In terms of ever-evolving industries, we face increasingly severe working conditions that are frequently not suitable and even dangerous for human staff. Luckily, robotics is here for us to extend a helping hand.

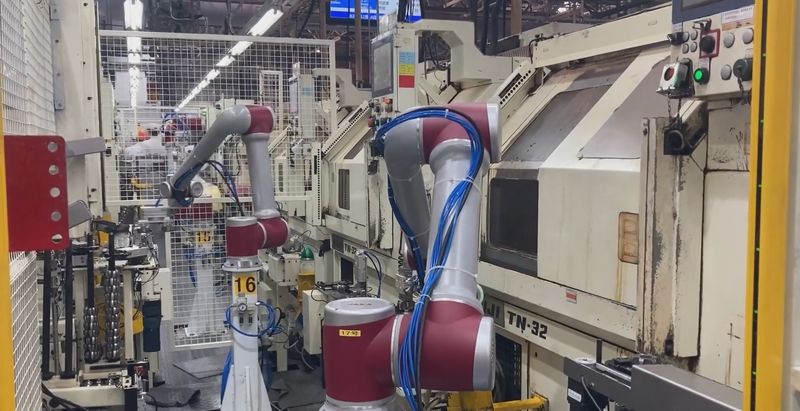

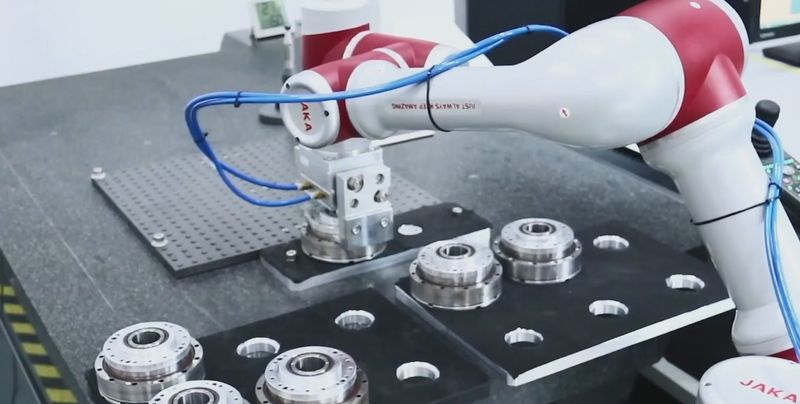

Chinese company JAKA produces compact and lightweight collaborative robots for multiple industrial automation purposes, including assembly, packaging, palletizing, welding, inspection, and more. With their new Pro series consisting of three efficient machines designed for harsh operating environments, JAKA opens up new opportunities for some really challenging spheres.

Let’s take a look at their main characteristics and find out what the JAKA Pro collaborative robots are capable of.

The JAKA Pro series introduces industrial collaborative robots built for high-precision demanding tasks in various working environments. With three available versions differing in terms of payload and reach capabilities, the lineup features important brand characteristics in combination with several innovative solutions making the machines suitable for really demanding applications.

All JAKA Pro cobots possess the following characteristics:

For more information, check out the sections below.

Now, let’s take a closer look at the prominent features of the JAKA Pro collaborative robots.

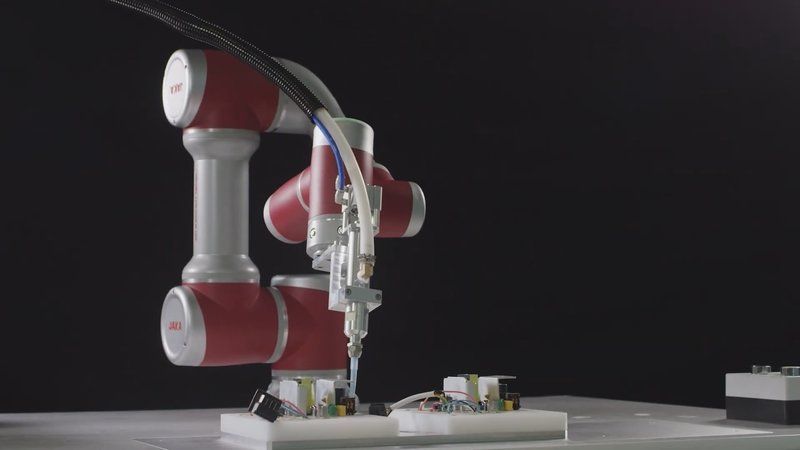

The JAKA Pro cobots provide stable and reliable performance in combination with high maneuverability and remarkable precision. With six degrees of freedom, the machines can do the majority of tasks human staff is capable of, but more accurately and with less risk of damage and failure.

