Founded in 2015, Chinese company Dobot Robotics is known as the creator of the world’s first desktop collaborative robot. Over the years, they have expanded their product range to several lineups with a dozen models varying in terms of payload capabilities and scope of application: CR, CRS, MG400, M1 Pro, Nova, and Magician. According to official data, Dobot has sold over 68000 collaborative robots to 100 countries and regions, which has unsurprisingly made it the first Chinese robot exporter by volume.

With their new CR series consisting of six efficient machines designed for smooth and stable operation, the company opens up new opportunities for collaborative robotics.

This is Top 3D Shop, and today we’d like to take a closer look at specifications and innovative features that make the CR series the next step in safe manufacturing automation.

The DOBOT CR series introduces easy-to-use collaborative robots with plug-and-play architecture that are designed for high-precision repetitive tasks in various working environments. With six available versions differing in terms of payload — from 3 to 20 kg — and reach capabilities, the lineup offers innovative safety functions alongside high performance.

DOBOT CR collaborative robots possess the following characteristics:

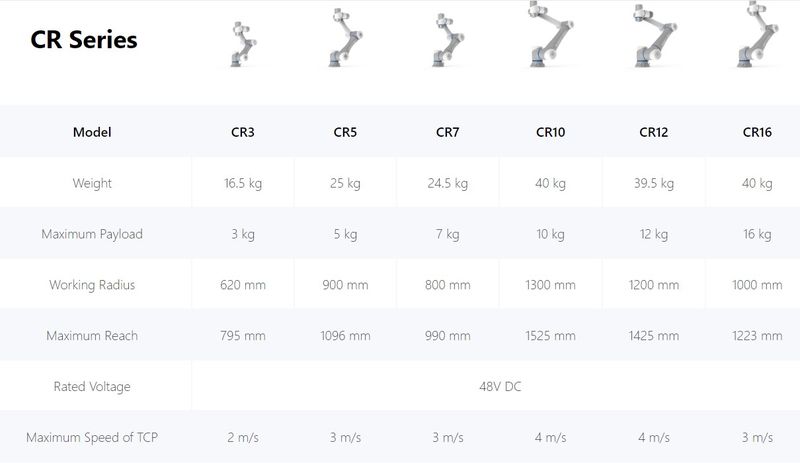

In the picture, you can find the basic technical characteristics of the DOBOT CR machines:

For more information, check out the corresponding product pages in our shop and informative sections below.

Now, let’s look at the prominent features of the DOBOT CR cobots.

The DOBOT CR machines provide reliable performance in combination with high accuracy and stability. With six degrees of freedom, the robots can do the majority of tasks human staff is capable of, but more accurately and with less risk of damage and failure. They can repeat the same movement within ±0.02 mm at a maximum speed of 4 m/s. Considering decent payload capabilities, this lets the CR models perform a wider range of difficult operations.

Apart from the mentioned benefits, the DOBOT CR series is designed with vibration suppression and True Motion algorithms that guarantee precision and stability during complex movements.

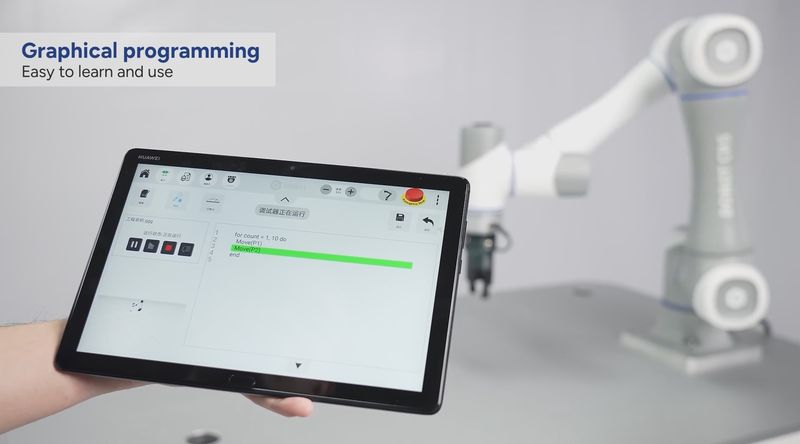

To fit a user of any level, the DOBOT CR machines come with intuitive graphical programming interface and simple scripting, which allows to easily set and adjust tasks from any connected device, with no prior programming experience required. The list of the available terminals includes a smartphone, tablet, PC, and hand-held teaching pendant.

