Hi everyone! This is Top 3D Blog with a special case study review. In this article, we are going to tell you how additive manufacturing technologies are applied in creating complex replicas of football stadiums. As always, we are going to dwell upon the employed techniques and equipment, highlight the pros and cons of using additive manufacturing technologies in such applications and provide you with an in-depth review of four cases to lay out the workflow in greater detail. Let’s find out how cutting-edge manufacturing technologies can be applied in the promotion and development of the world’s most popular sport.

The etymology of the word “stadium” roots back to Ancient Greece. Initially, the Olympic Games consisted of a single event during the course of which Olympic athletes had to sprint along the distances measured in “stadiums” (190±5 m per stadium). Ancient Greek stadiums were built in a bowl-like shape. Each stadium included a field for competitors that was surrounded by earthen embankments that featured spectator seating zones as well as VIP lodges with stone seats. Since then, the design has remained virtually unchanged.

Nevertheless, in the 20th century, architects tried to improve the design of football stadiums and make them more versatile by adding more space between the field and spectator seating zones. On the contrary, 21st-century architects believe that this disengages the fans from the players, reducing the effect of presence. That’s why the official UEFA guidelines for the construction of new football stadiums recommend installing spectator seats as close to the playing field as possible.

Another advantage of building football stadiums besides sports promotion is that the areas in which they are built help to foster sportsmanship and principles of fair play in younger generations. Besides, it facilitates the development of local sports infrastructure and serves as an additional source of income for local businesses.

The creation of a well-designed football stadium replica that also includes the adjacent territory allows to assess the investment potential of a newly built or reconstructed facility, as well as identify all the bottlenecks in advance and reconcile the construction plan with the public. As a rule, the mock-up is placed at the stadium's box office to provide a visual overview of the seating plan.

The architectural modeling of football stadiums is becoming more and more important with each passing year. In the past, however, the stadiums were primarily regarded as engineering constructs with much less focus on aesthetics and appearance. On the contrary, modern architects strive to unite these qualities and build highly functional and beautiful stadiums.

One of the most important parameters of a football stadium is its seating capacity. UEFA recommends designing each and every stadium in a way so the stands are as full and close to the field as possible. This promotes a positive psychological effect on both the players and the fans, and also allows to sell as many tickets as possible. Another thing that should be taken into account is the UEFA and FIFA stadium building guidelines that establish the minimum seating capacity of football stadiums depending on a competition level.

It is also important to have a complete overview of the transport infrastructure surrounding the stadium to assess the level of accessibility to the public and emergency services. The stadium site itself must also have elaborate and simple access routes that connect the site to the main road network.

There’s also the matter of pedestrian accessibility, so the site must feature safe and spacious sidewalks as well as the large adjacent territory that can accommodate a huge amount of people on game days. The routes should provide optimal and easy access to private and public vehicles, including access to cars, train stations, metro, tram and bus stops, cab stands, etc. The fans should be able to enter and leave the stadium in a quick and effortless manner. This once again highlights the importance of a properly designed layout that lets you visually evaluate and assess all of the above-mentioned factors.

The main advantage of using additive manufacturing technologies to create three-dimensional replicas is that they allow for rapid prototyping that turns the expensive manual labor into a cheaper and faster digital production. Although some manual labor, such as assembling, painting, and mounting of lighting elements and mechanics, will still be required, it will be minimal. This approach significantly reduces production time and cost, as well as increases the precision, detalization, and quality of the manufactured part.

You can learn more about the advantages of using additive technologies in 3D prototyping, the specifics of working with Top 3D Shop, as well as specify the production time, the technologies, equipment, and materials we use, and the specifics of the ordering procedure by reading this article.

