Hi everyone! Today, we will tell you about JAKA collaborative robots — their functionality, features, and applications. Read the review to learn more about some of the most advanced robotic arms to date.

The Chinese company JAKA Robotics was founded in 2014. Its major sphere of activity is the development and manufacture of collaborative robots and intelligent production lines. JAKA Robotics is headquartered in Shanghai.

The current line of JAKA 6-axis cobots includes the basic Zu series — robots with a payload capacity of 3, 5, 7, 12, and 18 kg, which is reflected in the model name: for example, the JAKA Zu 18 is a robot from the basic series with a payload capacity of 18 kg.

Similar models with the S index are distinguished by the inclusion of force torque sensors in the design: for example, the JAKA Zu 18S.

In September 2020, the company introduced a new lineup called All-in-one (abbreviated Ai), which is equipped with machine vision cameras.

Separately, there is a tiny compact model called JAKA MiniCobo.

The Zu series includes five models of collaborative robots — Zu 3, Zu 5, Zu 7, Zu 12, and Zu 18. The reach of the Zu series cobots ranges from 626 to 1327 millimeters. The repeatability of the Zu 3, 5, and 7 models stands at 0.02 mm; in the Zu 12 and 18, it is 0.03 mm. The weight of the cobots varies from 12 kilograms in the Zu 3 model to 41 kilograms in the Zu 12.

|

Zu 3 |

Zu 5 |

Zu 7 |

Zu 12 |

Zu 18 |

|

|

Weight |

12 kg |

23 kg |

22 kg |

41 kg |

35 kg |

|

Payload |

3 kg |

5 kg |

7 kg |

12 kg |

18 kg |

|

Reach |

626 mm |

954 mm |

819 mm |

1327 mm |

1073 mm |

|

Repeatability |

±0.02 mm |

±0.02 mm |

±0.02 mm |

±0.03 mm |

±0.03 mm |

The JAKA Zu S series retains all the characteristics of the basic models, the only difference being the presence of force torque sensors.

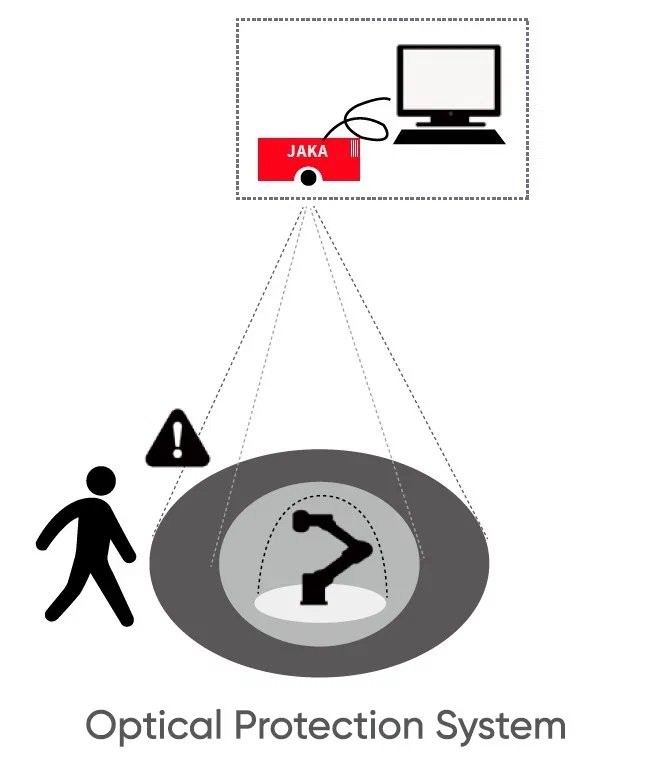

The key features of the whole lineup include wireless control, collision detection system for safety purposes, fast programming, real-time monitoring, and an ecosystem that combines open source software and hardware.

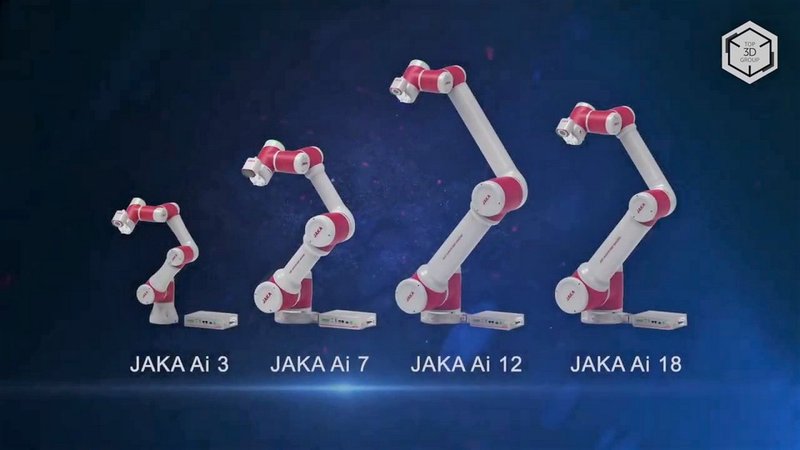

The new JAKA Ai series of cobots, too, includes five models: Ai 3, Ai 5, Ai 7, Ai 12, and Ai 18. It was designed in accordance with the S3 principles — Smart, Simple, Small.

