Hey everyone! In this review, we will tell you about the UP300 personal FDM 3D printer by the renowned Chinese manufacturer Tiertime. Explore the capabilities and design features of the device as well as differences from previous models.

The Tiertime UP300 is a typical out-of-the-box 3D printer. The build volume of the device is 205 x 255 x 225 mm — not very large but enough to print objects with the area of an A4 sheet. Like the entire Tiertime line, the UP300 is designed for printing ABS and other medium-temperature materials such as HIPS. However, the included replaceable extruders also allow employing flexible materials and low-temperature filaments or those with high fluidity. With the emphasis on the use of ABS plastic, the model has a perforated print bed to increase adhesion. Numerous smart features such as Wi-Fi connectivity and interchangeable heated boards make for the wide functionality and high performance of the device.

The printer comes with the following set of items:

Also, the package contains three different print heads — for TPU, ABS, and PLA.

The Tiertime UP300 features an attractive finish made of black matte plastic, which harmonizes with the tinted glass of the chamber door. The touchscreen is located on a special pedestal on the right, under which there is a USB connector.

The right side houses a compartment for the filament spool. The UP300 is a single extrusion 3D printer, so there is only one niche. The compartment has a magnetic door lock on the left and a material feed chute on the right.

On the back wall, there is a niche with connectors and a power switch.

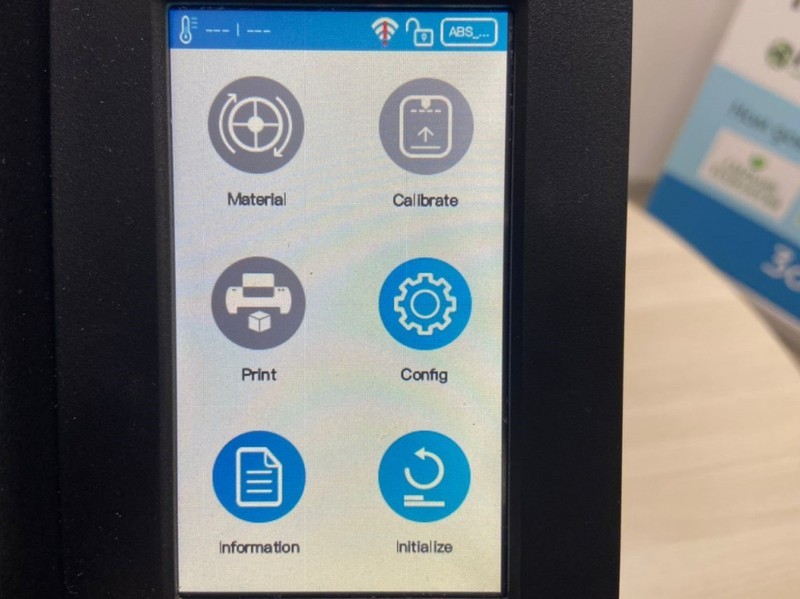

The main menu of the printer contains five sections and one initialization button, that is, connecting the printer to the slicer and turning on all on-board systems including fans.

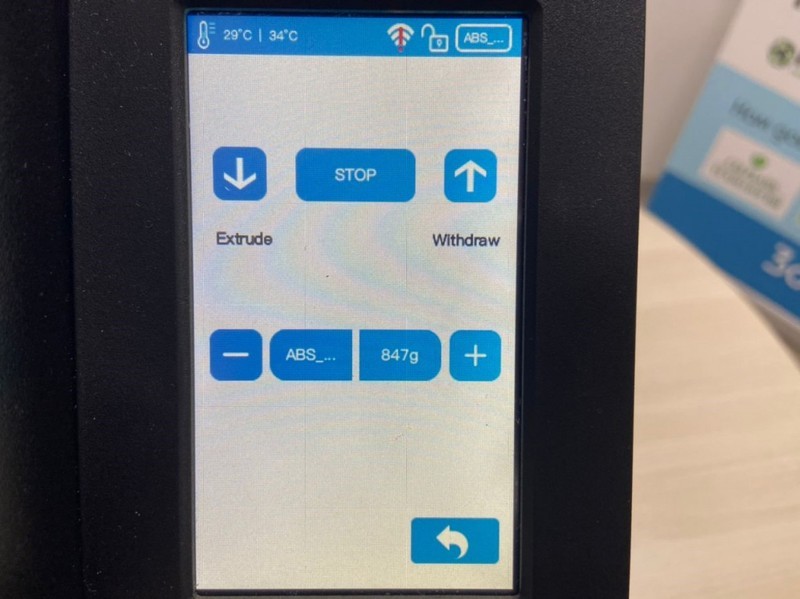

In the Material menu, the user can extrude or withdraw the filament. You can monitor the remaining weight on your own or through the slicer interface. It should be noted that the choice of the type of material works only in the slicer; on the display, this information is purely for informational purposes. The UP300 has no temperature profiles.