Source: rjmodels.com.hk

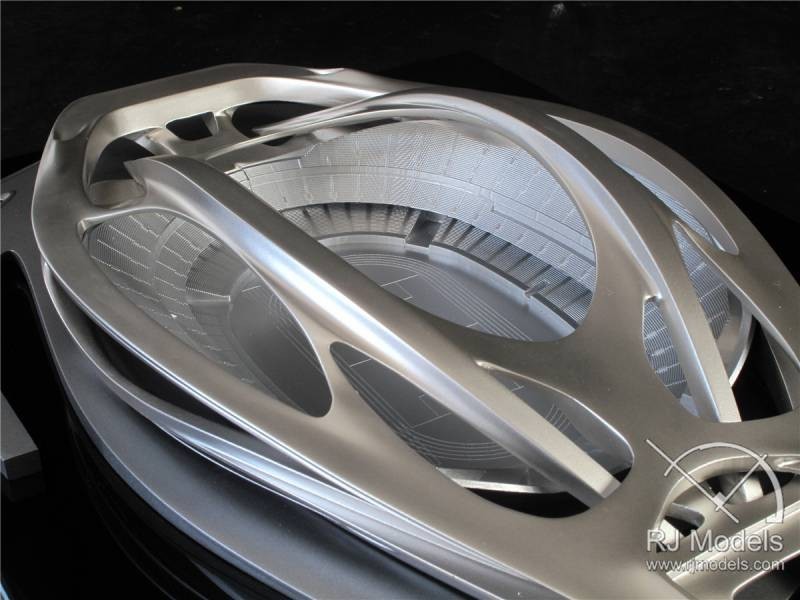

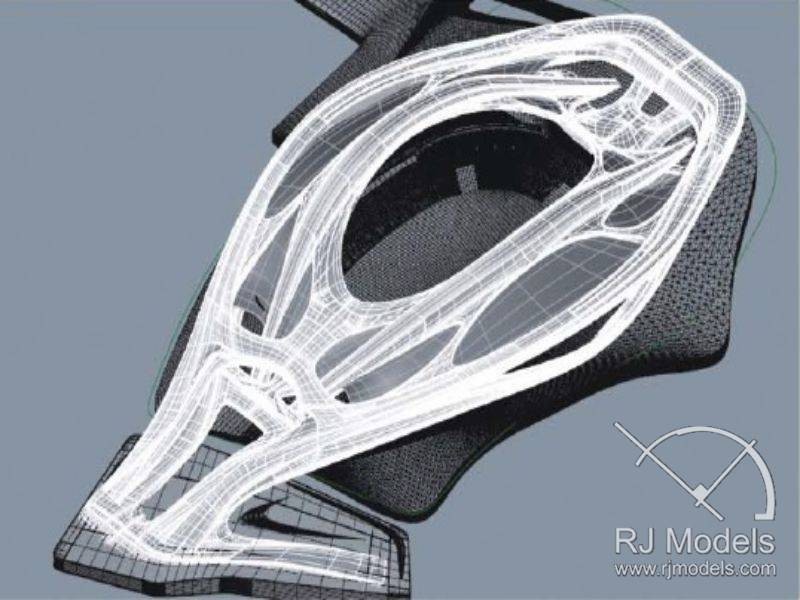

The 80,000-seat bicycle helmet-shaped Tokyo National Stadium project undeniably is an engineering marvel and a vivid example of generative design capabilities. The stadium has virtually no straight lines and was designed by a renowned architecture firm called Zaha Hadid. Although the project won the Tokyo Olympic Stadium design competition in 2020, its construction is still in doubt due to its high estimated construction cost of £1.3 billion.

Source: rjmodels.com.hk

To create an accurate three-dimensional replica of the stadium, Zaha Hadid hired RJ Models, an experienced architectural model making company. The company was provided with not only the drawings of the future stadium but also with the draft sketches of its designs, that is, the outlines that Zaha Hadid architects drew prior to releasing the final version. This was done to convey the ideas that led to the creation of such a design to outsourcers as accurately as possible.