Another convenient function is tactile drag teaching that allows the operator to simply move the cobot to desired positions and set necessary actions. Integrated trajectory tracking and portable learning algorithms enable imitation of human hand motions, which is possible due to all-perceptive AI technology that efficiently combines vision, force, and voice controls.

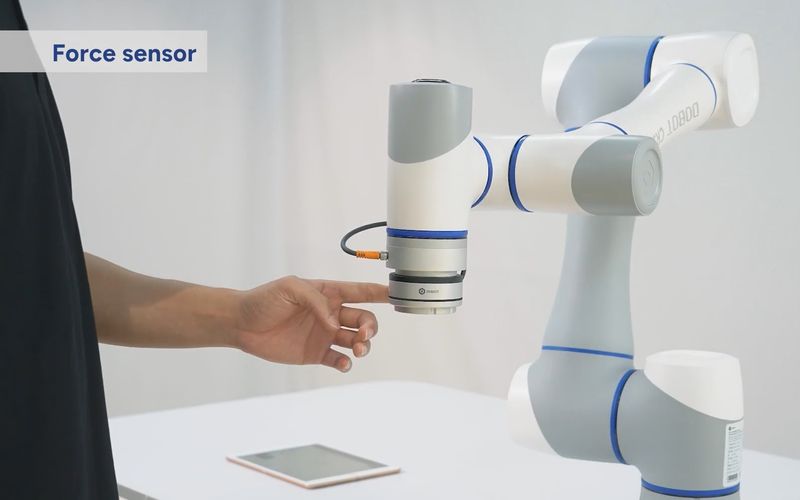

Since safety is one of the priorities when it comes to collaborative robots, the CR series is equipped with multiple sensors offering 5 adjustable levels of collision detection.

This smart mechanism can adapt to a variety of application scenarios and boasts quick response of up to 10 ms at a distance of 15 cm. Moreover, it provides an obstacle avoidance mode with no material interference.

The innovative pre-collision sensing technology known as SafeSkin represents an optional silicone shell accessory for the CR3, CR5, and CR10 models. Attached to J4 and J6 joints of the robots, SafeSkin boasts high surface coverage, long sensing distance, and rapid response. So, this cutting-edge mechanism takes human-machine collaboration to a whole new level.

All these smart features make the CR cobots injury-free at low and medium speeds and guarantee 90% less collision damage during high-speed operation.

Thanks to ergonomic design with plug-and-play architecture and simplified wiring, the DOBOT CR devices ensure a fast and easy deployment. The complete installation process takes no more than 20 minutes, so the cobot is ready for work in just an hour.

