Creality is a global pioneer in 3D printing that has long been known for its wide range of consumer-oriented desktop devices. Recently, the company has ventured into the professional 3D printing market, which definitely takes its affordable, high-performance devices to the next quality level.

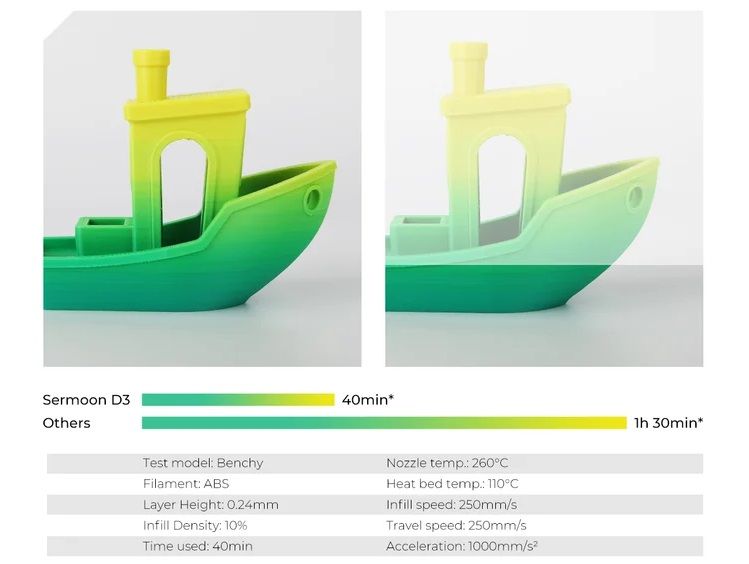

The Sermoon D3 is a newly announced professional FDM 3D printer tailored for industrial applications that offers an intuitive solution for prototyping, jigs and fixtures making, design verification, and more. It boasts increased printing stability and operation reliability alongside high-temp capabilities, impressive speed, and advanced controls. Sounds like a perfect device for cost-effective small-batch production, but what else does it have to offer?

This is Top 3D Shop, and today we will take a closer look at the Creality’s latest addition to their industrial-grade series — Sermoon D3. Let’s find out its technical peculiarities and spheres of application.

Coming from the engineering-grade series, the Sermoon D3 introduces a number of features appealing primarily to industrial designers and manufacturers. The machine is designed with a large build volume and sturdy components to meet the needs of small-batch production, while also providing high accuracy, speed, and reliability of printing. In combination with advanced software functions, one can safely say that the Sermoon D3 is designed to boost R&D efficiency, cut manufacturing costs, and reduce the production cycle.

The Creality Sermoon D3 possess the following characteristics:

Before you start printing with the Sermoon D3, the machine should be properly unpacked and set up.

The printer is supplied fully assembled in a large cardboard box. First, cut the straps and remove the cover and sleeve.

On top of the package, you will find a layer of protective foam.

Then, it is time to take the device out of the box. It might take two people since the printer should be handled with care.

Once the machine is installed on the desktop, carefully remove the Y-axis belt clip.

To take out the protective foam from the inside, slide the printhead aside.

Then, you can remove the X-axis belt clip as well.

To make sure the printhead operates well, just move it around a bit.

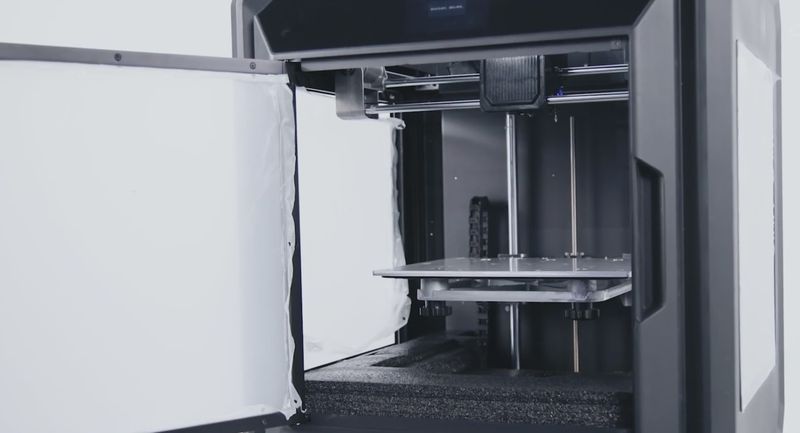

Finally, take out the enclosure and protective foam from the printer’s chamber.

You can find the full packing list on the Sermoon D3’s product page.

Now, when the Sermoon D3 is unpacked, let’s get to its preparation for printing starting with the basics.