Source: rjmodels.com.hk

Dimension: 500 x 350 mm. Scale: 1:1000.

Source: rjmodels.com.hk

The layout details were 3D printed and painted with metallic paint to convey the intention of the architects in an accurate and precise fashion.

Source: rjmodels.com.hk

The replica took 21 days to be completed.

Source: rjmodels.com.hk

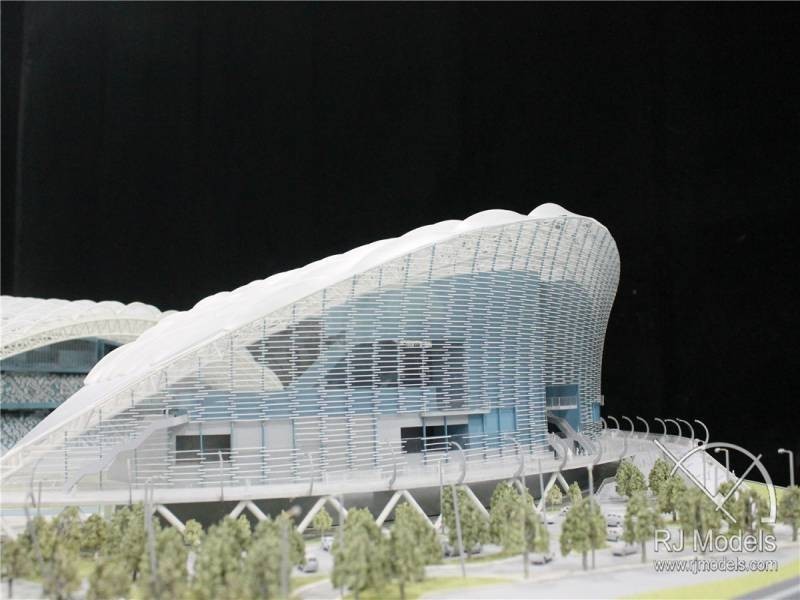

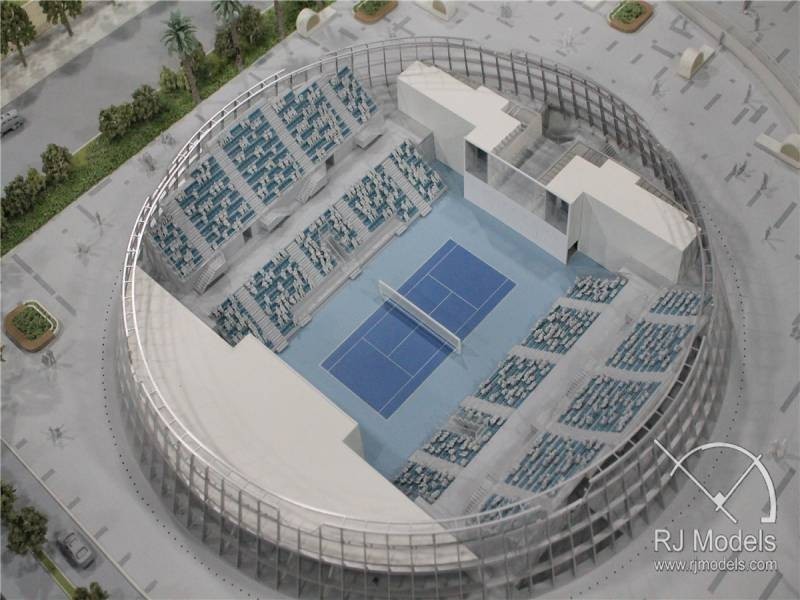

The model of the Sabah al-Salem sports complex of Kuwait University that includes a 15,000-seat football stadium with a tennis court with stands and training fields was created by SOM (Skidmore, Owings & Merrill), one of the largest and most influential architectural companies in the world.