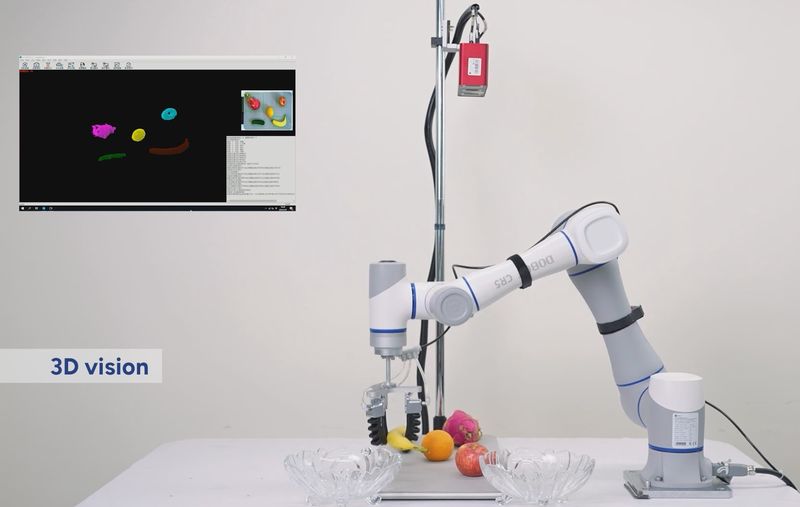

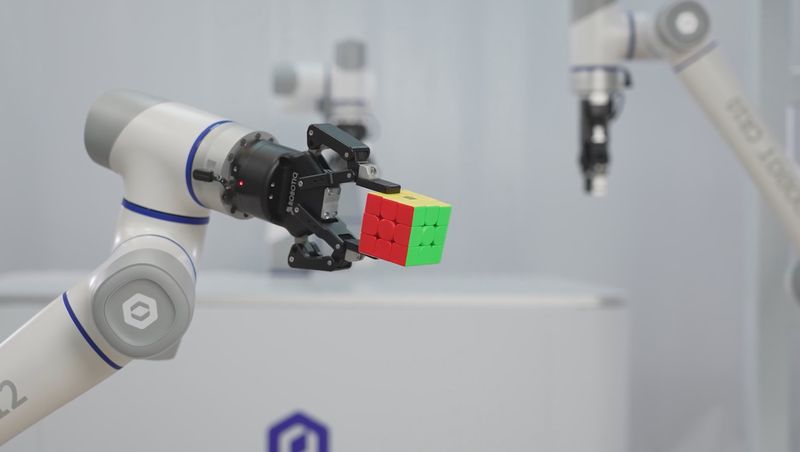

To fulfill an even greater variety of tasks, the CR collaborative robots are equipped with multiple I/O and communication interfaces. They are compatible with a wide range of plug-and-play end-tools, such as grippers, cameras, and sensors.

DOBOT CR cobots are aimed at high adaptability and versatility. Due to official software packages that cover more than 50 tasks across 8 major industries, they can master all manner of traditional operations, including loading and unloading, assembly, screwdriving, welding, polishing, etc.

These ergonomic, easy-to-use machines will become perfect tools for a wide range of industries, including automotive, consumer electronics, semiconductor, healthcare, chemical, and new retail.

Depending on their individual features, the DOBOT CR cobots will fit different spheres of application.

From the official website, we have gathered just a few examples of use of the DOBOT CR series.

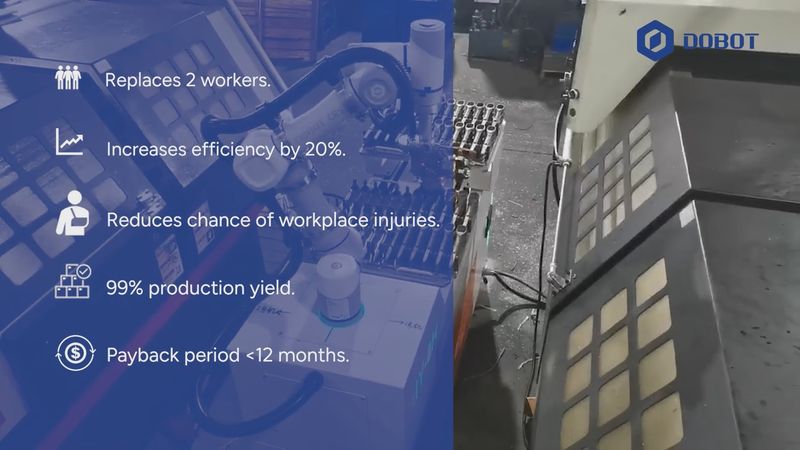

While manual loading and unloading is inefficient and unsafe, there were some other problems for the customer, namely — insufficient space and high price of traditional automation equipment. Luckily, a CR5 robot equipped with a double gripper is able to manage unprocessed and processed parts from two machine tools at once, which greatly improves production efficiency and cost.