The robots from this line support wireless training, visual programming, and machine vision for personnel safety.

While the machine vision system can be purchased separately for the Zu cobots, the design of the Ai already has it included and integrated. Also, the Ai is offered with a special mini-cabinet — a compact version of the control unit for installation in confined spaces or on a mobile platform.

In the summer of 2021, JAKA Robotics unveiled the MiniCobo, its smallest collaborative robot ever.

The technical characteristics of the JAKA mini-cobot make it ideal for the use in catering and service sectors as well as education.

Thanks to its small size and modest energy consumption, the MiniCobo will find its place just about anywhere, from a cafe or a school class to a design office and a workshop.

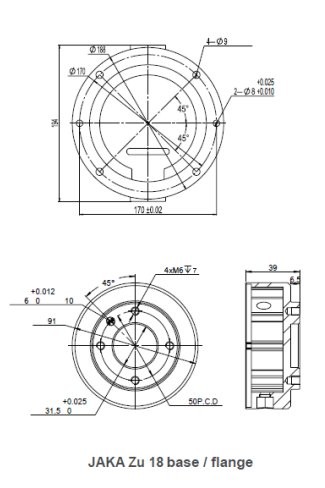

The JAKA Zu 18 is a collaborative robot with a manipulator range of up to 1073 mm, a payload of up to 18 kg, and a weight of 35.3 kg. Its integral connections simplify assembly and disassembly of the robot, which can be installed at any angle. The body of the device is made of aluminum and PC, ensuring durability and strength. The Zu 18 is the largest cobot in the manufacturer's lineup.

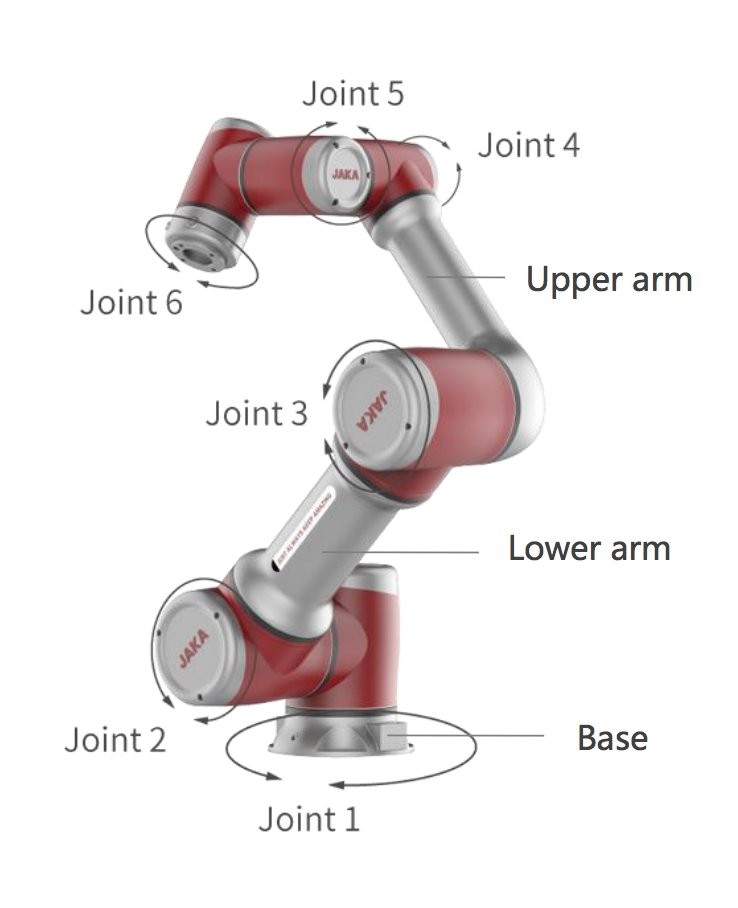

The six joints provide high maneuverability of the cobots.

The force torque sensor is located at the base of the robot or at the sixth joint.

The force torque sensor is located at the base of the robot or at the sixth joint.

Thanks to the open hardware and software solution, the equipment easily integrates into existing production systems.

The cobots can be programmed via PC or manually; control through the application is carried out on a computer or a mobile device.

