Ultimaker is a famous brand that has been around since 3D printing was only becoming a mass phenomenon. Over the past 10 years, the group of enthusiasts evolved into a global company with headquarters in the Netherlands, offices in the US, and distributors all over the world.

In this review, we will tell you about one of the manufacturer’s top-notch products — the Ultimaker S5 3D printer. Read on to learn about all the key features of the device.

The first 3D printers by Ultimaker were made of plywood, with many fastening components printed on the same handmade devices. Nevertheless, the design turned out reliable, and proper improvements resulted in the product becoming a recognizable brand. Such printers were called Ultimaker Original; they were sold in the official store in the form of kits until recently.

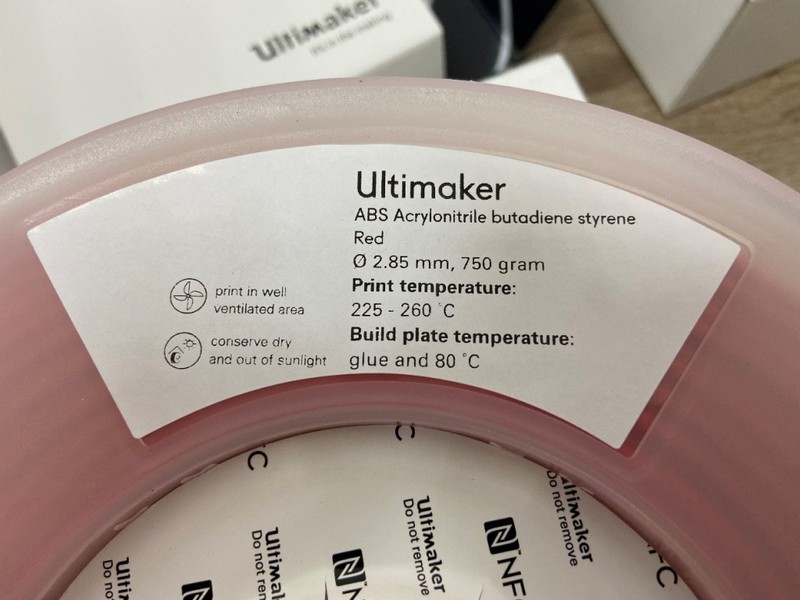

The main distinguishing feature of Ultimaker 3D printers is the general "architecture" of the models, which is modified and refined with each new product. All Ultimaker devices have a lightweight but durable composite body and print head, into which plastic is fed by a mechanism from the back wall (Bowden type) with a filament diameter of 2.85 mm.

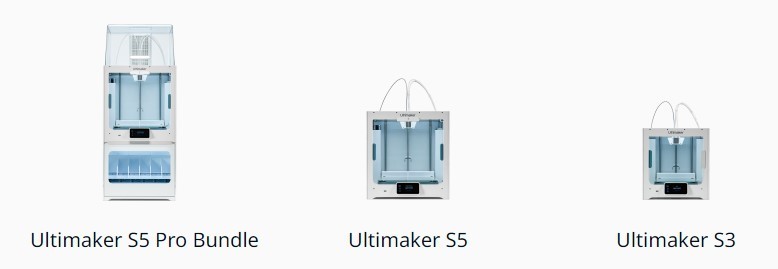

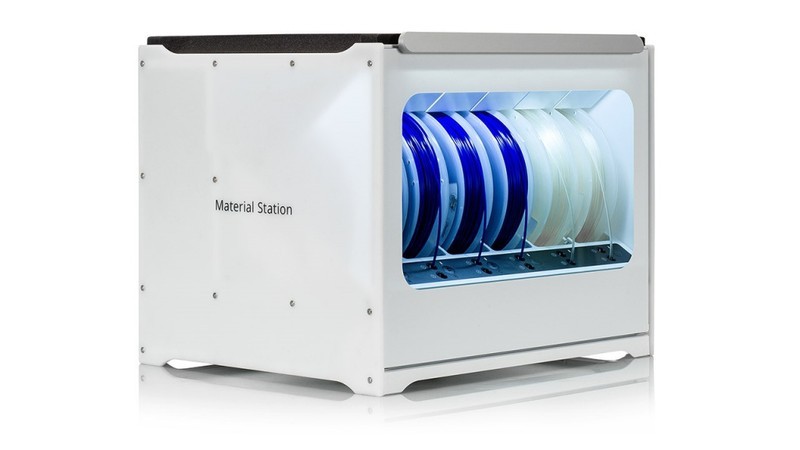

The Series S includes several products, the most prominent of which is the Ultimaker S5, its younger version Ultimaker S3, and an advanced option with automatic material handling and environment control — the Ultimaker S5 Pro Bundle.

