Hello and welcome to Top 3D Blog. This time, we are going to tell you everything there is to know about the RangeVision Pro series — a lineup of precise Russian-made 3D scanners that can accurately capture every inch of any object and create its 3D model in the blink of an eye. As always, we are going to give you an in-depth overview of the devices’ functionality, as well as show some of the use cases. Continue reading to learn more.

Source: 3dnatives.com

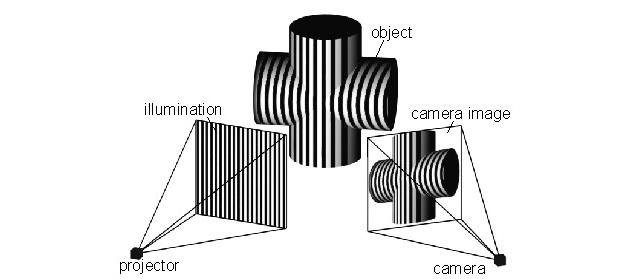

First, let’s quickly recap how structured light 3D scanners operate.

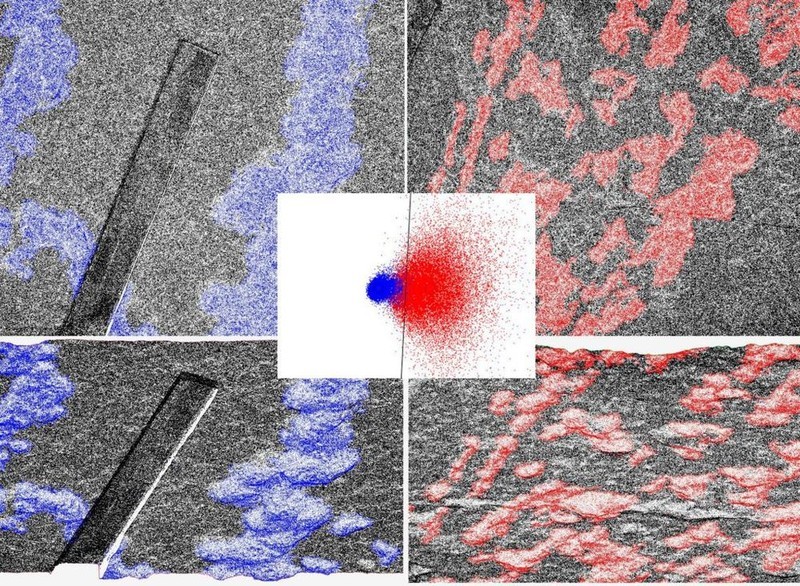

As a structured light 3D scanner enters the scanning mode, it projects a high-contrast monochrome pattern onto the surface of a scanned object, which then gets distorted by the object’s shape. After receiving enough information, the scanner recreates the object’s shape, surface, and position in space based on the distortions data, providing you with a high-precision 3D scan.

In case the scanned object’s surface is transparent, shiny, or too dark, it has to be applied with a special matte spray to help the scanner create an accurate three-dimensional representation since such objects are significantly more challenging to scan.

Source: 3dprint.com

RangeVision is an experienced and trusted developer of high-quality structured light 3D scanners. Founded in 2010, the company is represented by a team of passionate and dedicated individuals that foster and promote innovations in their respective fields. The offered lineup consists of high-end multifunctional 3D scanners that provide the highest level of detail, accuracy, and capturing speed due to the unique data processing algorithms.

“The user can choose the appropriate device depending on the requirements and project specifics”, — explains Yuri Chaikin, RangeVision’s founder and CEO. “All the scanners come factory-calibrated, which guarantees excellent results and allows using them right out of the box.”.

Source: rangevision.com

The RangeVision lineup consists of several 3D scanner families, namely: Pro, Spectrum, and Neo.