The Pro models can repeat the same movement within ±0.02 mm at a maximum speed of 3 m/s. In combination with decent payload capabilities depending on the version, this lets them perform even the most difficult operations with consistency and ease.

Designed for work in harsh environments, the JAKA Pro collaborative robots boast a high rating of ingress protection — IP68. It ensures full immunity to small particles and liquids, such as water, dust, oil, metal, wood, glass or plastic shavings. Combined with resistance to low and high temperatures (-10–50 °C), the machines remain completely functional even in a desert or rainforest.

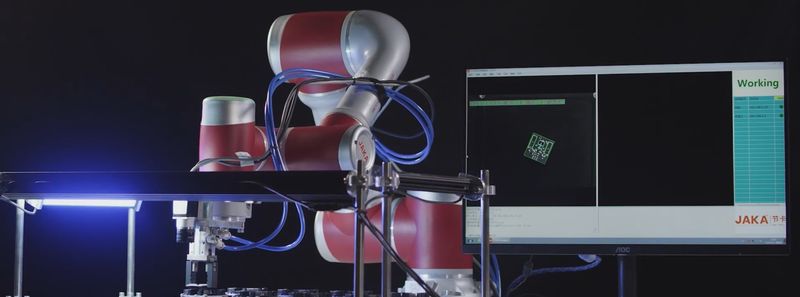

In terms of software, the JAKA Pro cobots are powered by the proprietary JAKA APP, which offers a user-friendly interface in combination with intuitive graphical programming features. Due to this, users of all levels and skills are capable of mastering the program in no time. With the JAKA Pro robots, it is very easy to assign and monitor tasks from any connected device, with no teaching pendant required. The JAKA APP is available on tablets, smartphones, and PCs, which makes it truly accessible.

Another valuable function of the series is tactile drag teaching that allows the operator to simply move the cobot to desired positions and set necessary actions in the programming interface, even without previous robotic experience.

One can also select from a number of basic commands built into the Pro series interface to start the working process in just a few minutes after installation. Thus, anyone can achieve task automation with the JAKA Pro machines right out of the box.

Thanks to advanced network connectivity, the JAKA Pro cobots can be fully controlled regardless of the user’s position ensuring smooth and effective automation. Remote monitoring feature allows one to program various tasks and watch over the robot’s performance from any part of the world. Conveniently, in case of any issues, corresponding alerts will be raised right away.

All the JAKA Pro series cobots come with the integrated torque-feedback collision detection, which ensures complete safety and comfortable working conditions for human staff. When a person comes into contact with the device, the latter immediately stops. So, no safety fences are necessary around the JAKA Pro collaborative robots that leads to quick and efficient introduction of the machines.

JAKA cobots are designed with a rapid integration and endless adaptability in mind. They can seamlessly master all manner of applications, from inspection to assembly, palletizing to welding and more. With their advanced functionality, the JAKA Pro robots easily fit into any mixed or purely automated line and cover the majority of industrial operations of demanding and repetitive character.

According to their individual features, the JAKA Pro cobots serve various purposes based on their technical characteristics.

For example, the JAKA Pro 5 is the smallest model in the series yet providing a decent reach of up to 954 mm alongside its minimum payload estimated at 5 kg. This combination makes the cobot ideal for a wide spectrum of precise repetitive tasks including machine tending, gluing, vision picking, and testing. The device is particularly great for metal, wood, machining, and other industries involving challenging environments.

The JAKA Pro 12 offers the second best reach of 1327 mm coupled with a higher payload stated in the model name. It also has a wider range of appropriate operations, such as assembly, inspection, polishing, palletizing, packaging, machine tending, welding, etc. The machine will prove itself extremely useful in many modern industries requiring high precision and durability, from automotive manufacturing to agriculture.

As for the last available model, the JAKA Pro 16 boasts an outstanding reach of 1713 mm combined with 16 kg payload. Due to its remarkable speed and repeatability, this powerful robot is well suited for cutting metal, grinding, machine tending, and other heavyweight factory automation tasks that involve metal shavings, sawdust, oils, or other liquids. The list of industries that will benefit most from the JAKA Pro 16 includes machining, automotive, agriculture, food, etc.

The Pro cobot series from JAKA marks the new stage in industrial automation. It introduces collaborative robots with high-quality protection against various production threats while providing remarkable accuracy and speed important for precise repetitive tasks. The presented models can cope with a wide range of applications in need of robotic process automation due to harsh working conditions, from machine tending and palletizing to assembly and inspection. Thanks to intuitive programming, thoughtful safety protocols and easy controls, the JAKA Pro cobots enable smooth and hassle-free experience both for beginners and experienced manufacturers looking for new production optimization opportunities.

Update your browser to view this website correctly. Update my browser now

Write a comment