactly, minimizing defects.

Scalability: Automation supports increased production volume without a proportional rise in labor costs.

After evaluating available options, the company selected CRP robots for their performance-to-cost ratio. Over 12 months, they installed three CRP units — two are already operational.

Setup Included:

Robot: CRP-RH18-20

Welder: Megmeet Ehave CM350AR

Accessories: SC210A torch cleaning station

Key Specs:

6-axis, vertically jointed arm

Max payload: 20 kg

Reach: 1720 mm

Positioning accuracy: ±0.08 mm

Max speed: up to 483°/s (axis-dependent)

Mounting: Floor, ceiling, or rail

IP rating: Body IP54, wrist IP67

Capabilities:

Welding

Plasma and laser cutting

Polishing and grinding

Milling

Material handling

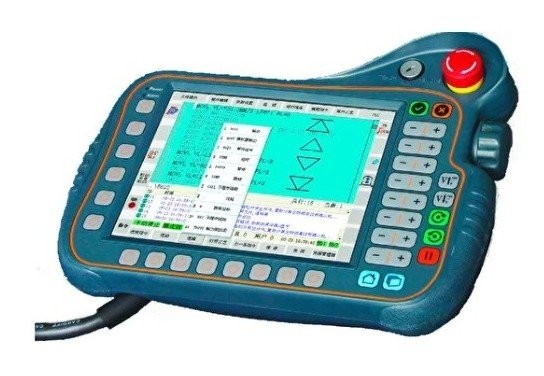

The system includes a C-series control unit with a color touchscreen and emergency stop, offering intuitive programming and operation.

Factory Results:

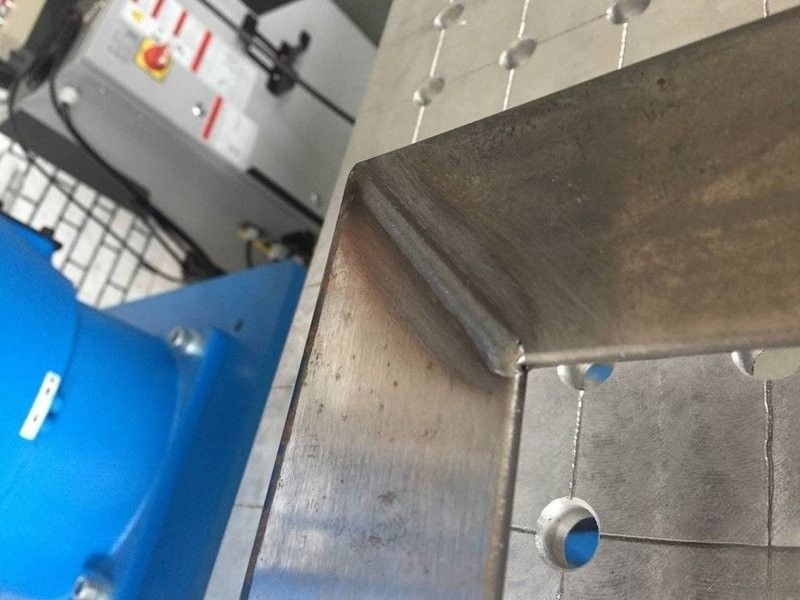

According to the company representatives, the introduction of the robots not only increased the volume of production, but also improved its quality. For example, the weld seams made by robots are always consistent, and some welds are so accurate they do not require any additional cleaning or machining.

Apart from shielding gas welding, the company’s engineers also tried carbon dioxide welding and got great results. In their opinion, this could lead to additional cost savings.

Six months later, the company purchased another set: the CRP-RH14-10 industrial robot with the Megmeet Artsen Plus 350DR semi automatic welder.

Setup:

Robot: CRP-RH14-10

Welder: Megmeet Artsen Plus 350DR

Key Specs:

Max payload: 10 kg

Reach: 1440 mm (ideal for smaller parts)

Speed: Up to 520°/s

Positioning accuracy: ±0.08 mm

Weight: 170 kg

Same IP rating and joint specs as the RH18-20

Functionally similar to the RH18-20 but optimized for small-to-medium workpieces due to its shorter reach.

Reduced labor costs

Higher production speed

Improved and consistent weld quality

Lower reject rates

Satisfied with the results, the company ordered two more robotic welding systems. Management plans to expand operations further, increasing both output volume and product range. Another welding complex with a CRP robot and automated welding platform is already in the pipeline.

CRP industrial robots helped this furniture manufacturer cut costs and improve product quality without sacrificing throughput. Robotic automation in welding is now a core part of their growth and production strategy. Buy robots at Top3DShop to benefit from expert technical support.

Update your browser to view this website correctly. Update my browser now

Write a comment