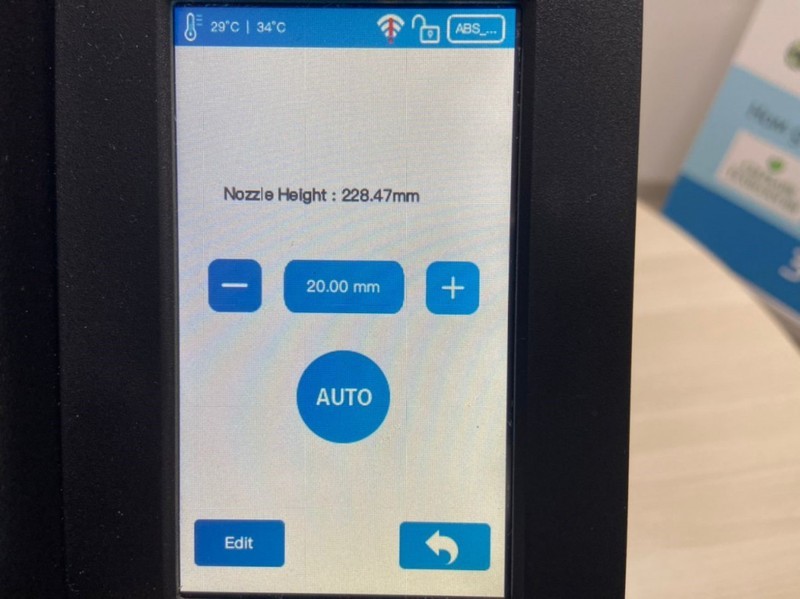

The Calibrate menu offers a bed leveling that is familiar to those who have dealt with the company's previous models. After performing auto calibration, when the printer corrects the plane of the bed with a retractable probe, we need to set the gap between the nozzle and the bed using a special sensor.

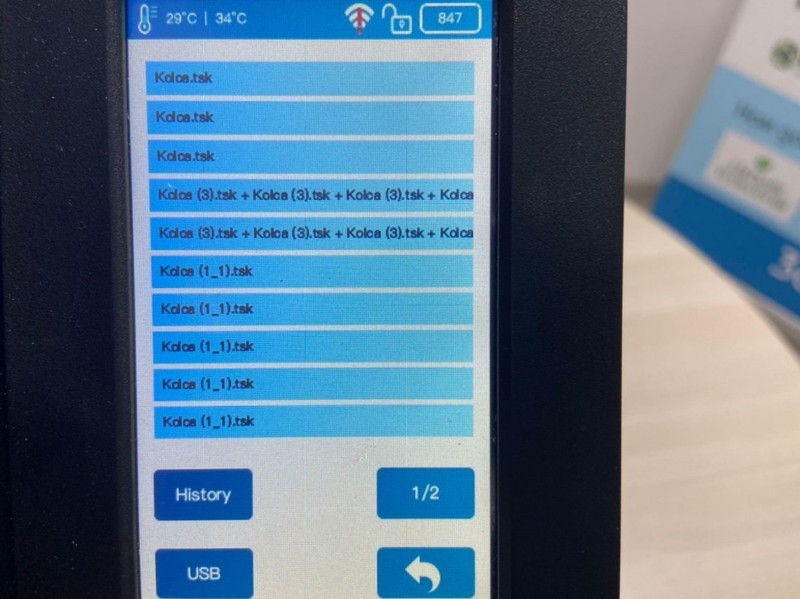

The Print menu allows viewing files in the device's on-board memory, or on a USB flash drive if one is installed. Files are transferred via USB cable, Ethernet, or Wi-FI connection.