First, plug in the power cord and flip the switch to turn on the machine.

Select a language and follow the instructions displayed on the screen.

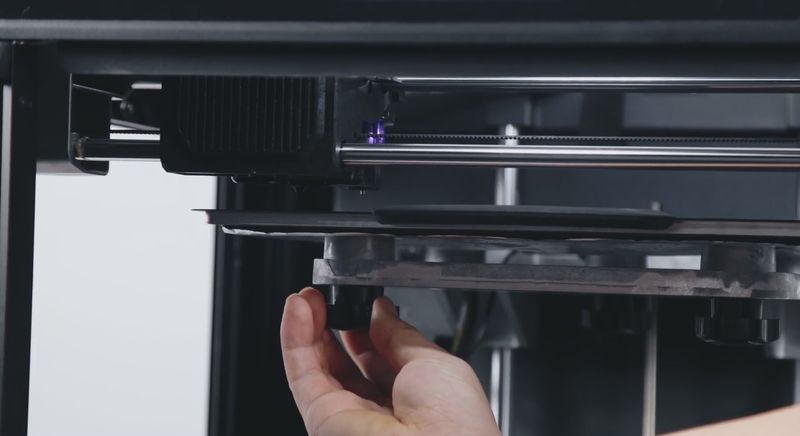

To continue with setting, the heatbed should be lifted to remove the remaining cushion foam.

Once this is done, you will see a welcome message, and the heatbed will automatically return to its original position.

Now, it is time to proceed with unwrapping. Remove all the remaining protective film: it will not be needed anymore.

Finally, do not forget to remove the protective cover from the camera.

With that done, the printer is ready for the calibration process.

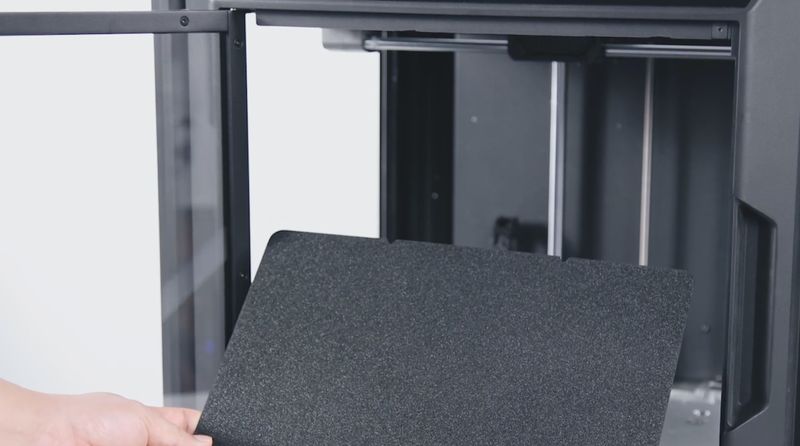

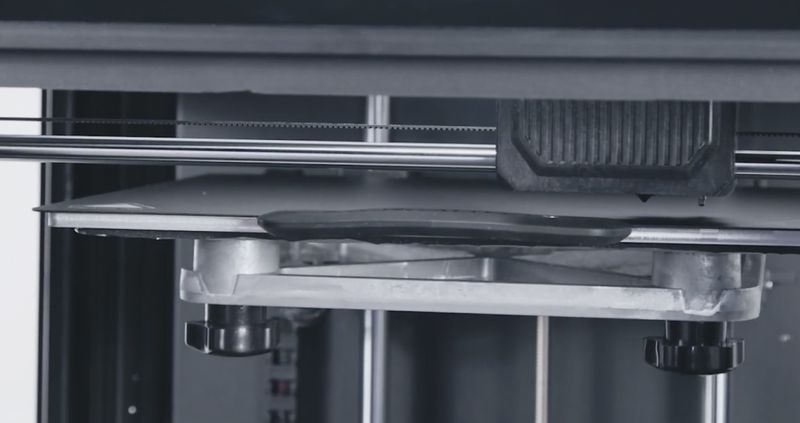

Before calibration, it is important to ensure that the platform and automatic Z-offset module are clean. When they are, securely set the build surface on the heatbed.

