Hi everyone! This is Top 3D Shop, and in today’s article, we are going to tell you about the xArm collaborative robots by the Chinese manufacturer UFACTORY. These cobots are used in production of various scales and directions, featuring a great variety of applications.

Read more about the xArm lineup and accessories from this review.

UFACTORY specializes in the design and manufacture of robotic arms for the consumer market. The company's office is located in Shenzhen, the center of concentration of the Chinese industry. UFACTORY was founded by a group of experienced robotics developers who are committed to transforming the robotic ecosystem. To do this, they promote industrial technologies by providing cost-effective products and integrated solutions for a variety of industries.

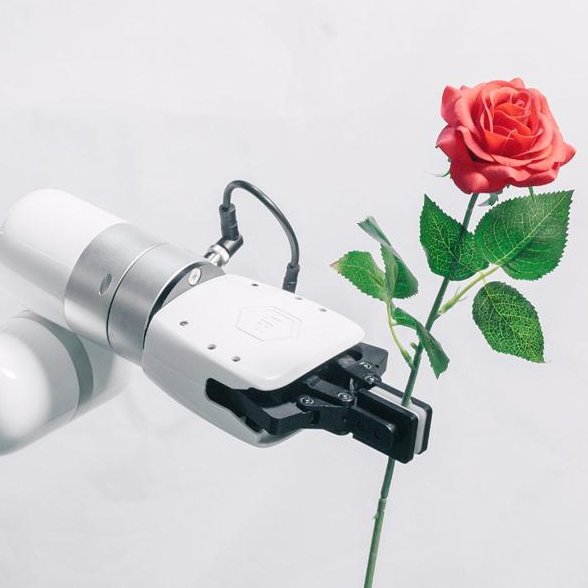

Source: instagram.com

UFACTORY's mission is to demonstrate that robotic technologies are useful and will be of great help in everyday life for future generations.

The first project of the company was the uArm robot, which was successfully funded on the Kickstarter crowdfunding platform. The robotic arm has received numerous positive reviews from users around the world. The uArm Swift Pro is the next development of the company, it has raised over a million dollars and became the most funded robotic arm on the crowdfunding platform. The uArm robotic arms are sold in over 80 countries and are featured regularly in the media.

The next development of UFACTORY is the line of collaborative robots xArm.

Source: store.UFACTORY.cc

The xArm lineup is represented by the xArm 5 Lite, xArm 6, and xArm 7 robots, as well as a few accessories. The robotic arms are optionally supplied with the xArm Gripper, the Camera Module, and mounts for the xArm Spare Parts.

The xArm 7 collaborative robot is the biggest model of the xArm family. It has 7 joints, due to which it is characterized by increased maneuverability. It can move, rotate, and reach objects located at a distance of up to 700 mm. The arm capacity is 3.5 kg. The weight of the robot itself is 13.7 kg.

Unlike industrial bulky robotic manipulators, the xArm 7 is lightweight as it is made of carbon fiber and aluminum.

The xArm robot couplings are designed as compact geared motors with a 17-bit encoder.

Source: store.UFACTORY.cc

The robot's software is based on the xArm studio platform and has an intuitive graphical interface, which significantly reduces the labor costs of programming the robot.

The robotic arm copes not only with simple tasks, such as transferring items, sorting, placing items on the conveyor, but can also perform complex operations — assembly, grinding, loading workpieces into machines.

Apart from being programmed to perform certain actions through the program interface, the xArm 7 can also be taught manually. The user just needs to move the robotic arm, showing the path of the performed action, and the robot will record the sequence of movements and then accurately reproduce them.

The xArm 5 Lite and xArm 6 robots differ from the xArm 7 model in the number of joints — they have five and six, respectively — and also in the payload.

The xArm 5 Lite robotic arm is the youngest and most affordable model in the line. Its payload is 3 kg, with a repeatability of ±0.1 mm. The xArm 5 Lite cobot has five joints, its reach is 700 mm, and it weighs 11.2 kg.

The xArm 6 and xArm 5 Lite models are suitable for pick-and-place operations and performing repetitive actions.

The next model in the series is the xArm 6 robot. The arm's load capacity is 5 kg, the repeatability being ±0.1 mm. It differs from the xArm 5 Lite model in the presence of an additional sixth axis. The weight lifted has been increased to 5 kg. The weight of the manipulator itself is 12.2 kg.

The six joints allow the device to move smoothly in all directions. In addition to picking and placing items, the xArm 6 is ideal for loading assembly, packaging, and palletizing machines.

The main differences between the xArm models are shown in the table:

|

model |

xArm 5 Lite |

xArm 6 |

xArm 7 |

|

speed |

0.33 m/s |

1 m/s |

1 m/s |

|

freedom degree |

5 |

6 |

7 |

|

payload, kg |

3 |

5 |

3.5 |

|

weight, kg |

11.2 |

12.2 |

13.7 |

Source: store.UFACTORY.cc

The xArm Gripper is a two-finger gripping tool with an opening of up to 86 mm. It is suitable for working with a wide variety of different objects.

Source: store.UFACTORY.cc

The gripper has a built-in 12-bit encoder, which allows gripping fragile objects.