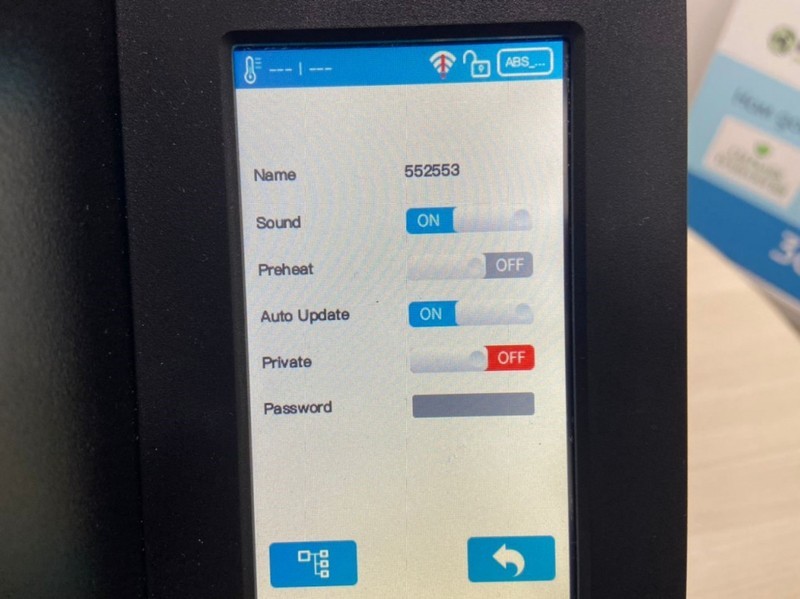

The Config menu allows you to enable or disable various functions and configure the network settings.

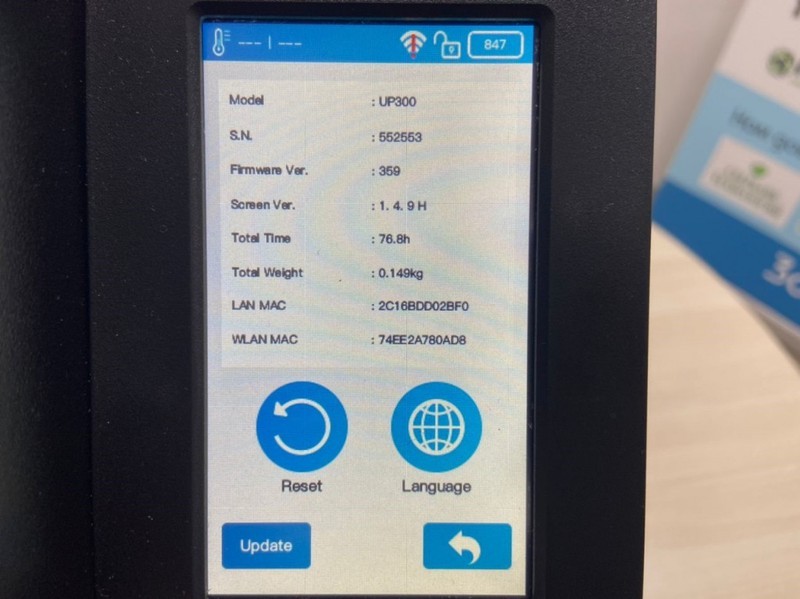

The last section contains service information and firmware reset or update buttons, as well as the choice of the language — Chinese or English.

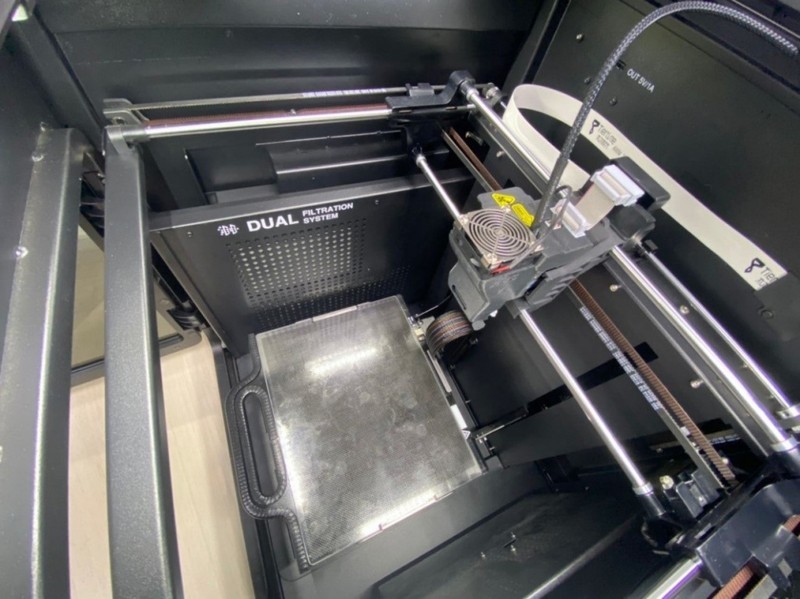

The printer features a metal frame in a plastic casing, the kinematics is attached to the metal part, with the mechanism of the print bed covered with a metal wall.