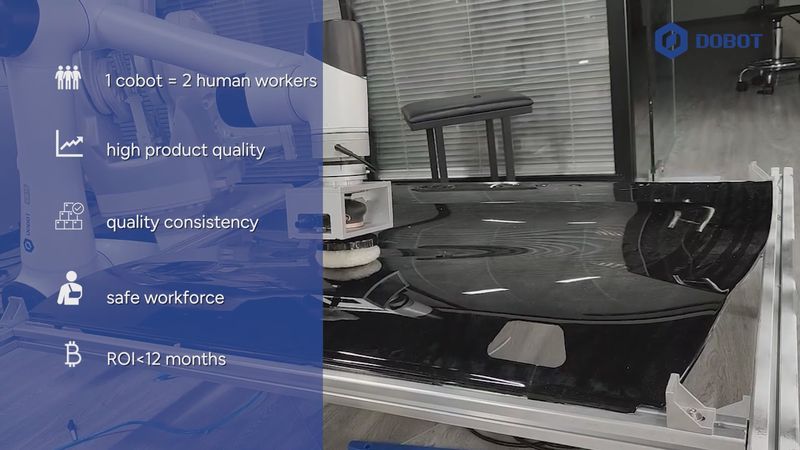

Not only is the polishing process difficult to control by manual operation, but in this case the working environment is dangerous for workers: resulting dust can cause professional diseases.

To reduce labor costs and achieve better outputs, the customer decided to deploy a DOBOT CR5 robotic arm with a force sensor and grinding head installed. Thanks to force perception and adaptive compensation technology, it can successfully adapt to high-quality polishing of irregular surfaces, such as car roof surfaces and doors.

As with many traditional technical operations, manual screwdriving is inefficient. Too much force can easily damage the screw holes, which affects product consistency.

However, with a CR16 collaborative robot equipped with proper accessories, the pre-tightening task of the screw set of a gearbox can be completed within 32 seconds. Apart from dealing with two screws at the same time, the robot is able to continuously follow the exact procedures and scheduled workflow.

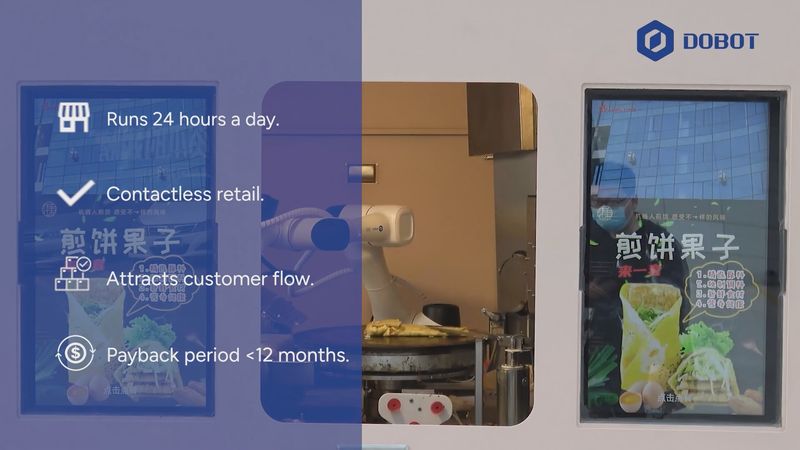

In retail, staff training takes a long time. Additionally, it implies hard business hours with unstable customer flow. With suitable end-effectors, collaborative robots from the DOBOT CR series can prepare food and drinks based on customer orders. For example, this particular cobot completes the full process of baking Chinese pancakes, from making the mixture to delivering the finished product, in 3 minutes.

In summary, the collaborative robots from the DOBOT CR series effectively combine a flexible design, decent working radius, high precision, cutting-edge safety technologies, and intuitive controls, which makes them ideal for a wide spectrum of operations in multiple spheres where repetitive tasks have to be performed accurately and reliably.

The reasonable implementation of the DOBOT CR series allows one not only to automate manifold production processes, save time and costs, but also maintain safety and health of human staff working alongside these intelligent machines.

Update your browser to view this website correctly. Update my browser now

Write a comment