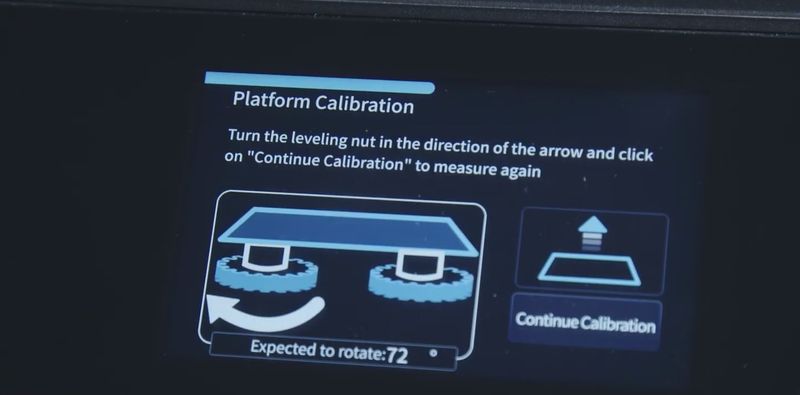

The printer will provide guidance on the further calibration. The steps are pretty clear and straightforward, so it is enough to follow them.

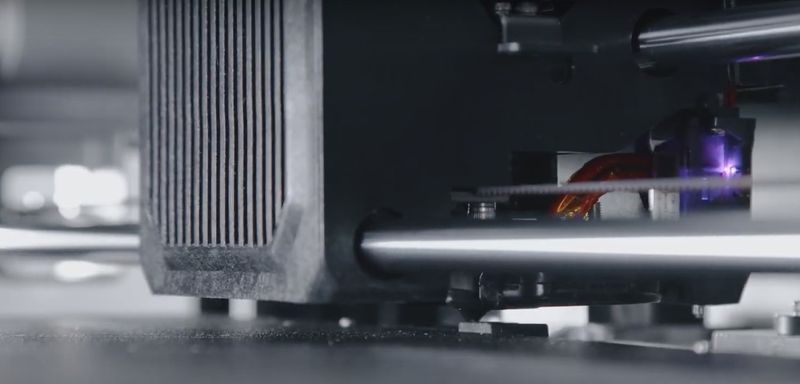

Mostly, the system will manage on its own due to the Creality’s CR Touch auto-leveling technology.

Just wait until the leveling process is complete.

To begin with the next step, one needs to install the teflon tube supplied with the printer.

Do not forget to fix it with the help of the dedicated mounts to ensure smooth and consistent material extrusion.

Then, attach the spool on the holder and load filament into the extruder through the tube.

When the filament starts flowing out of the nozzle, loading is finished.

If you are going to use flexible filaments like TPU, it is recommended to install the external material rack supplied with the device. It is extremely easy to assemble and mount.

The feeding process here will be just the same.

Also, do not forget to use the enclosure while printing with ABS, ASA, and other high-temp filaments.

One of the Sermoon D3’s main advantages is its flexible system that allows printing 3D models in several convenient ways.

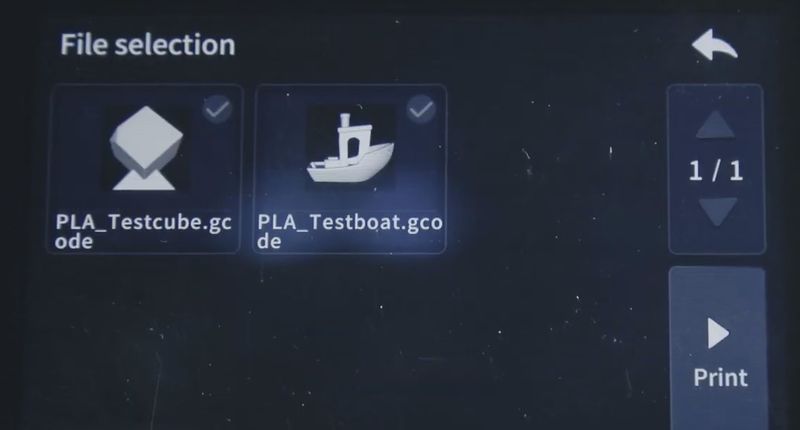

For example, the user can simply pick a file on a USB drive and print it right away.