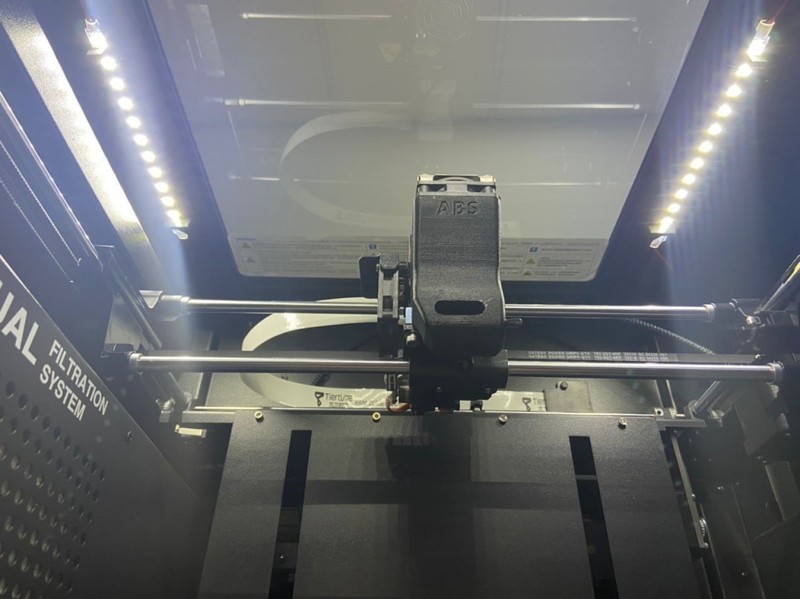

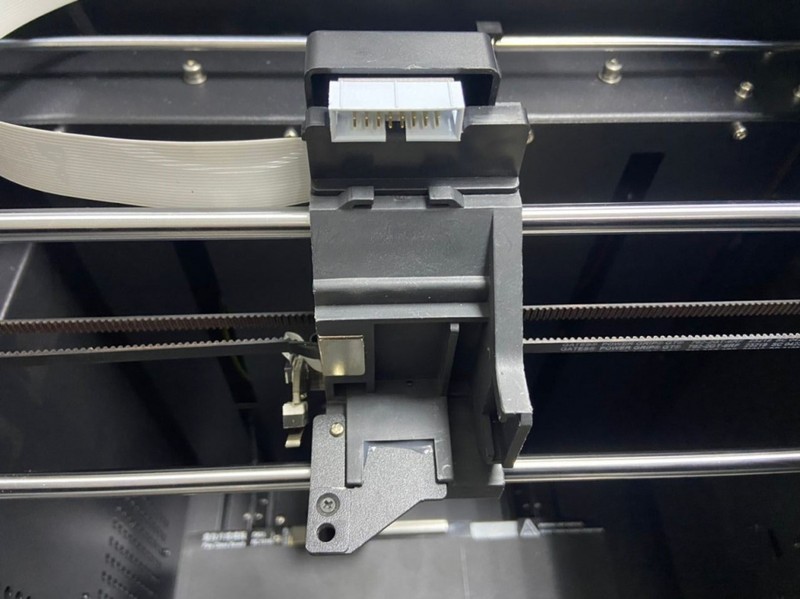

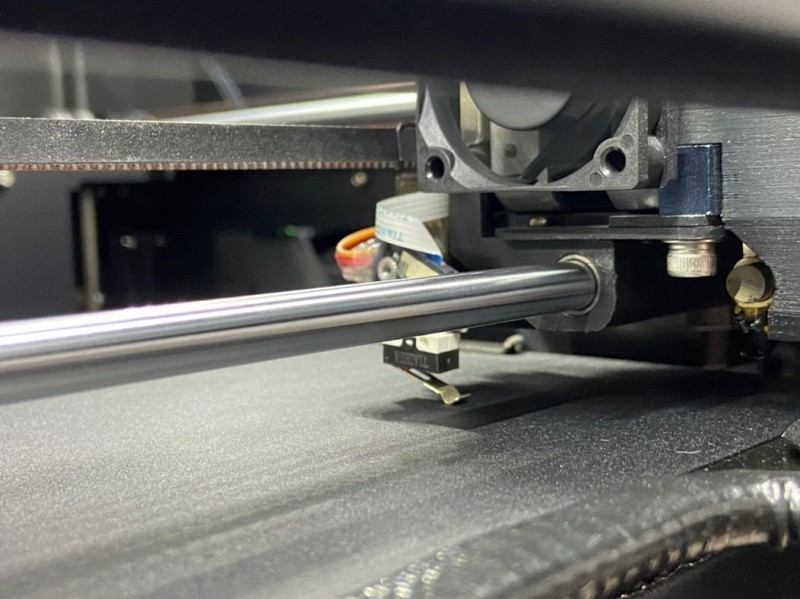

The kinematic scheme of the printer represents one motor per axis and cylindrical guides; the carriage of the print unit is installed at an angle, which adds rigidity to the structure.

The body also has a dual HEPA filtration system, which is installed between the casing and the metal frame on the right side.