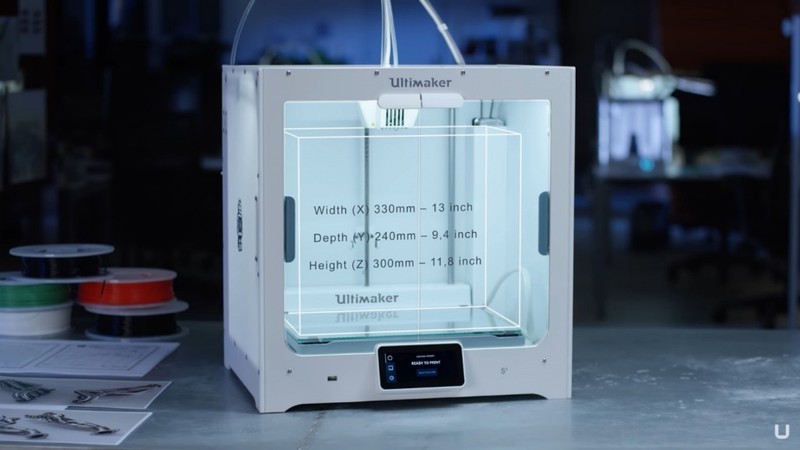

The Series S is the 4th lineup of the company's devices. It features the characteristic recognizable design of the body made of white translucent polymer and a scissor kinematic scheme. In addition, the Ultimaker S5 boasts a cloud ecosystem, the updated proprietary Cura slicer, a new system of quick-replaceable modules of the Print Core extruder, and many other innovations.

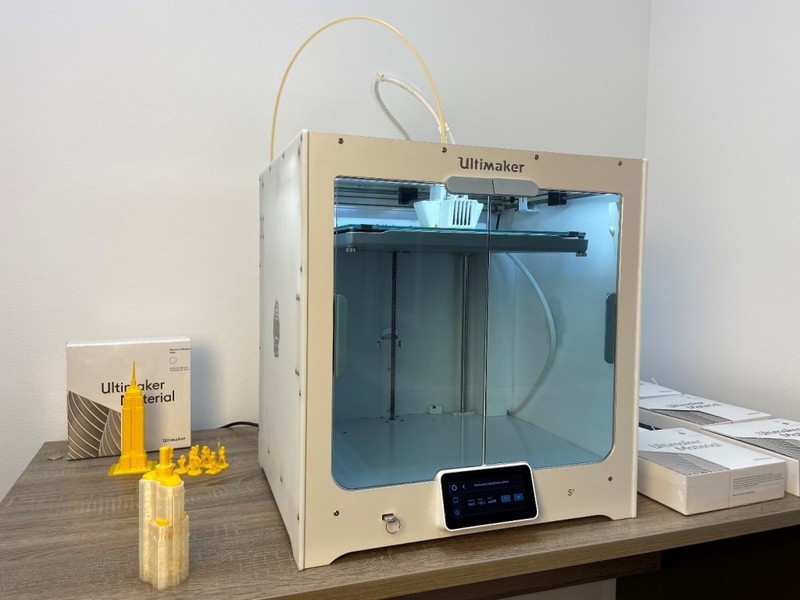

The specifications of the Ultimaker S5 meet the standards of premium printers. An advantage of this model is the simplicity and conciseness of the structure, making for the balance between functionality and minimalism. While rather lightweight due to the composite body, the machine has a fairly large build volume. In this case, the body is load-bearing, and the entire kinematics is attached directly to its walls, the weight having a positive effect on the print speed.

The device features auto bed leveling, replaceable adhesive plates (glass or aluminum), as well as a built-in camera to monitor the process, representing a modern solution with enviable quality and thoughtful design.

The printer is packed in a cardboard box with polyethylene foam inside. The supply package contains:

On the front of the device, there are large inspection doors with strong hinges and aluminum handles with magnets for a better fit to the frame. The hinges are made of non-polished cast aluminum, clearly designed specifically for this model.

At the bottom are a USB connector for a flash drive and a touchscreen. At the front, the frame is made of a composite sandwich panel several mm thick, with a glossy white finish. The same material is used for the bottom and base.