Source: rangevision.com

The RangeVision Pro family is represented by 3D scanners with exchangeable optics. Therefore, the user has the ability to configure the device depending on the dimensions of a scanned object, allowing for hassle-free scanning of both tiny (< 3 cm) and large (> 1 m) objects. The main difference between RangeVision Pro models lies in camera resolution: 3MPX and 6MPX for PRO base and PRO respectively.

Source: rangevision.com

The RangeVision Spectrum family is represented by professional desktop 3D scanners that employ industrial 3.1 MPX cameras and feature three different scan modes to provide astonishingly precise renders of objects of almost any size and shape.

Source: rangevision.com

Designed for entry-level users, RangeVision Neo comes with an automatic turntable, tripod, and dedicated software solution. It is a lightweight and easy to use a device that requires a PC connection and weighs just 1kg.

Source: picpanzee.com

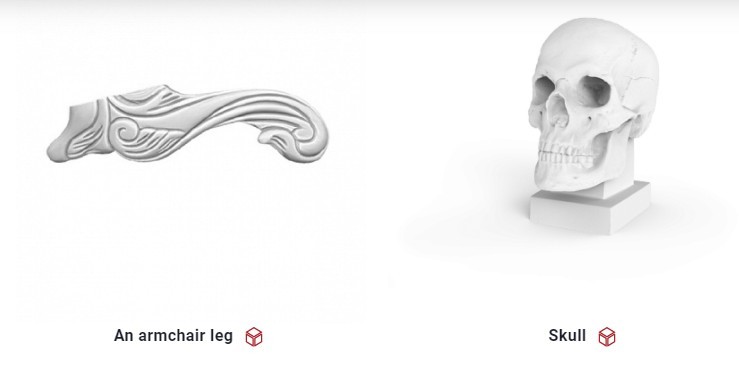

Capable of delivering high-precision scans no matter the complexity in a flash, the RangeVision Pro 3D scanners are used in a plethora of professional applications including manufacturing, design, reverse engineering, quality control, jewelry, art, education, science, and cultural heritage preservation.

The devices are equipped with high-resolution cameras, allowing to create astonishingly precise (up to 0.018mm) renders. Currently, the RangeVision Pro lineup is represented by a duo of powerful 3D scanners: the RangeVision Pro (successor of the RangeVision Pro 5М) that features industrial-grade 6MPX cameras, and the RangeVision Pro Base (successor of the RangeVision Pro 2М) that offers a slightly lower camera resolution of 3MPX.

|

Model |

||||||

|

Projector resolution |

FullHD |

FullHD |

||||

|

Camera resolution |

3 MP |

6 MP |

||||

|

Price |

||||||

|

FOV |

L |

M |

S |

L |

M |

S |

|

Working distance, m |

0.9 |

0.52 |

0.26 |

0.9 |

0.52 |

0.35 |

|

FOV size, mm |

520х390х360 |

280х210х200 |

115х85х80 |

550х340х360 |

320х210х200 |

140х90х80 |

|

3D resolution, mm |

0.25 |

0.13 |

0.05 |

0.18 |

0.10 |

0.04 |

|

Accuracy, mm |

0.06 |

0.03 |

0.018 |

0.06 |

0.03 |

0.018 |

|

Maximum permissible error, +/- microns |

n/a |

80 |

60 |

40 |

||

|

Dimensions, mm |

408х350х125 |

|||||

|

File formats |

STL, OBJ, PLY |

|||||

|

Scanning technology |

Structured light |

|||||

|

Weight |

6.5 kg |

|||||

|

Power |

100 — 230 V |

|||||

|

System requirements |

OS: Windows 7/8.1/10 64bit; CPU: Intel Core i5/i7 (Broadwell or better); GPU: Video card GeForce 960 series or better; RAM: at least 16 GB; Other: two USB 3.0 ports |

|||||

Source: rangevision.com

Each of the RangeVision Pro 3D scanners is shipped with:

Scanning module with cameras and a LED projector

Exchangeable optics for each FOV

Plastic case for storage and transportation

Tripod

Software solution and a license key

Markers (reference points)

Matte spray to scan transparent, shiny, and dark objects

Host PC

Set of power and connection cables

Source: rangevision.com

Source: rangevision.com

An automatic turntable is an indispensable tool for automatic 3D scanning. Depending on the application, you can opt for the TS model (capacity: 20 kg, platform diameter: 20 cm) or choose its TS counterpart (capacity: 60 kg, platform diameter: 20 cm). The turntable must be connected to the host PC via a USB port and to the 110-220V power source via an adapter.