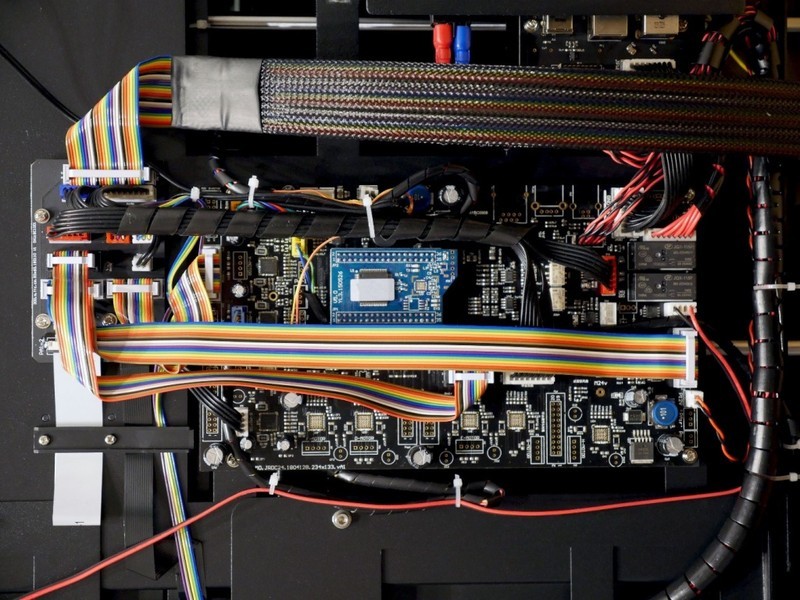

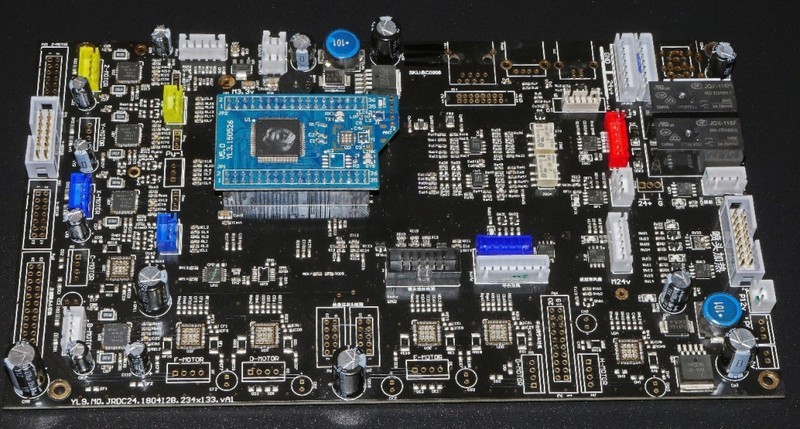

The printer adopts a control board of the proprietary design and production. The system is based on an ARM Cortex controller soldered on a separate unit for easy replacement if necessary.

Axis drivers are soldered on the board itself without the possibility of replacement or adjustment, the firmware also has a closed architecture and does not allow editing.

The Wi-Fi module is soldered on the board, too. The power supply unit is external — 220 volts.

Another USB connector is located inside the build chamber. It is not entirely clear why it is needed there. It may be used as a power source for a web camera, for instance.

The printing area is illuminated by LED lighting. When opening the front door, the limit switch is triggered and the device goes into pause mode.

The print unit is based on the design of the very first Tiertime solutions. Its printing temperature is up to 300 degrees, which means the range of materials to be used is quite wide. However, the heated bed reaches only 100 degrees, and this might not be enough for some particularly capricious plastics with high shrinkage.

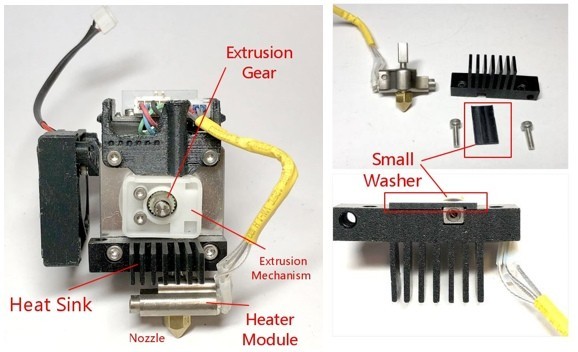

The design of the unit is straightforward: an extrusion gear attached to the stepper motor, a feed tube, heat sink, extruder tube with a coldend, and hotend. Simple as it is, this scheme completely copes with its task — clogging and other problems inherent in such mechanisms are very rare. The hotend has replaceable nozzles — the set comes with brass ones of 0.2, 0.4, and 0.6 mm. Also compatible are nozzles made of wear-resistant steel and even ruby ones for printing with highly abrasive composite materials.