The joints are unified, making assembly and disassembly of the JAKA cobots quick and easy.

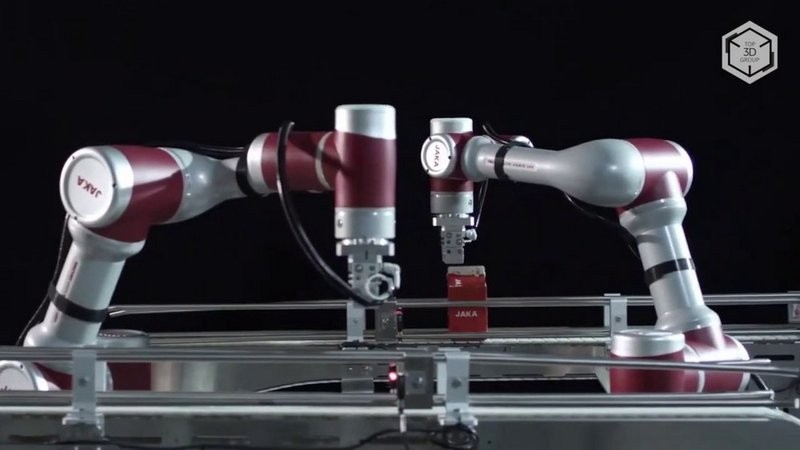

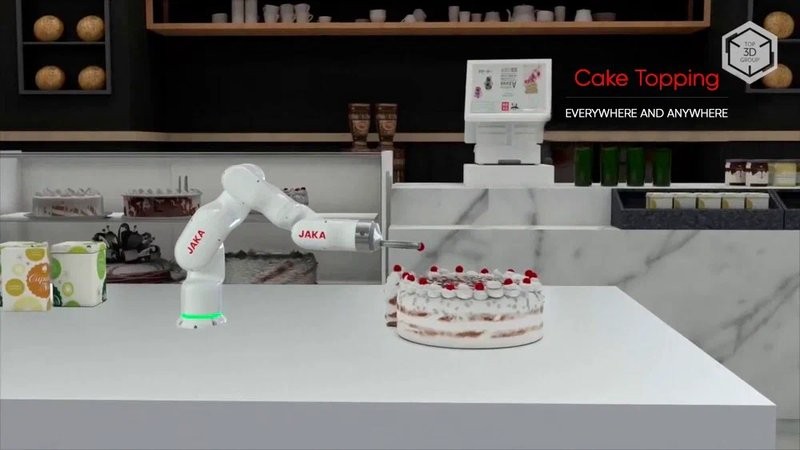

JAKA cobots are versatile devices ready to be employed in a wide variety of applications.

JAKA collaborative robots are used in the production of various goods and services for individuals and organizations — automotive products, electronics, industrial machines, medical products (as well as optimization of medical and pharmaceutical processes, such as dispensing medicines or testing), electrical appliances and food, alternative energy and chemical industries, scientific research and education, injection molding of plastics, metalworking, and all kinds of entrepreneurship.

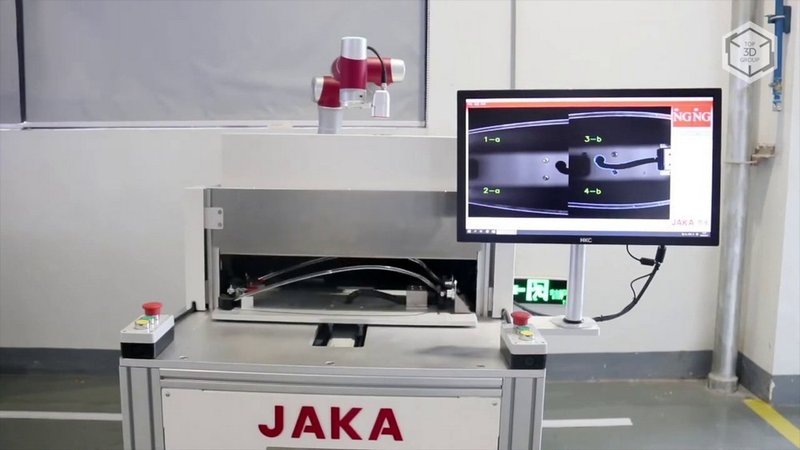

In industries, JAKA is particularly used for automatic quality inspection — this is one of its most demanded applications.

Below are only some of the countless possible applications of JAKA cobots.

The JAKA collaborative robots are versatile equipment designed to simplify production processes to an unprecedented extent. All of the models feature great accuracy, repeatability, and flexibility, having also a sturdy and reliable structure. The only question that remains is what working range and payload you need your cobot to have — with a variety of options in the lineups, you will definitely find the model for your requirements.

Update your browser to view this website correctly. Update my browser now

Write a comment