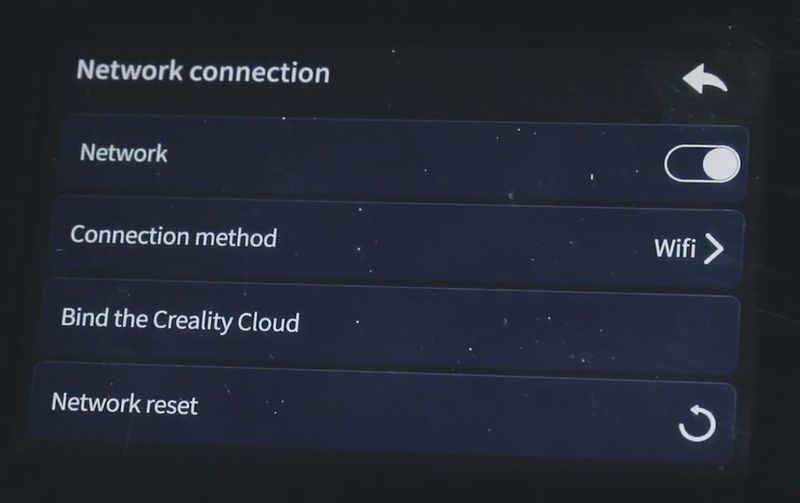

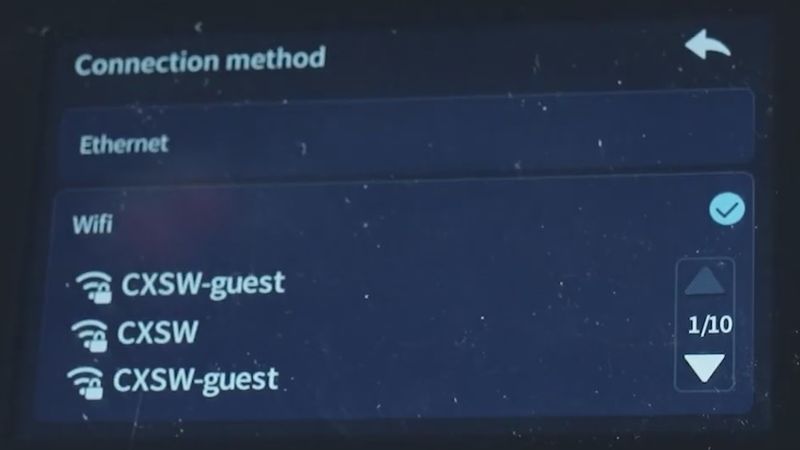

LAN and Wi-Fi methods require network connection. To configure it, go to the Print Setup menu.

Depending on the mode chosen, plug in the RJ45 cable for the Ethernet option...

...or simply connect to a suitable Wi-Fi network.

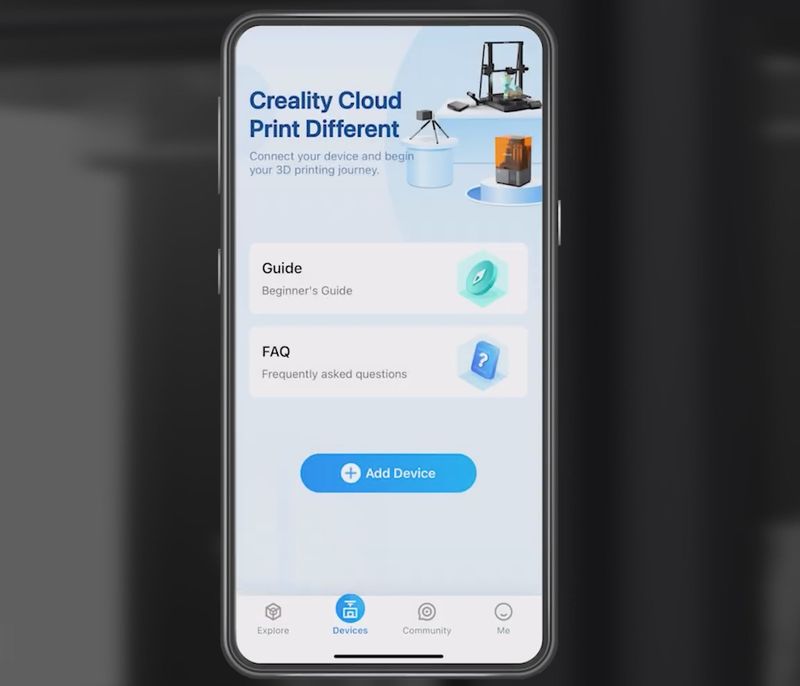

Another handy variant is cloud printing available with the company’s self-developed mobile app.