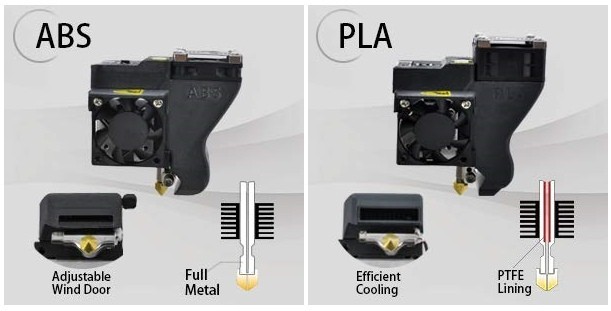

According to the official guide on the manufacturer's website, ABS and PLA extruders differ in the presence/absence of a Teflon tube. No other changes have been declared, but from experience, we can say that when the device detects the PLA extruder, the heating slightly decreases and the fans spin at higher speeds.

The TPU extruder has a continuous tube of the feed mechanism to avoid breakage and jam.

The print head is attached to the carriage with a magnet and can be conveniently replaced with another — all you need to do is plug the ribbon cable into the connector.

The unit also has a servo-driven inductive sensor, which plays the role of a probe during bed leveling.

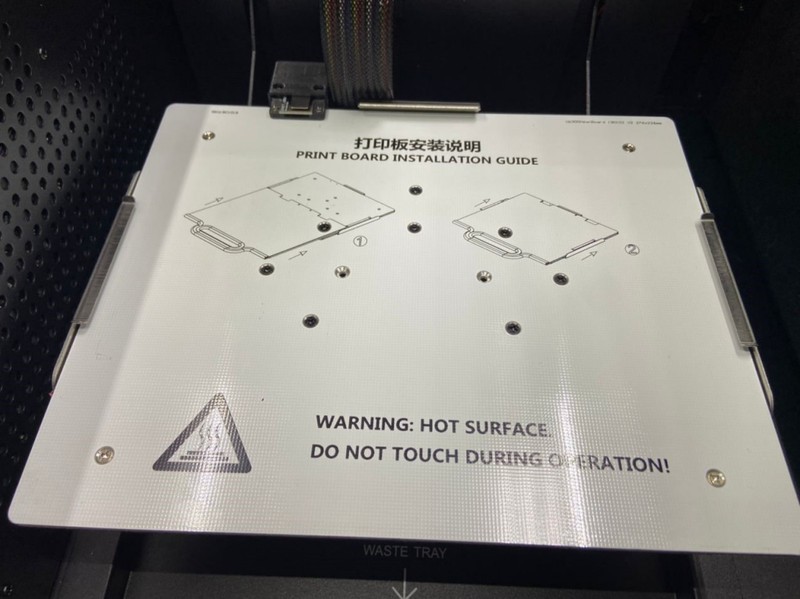

The printer comes with two double-sided adhesive plates: Perf and Flex. The former has a perforated layer on one side and a glass surface on the other, while Flex benefits from a smooth surface for printing PLA-type material without a raft, with the backside being of glass as well. This provides either maximum material pressure and printing on a raft or a smooth first layer on glass.

The bed heater is soldered in the form of a board with an integrated temperature sensor. At the top left, there is an additional zero sensor, which is touched by the nozzle during calibration.

There is no mechanical leveling, the plane is set at the factory. It is only necessary to perform a 9-point correction and an additional test of the nozzle height. Calibration should be done if the extruder or nozzle is replaced.

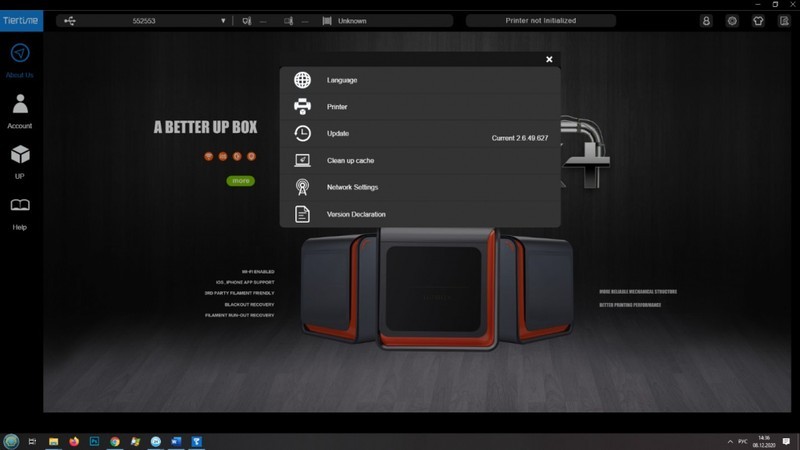

The Tiertime UP300 uses the fourth version of the UP Studio software. The program is intended to be simple and user-friendly for beginners, so it does not provide a huge number of settings. Yet, the set of existing ones is quite enough for quality results.