Source: rangevision.com

Designed to provide the utmost level of convenience and safety during transportation, the protective case is a more reliable and suitable version of its stock counterpart.

Source: rangevision.com

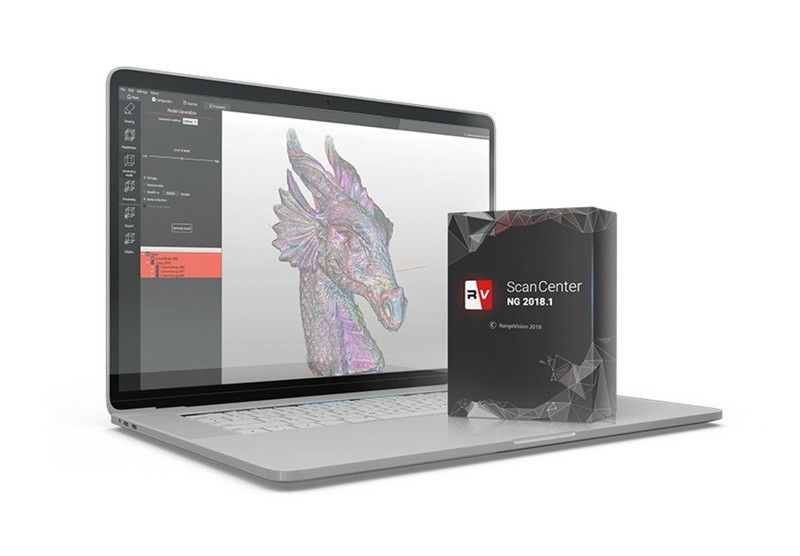

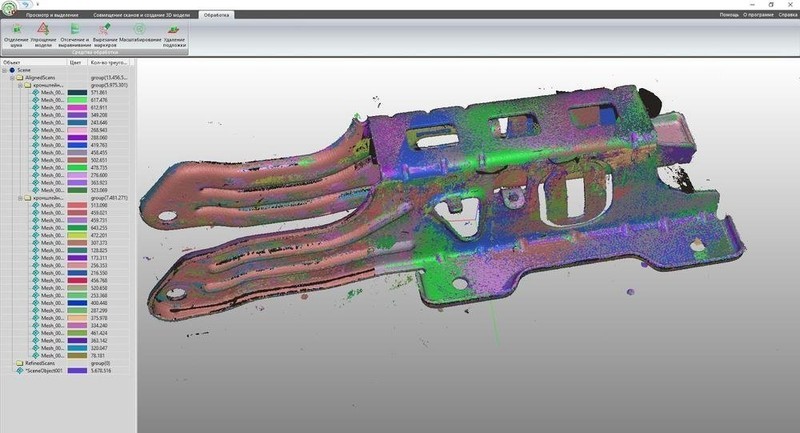

The RangeVision ScanCenter is a professional software suite designed for 3D scanning and subsequent post-processing of a render. It is a regularly updated and unified software suite that preserves all of its functionality no matter which device you use. Besides, it comes with a lifetime license key. The ScanCenter employs remarkably efficient scanning and post-processing algorithms that ensure high-quality renders alongside fast operation, and on top of this, it lets you work with large data volumes. Moreover, the software allows for one-click scans export and is compatible with every modern file extension.