Source: rjmodels.com.hk

The designed football stadium, surrounded by an esplanade with a restaurant and retail outlets, consists of a large soccer field encircled by track and field running tracks with two rooftops over the two main tribunes. It also includes several VIP and training rooms located under the tribunes. All of the above-mentioned elements were also presented on the stadium replica.

Source: rjmodels.com.hk

Dimensions: 2000 x 1850 mm. Scale: 1:500.

Source: rjmodels.com.hk

The company mainly employed laser cutting and 3D printing technologies to create the model. More specifically, laser cutting has been employed to create the field covers and imitate glazing, and the 3D printing helped shape the arched roofs and pillars.

Source: rjmodels.com.hk

The replica was created in just 1 month.

Source: rjmodels.com.hk

A well-detailed mock-up of a futuristic 65,000-seat Abu Dhabi football stadium was created by Mubadala. It shows the original design, the achievable level of spectators convenience during sports events, and the attractiveness of the sports facility for local residents and foreign guests.

Source: rjmodels.com.hk

The main design feature of this football stadium is a huge movable roof intended to protect spectators and players from the sunlight and sandstorms.

Source: rjmodels.com.hk

Dimensions: 2300 x 1600 mm. Scale: 1:150.

The stadium replica, including the movable roof, has been 3D printed according to the customer blueprints. It also features some laser engraved parts. All of the flat elements were laser cut. There is also the LED lighting system that provides access to the insides of the roof structure and gives the layout a more realistic look.

The mock-up was completed in one month.