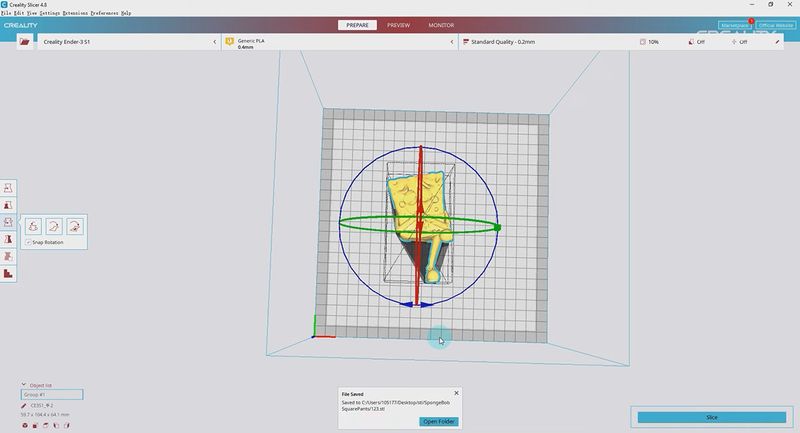

In terms of software, the Sermoon D3 model works with the proprietary Creality Print slicer and Creality Cloud technology. They represent an ultimate easy-to-use tool for complete control over the printing process. The slicer allows one to conduct various operations with 3D models, from searching and uploading to full-fledged editing. Apart from traditional functions, Creality Print offers one-click model slicing, auto-leveling, real-time model preview through the integrated HD camera, and remote control for a streamlined user-friendly experience.

Both programs work with commonly used STL, OBJ, and 3MF file formats. The Creality Print FDM slicer is available for free on PC for Windows (64-bit only), macOS, and Linux. As for Creality Cloud, the application is supported by Android and iOS.

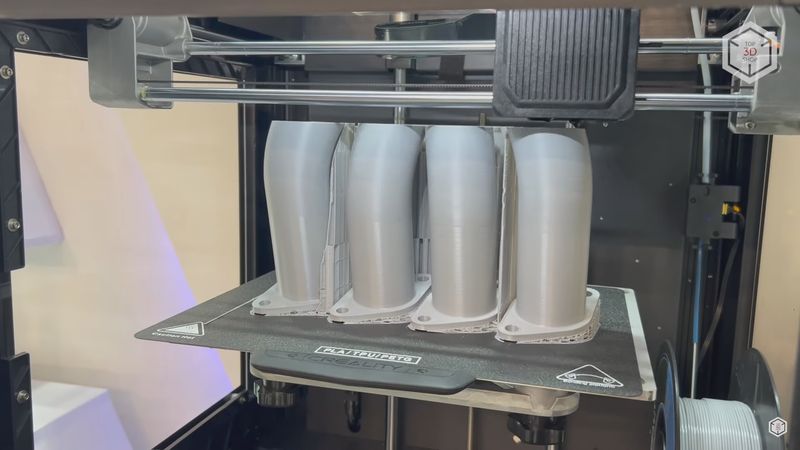

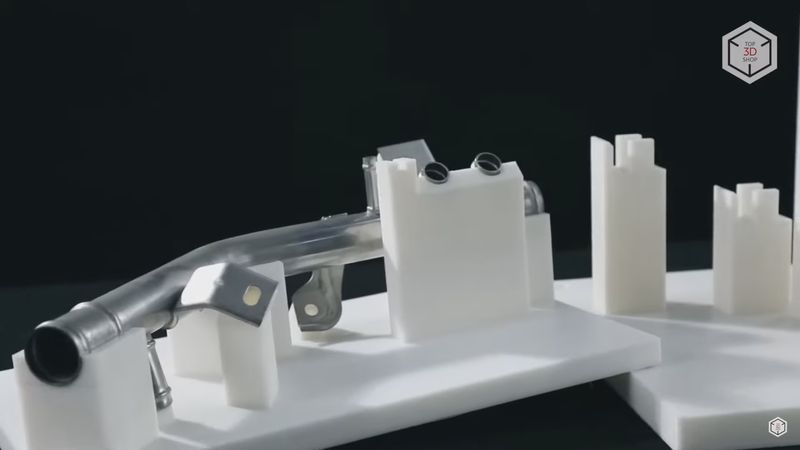

The Creality Sermoon D3 3D printer is designed with stability and efficiency in mind. Being a reliable, precise, and high-speed machine, it will serve as a perfect device for prototyping, jigs and fixtures making, design modification, education and research, small-batch orders, mass production of oddly shaped parts and products, etc.

Check out these complex technical parts made from different materials to demonstrate the printer’s precision capabilities:

As for modeling and prototyping, the Sermoon D3 also performs well with various custom designs:

Credit: @3dg_nz / Instagram

Credit: @locallyprint3d / Instagram

The Creality Sermoon D3 is a high-end professional 3D printer built to current industry standards. From strong constituent elements to convenient modern features like cloud printing, everything about this device would suffice professional designers and manufacturers.

Despite its relatively high price (compared to other Creality offers), which is nevertheless justified by the complete package, this fully enclosed and ready-to-use machine provides high accuracy, printing consistency, expanded functionality and connectivity fit for a wide range of applications, including small batch production and much more.

Update your browser to view this website correctly. Update my browser now

Write a comment