The software installation and scanner calibration can be completed in a matter of mere minutes even if you are completely new to 3D scanning. There is a user-friendly setup wizard that will give you a helping hand and guide you through the wonders of calibration and installation procedures. The software can operate in three different scanning modes: an automatic turntable, marker, and a free scanning mode.

The ScanCenter is a perfect choice in case the user intends to employ the scans for color 3D printing, in computer graphics, animation, presentations, or other related applications, since it preserves both color and texture of the original object and features an advanced automatic white balance adjustment function. Additionally, there is an option to begin scanning with double exposure, which is particularly useful when working with contrasting objects.

By using the software and changing camera resolution, users can choose between faster scan speed and higher accuracy. Such an option is extremely useful in the case of scanning large objects with smooth surfaces (e.g. a car body). Besides, the software offers integrated photogrammetry support to minimize volume errors and quickly scan objects located far from each other without digitizing the area between them.

To streamline the workflow even more, there is a plethora of quality of life feature such as:

automatic visualization simplification (uses less RAM);

manual (three-point) and automatic (markers/geometry) alignment modes;

scaling and hole filling;

automatic and manual data post-processing, including automatic background removal.

Source: rangevision.com

Let’s quickly compare the RangeVision PRO Base and the Shining 3D EinScan-SP features.

|

Model |

RangeVision PRO Base |

|||||

|

Dimensions, mm |

408х350х125 |

570х210х210 |

||||

|

Manufacturer country |

Russia |

China |

||||

|

Scan volume, mm |

from 66х50х50 to 460х345х345 |

from 30x30x30 to 1200х1200х1200 |

||||

|

Camera resolution |

2 MP |

1.3 MP |

||||

|

Working range, mm |

350-900 |

290-480 |

||||

|

Accuracy, microns |

18-60 |

50 |

||||

|

Full color scans |

Yes |

Yes |

||||

|

Automatic turntable mode |

Yes |

Yes |

||||

|

Price |

on request |

$2,599.00 |

||||

As you can see, specification-vise, the RangeVision PRO Base is a cut above its Chinese counterpart. The thing is that the RangeVision PRO Base is a top-level device designed to be used in industrial and professional applications that require maximum precision and accuracy.

Source: rangevision.com

With the help of RangeVision 3D scanners, scientists of the Institute of Archaeology and Ethnography of the SB RAS create precise three-dimensional digital replicas of ancient artifacts for further research.

The collection consists of hundreds of unique and accurate archaeological renders, each of which can be 3D printed or e-mailed to a colleague for joint research.

Source: rangevision.com

“During scanning, the projector casts a moving grid of light and shadow patterns on the object, and the scanner, having received information about the grid distortions on the object's surface, creates a digital three-dimensional representation of the object. By rotating the camera and scanning the object from different angles, we were able to reach a 0.04mm accuracy, which is unbelievable.”- Pavel Chistyakov, a scientist of the Laboratory of Digital Archaeology explains.