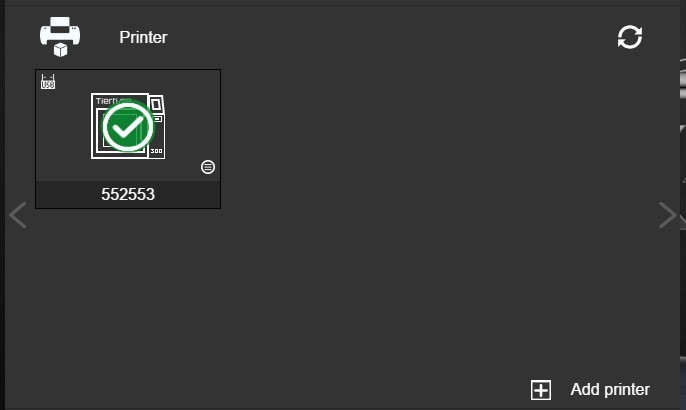

When turned on for the first time, the program will detect the device automatically, if the printer is connected via Wi-Fi.

In our case, the device is connected via USB. The slicer can connect to only one specific device at a time but “see” many of them via Wi-Fi or Ethernet. This allows you to organize such devices into a cluster and make a 3D printing farm of them.

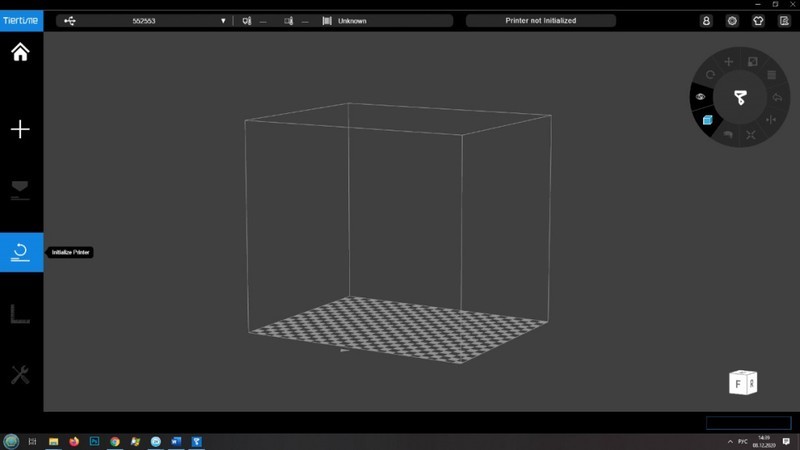

The interface is quite intuitive — on the left, there are four main sections: print settings, initialization, calibration, and service; on the right is model management, which involves placement, size, rotation, etc.