Source: rjmodels.com.hk

Source: rjmodels.com.hk

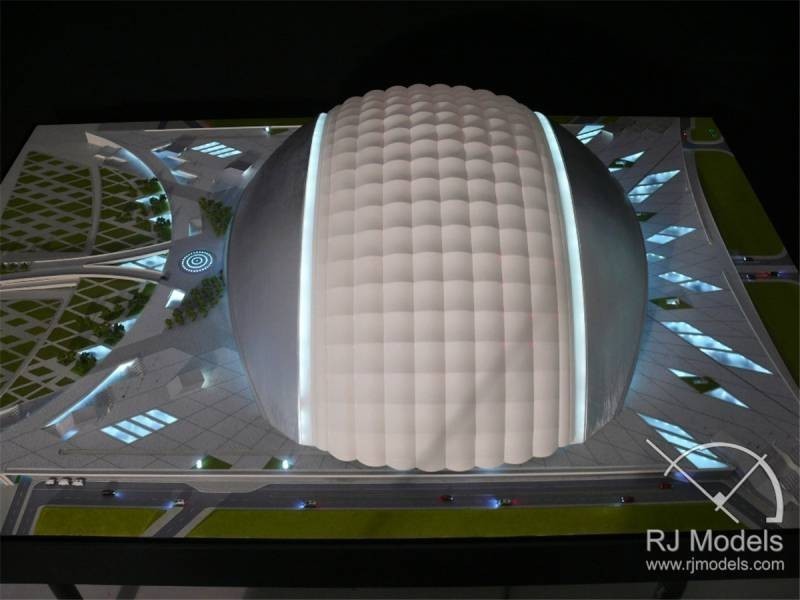

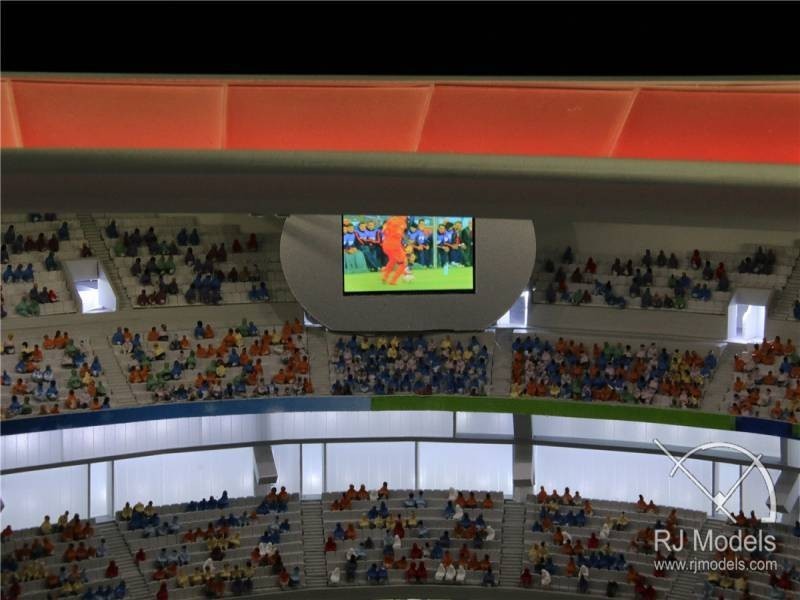

The replica of the 60,000-seater football stadium that was built to host the 2019 Asian Cup and other important international sporting events for the country, had become the first and largest fully air-conditioned stadium in the UAE. The mock-up shows all the additional infrastructure of the sports complex including the adjacent territory with transport interchanges.

Source: rjmodels.com.hk

The RTA has commissioned RJ Models and 3DR Models architectural companies to create two three-dimensional replicas of the stadium at different scales. Towering above the ground in the form of a hemisphere that expands upward (bowl-like design), the stadium has been recreated in a highly precise and accurate fashion. The replicas also include a parking lot, training grounds, road junctions, and a lighting system.

Source: rjmodels.com.hk

The main feature of this project is that it was implemented in two versions. There is a large model with outer dimensions of 2800 x 1500 mm that was made in the 1:250 scale that features all the adjacent infrastructure, and a more compact yet more detailed model of the stadium itself with a scale of 1:250 and outer dimensions of 1500 x 1500 mm.

Source: rjmodels.com.hk

This particular project was completed by 3D printing most of the details. The facade of the building was made using laser engraving to convey the texture design conceived by the architects in the most accurate fashion possible. There are also several thousand spectator figurines in the stands. The separate design of the lighting systems both inside and outside the stadium allowed the client to demonstrate different lighting options for the site. The stadium model is mounted on a stable MDF base and can be easily transported.

Source: rjmodels.com.hk

Each replica was completed in less than one month.

Timur Aliyev, Top 3D Shop service department specialist

Each football stadium replica should include its large and flat interior areas, all the external parts, and an imitation of the stadium surroundings. Architectural models, construction drawings and photographs are used as the basis to create a precise 3D model of the future layout. On a scale matter, the 1:150 and 1:200 are the most commonly used scales for creating stadium layouts, as they let you show and highlight even the smallest yet very important details, such as spectator areas, seatings, and fence elements.

The creation of a neatly looking and highly precise football stadium mock-up requires the most advanced manufacturing techniques. We prefer using rapid prototyping through photopolymer printing, laser cutting, engraving, and CNC milling to create most of the stadium layout designs.

The material choice depends on the project specifics. It may feature wood, paper, and metal-made parts, as well as plastic and photopolymer resins-printed details.

Football fields and stadiums are the heart of the most popular professional game in the world. Each stadium is a place where the history of sports is made. The fact that high-quality stadium design is vital to the comfort and safety of spectators, players, officials, media and the staff is undeniable. The architectural design of football stadiums must meet very high standards, both technologically and aesthetically, as they become the main points of attraction for both locals and foreigners. Moreover, football stadiums are an inseparable part of public life and are the engine of local businesses.

It is impossible to assess the capabilities of existing football arenas and the prospects of building new ones without creating their well-detailed three-dimensional replicas in the first place. The stadium design should take into account not only the current needs but also the possibility of an expansion in the future, since every stadium may require different improvements such as the installation of additional structures (for example, roofs) and additional buildings like hotels, parking lots and shopping centers.

Update your browser to view this website correctly. Update my browser now

Write a comment