Supply voltage: 24VDC (max. 28VDC)

Static power consumption: 1.5W

Peak current: 1.5A

Max. gripping force: 30N

Stroke: 0–86 mm

Weight: 822 g

Communication mode: RS-485

Communication protocol: Modbus RTU

Programmable gripping specifications: position, speed, force

Source: store.UFACTORY.cc

The module is equipped with the Intel RealSense D435 camera, which is one of the most popular RGB-D cameras on the market. The mounting plate provides an easy way to install the camera on the xArm, and the 2m USB Type-C cable provides a stable and high-speed connection. An additional computer is required to connect the camera module.

Tech specs:

Camera: Intel RealSense D435

Ambient temperature: 0–50 °C

Weight: <200g

Connectivity: USB Type-C

Source: store.UFACTORY.cc

The xArm DC Control Box is a fully functional compact controller for mobile platforms. It contains the same motherboard and I/O expansion. When removed, the AC adapter is 1/3 the weight and 1/3 the size of an AC adapter. It is powered by 24VDC only.

Controller specifications:

|

model |

AC Control Box (default) |

DC Control Box |

|

input |

100-240VAC, 50/60Hz |

24VDC |

|

output |

24VDC, 20.8А |

24VDC, 16.5А |

|

weight |

3.8 kg |

1.6 kg |

|

dimensions |

280 х 200 х 116 mm |

180 х 145 х 68 mm |

|

control box I/O |

8 CI (digital IN); 8 CO (digital OUT) 2 AI (analog IN); 2 AO (analog OUT) |

|

|

communication |

Ethernet/RS-485 |

|

Source: store.UFACTORY.cc

Robot mounts are supplied optionally. They allow you to stably fix the device on the table. The kit contains two clamps and a mounting plate.

Source: store.UFACTORY.cc

The xArm cobots are supplied with the following items:

Before starting to work, you need to fix the robot on the table. To do this, it is most convenient to use the brackets, which are supplied separately. Then, if necessary, a gripper, suction cup, or camera is screwed to the arm with a Phillips screwdriver.

The xArm robots come with the xArm Studio software. Due to the fact that the work of robots is still not intuitive enough, xArm has simplified the process of controlling devices as much as possible.

There are three levels for interacting with robots: Teach Mode, GUI Programming, and Programming IDE. Teach Mode is manual teaching of robots by movements with recording and subsequent replication. GUI Programming is control of the robot's movements on the monitor by combining blocks with the description of movements: up, down, turn, etc. GUI Programming is suitable for beginners and non-versed users. Programming IDE is a robot control designed for engineers.

The xArm Studio has a Real-Time Control mode and runs on Windows, macOS, Linux, and Android operating systems.

Source: www.facebook.com

In the near future, the xArm 5 Lite, xArm 6, xArm 7 cobots may find wide application in the field of public catering. They can be trained to operate coffee machines, serve dishes on plates and drinks in glasses, add sauces and spices, work in a confectionery industry (for example, decorate cakes). In everyday life, these skills are applicable to robotic cooking at home.

The xArm 5 Lite, xArm 6, and xArm 7 can be trained to take photos and videos. This function is suitable both for creating entertaining content (e.g. food blogging), and for recording scientific experiments that require high-precision shooting.

Source: www.facebook.com

With flexibility similar to that of a human arm, xArm 7 robots can literally become an additional arm for their owner. What is more, the robot can serve as an assistant for people with disabilities. The xArm 7 can move objects and perform operations with household appliances — blow-dry hair, clean clothes, etc.

Source: www.einscan.com

xArm robots are widely used in manufacturing. They easily cope with the packaging and palletizing of goods, can reach and move parts using machine vision systems. The robots can be configured for machine tending, for example, to load workpieces.

Source: instagram.com

The xArm are useful not only in production. They can be used in various fields, for example, in sports medicine, as a "robot massage therapist" to relieve neck pain, and for other purposes.

The xArm 6 and the Elfin E5 robots are the products of two competitive Shenzhen-based companies. The robotic arms have similar characteristics: a speed of 1 m/s, a lifting capacity of 5 kg, a reach of 700 and 800 mm. At the same time, the xArm 6 is twice as light — 12.2 kg versus 23 kg. This can be a significant feature if mobility in production or frequent movement of the device is required.

Both devices are collaborative, that is, they are designed to work in close proximity to a human, they are flexible and easily reconfigurable. Additional advantages of the Elfin E5 are EtherCAT communication and two programming languages.

The Han's Robot Elfin E5 and the UFACTORY xArm 6 are used in medicine, production, and are suitable for fulfilling tasks of the consumer market. With similar functionality, the cost of the Elfin E5 is higher.

still high price.

The UFACTORY xArm robotic arms are designed to make life easier for people and simplify production tasks. They greatly cope with sorting and packing, tending machines in production, pick-and-place actions, photo and video shooting, scientific research. A few years ago, such a robot would have cost about $50,000. UFACTORY managed to bring models that cost far less, making them affordable for small industries.

Update your browser to view this website correctly. Update my browser now

Write a comment