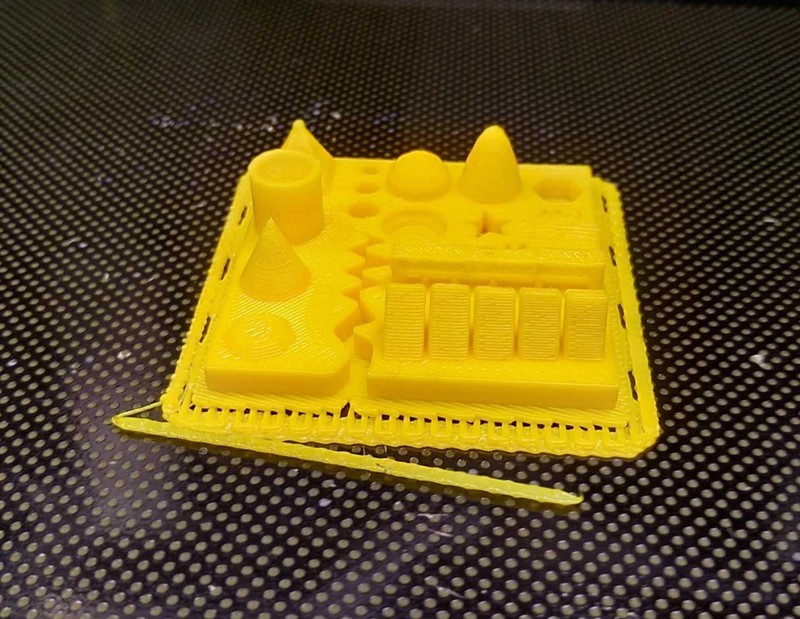

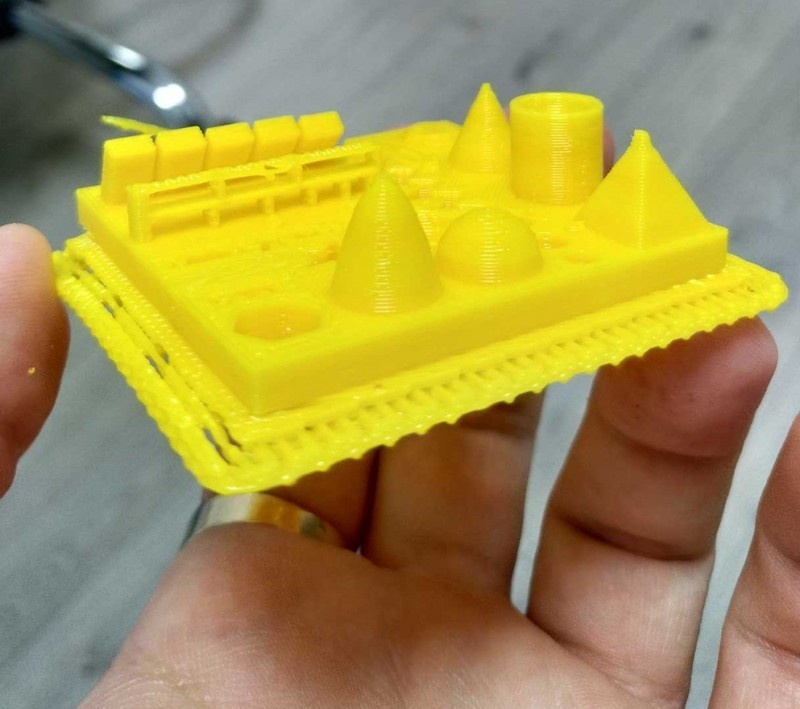

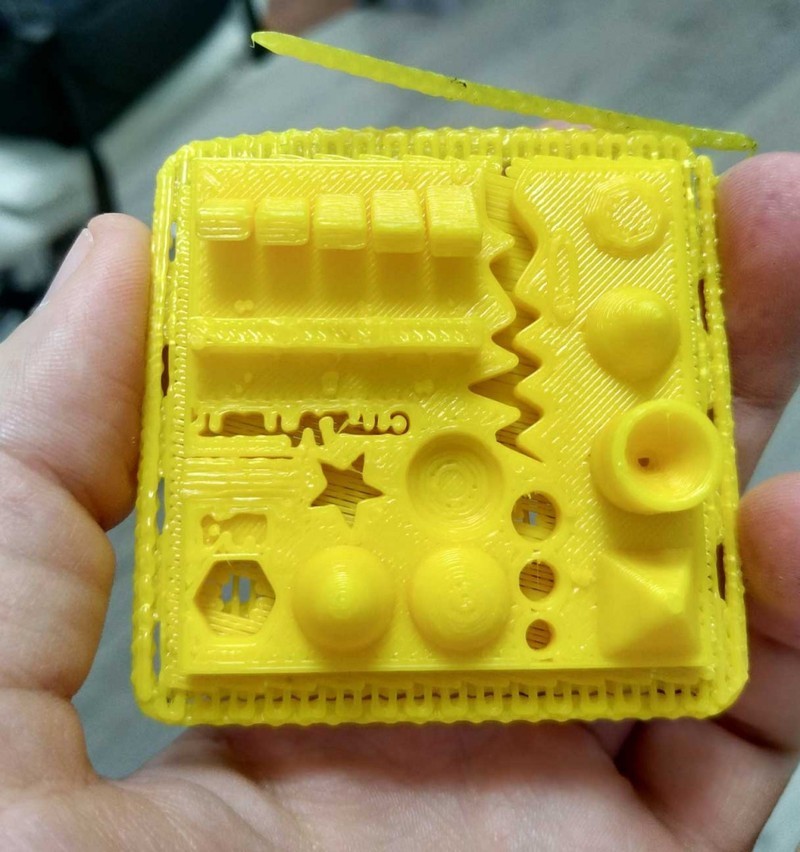

As a result, we got the following test model. We used yellow ABS by E-Sun, 0.6 mm nozzle, 0.2 mm layer thickness.

The Tiertime brand is primarily known for the ease of use, repeatability, and reliability of its products, as is clearly seen in the case of the UP300 model. The printer will perfectly fit into a workshop or laboratory and can become an indispensable assistant in production or an excellent gift for a hobbyist. Thanks to the convenient interchangeable beds, the updated UP! Studio slicer, reliable electronics based on Arm Cortex controllers, and other important features, the UP300 is a complete solution with all the advantages of its predecessors.

Update your browser to view this website correctly. Update my browser now

Write a comment