Source: rangevision.com

Source: rangevision.com

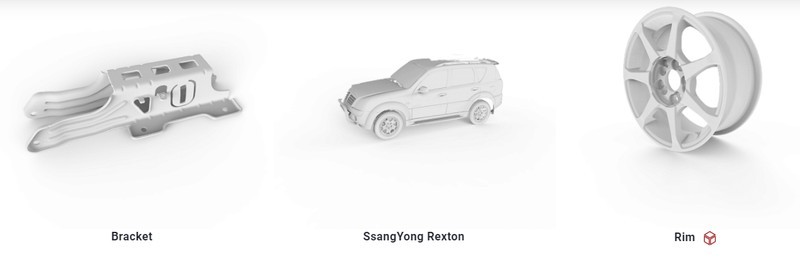

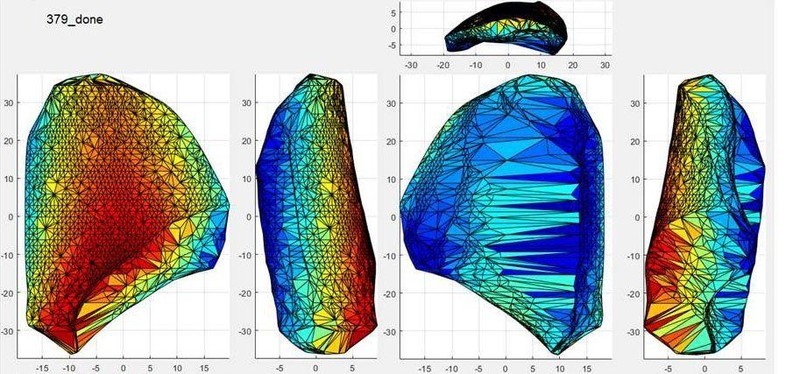

Located in Nizhny Novgorod, Krasnoye Sormovo is one of the oldest Russian shipbuilding companies that was founded in 1849. After a thorough analysis of the quality control workflow, the higher-ups concluded that using 3D scanning would be a better option for the quality control of unique cast parts. Before upgrading to 3D scanning technologies, they had to create complex, highly-specialized tools from scratch each time a new ship part came out to control its quality.

To start things out, the engineers used the RangeVision Pro to scan a controllable-pitch propeller hub with an outside diameter of 800mm and a height of 700mm. As a result, the actual dimensions of casting were verified to control the size of the allowances for the landing diameters. The engineers obtained all the information about the actual and desired geometry by the end of the day.

Source: rangevision.com

Source: rangevision.com

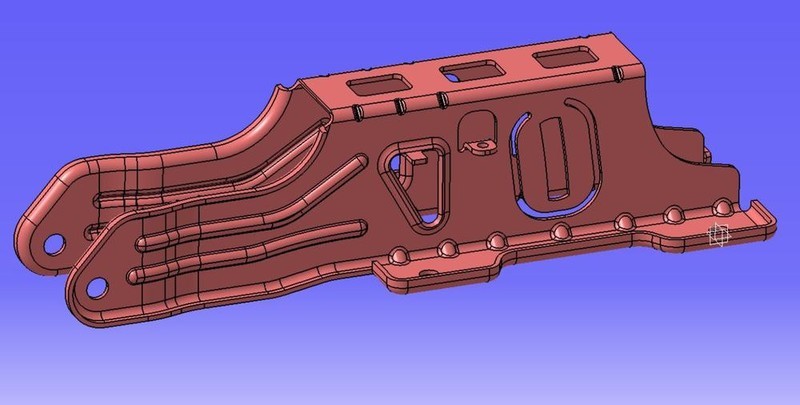

One of the RangeVision customers contacted the company with a request to create a 3D model of a 300 x 100 x 90 mm metal bracket and build its mathematical model. It took six hours to scan and verify the detail’s geometry, while post-processing procedures and the creation of a 3D model were completed in ten.

Source: rangevision.com

The challenging nature of this task was dictated by the fact that the bracket has been deformed prior to the scanning session, so the team had to restore its original shape. After a thorough warpage analysis, the RangeVision engineer has been able to create a final parametric model with millimeter-precision.

Source: rangevision.com

Source: rangevision.com

RangeVision is an experienced and trusted developer of innovative and professional 3D scanning equipment. At the time of writing the article, the company has a dealers network that counts more than 50 resellers worldwide. Besides, their annual sales grow in a fast and stable fashion, meaning that their products become more and more demandable with each passing year. The RangeVision Pro 3D scanners are mainly applied in architecture, product design, industrial manufacturing, education, art and design, and automotive industries.

You can purchase the RangeVision high-precision 3D scanners from Top 3D Shop. These professional multi-purpose devices come with the manufacturer’s warranty and a dedicated software with a lifetime license. Besides, our team will make sure to provide you with the best service possible, just like we always do.

Update your browser to view this website correctly. Update my browser now

Write a comment