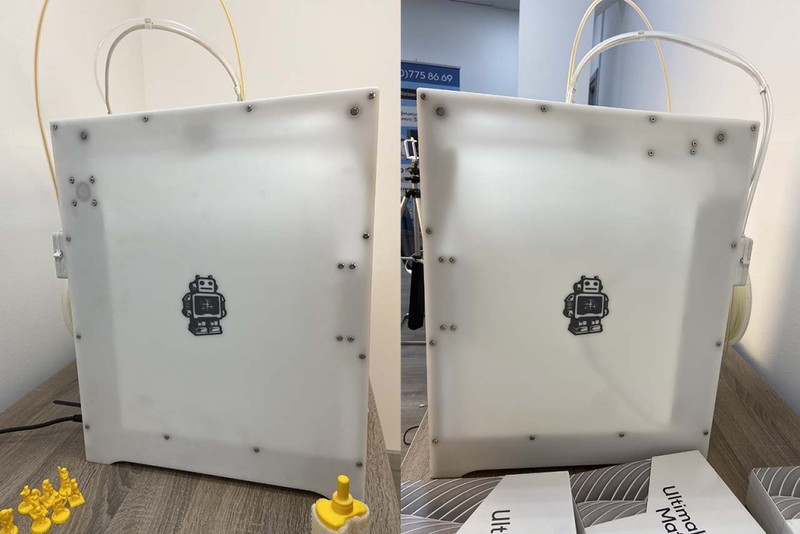

On the sides are the company logos — a stylized futuristic robot. The material of the walls differs from the general body and is made of cast translucent plastic with milled grooves for kinematics.

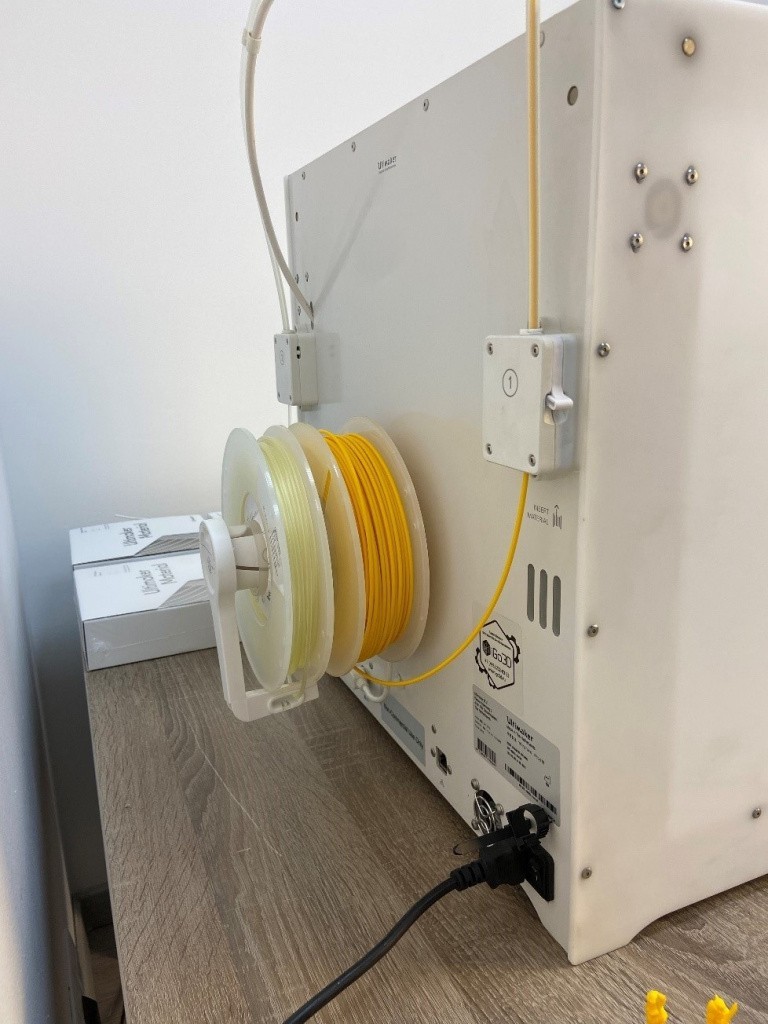

At the back, we can find a spool bracket mount, material feeding mechanisms, power connector, and ventilation holes.

There is also an Ethernet connector, a plug for the NFC spool holder, and a connector for a material station.

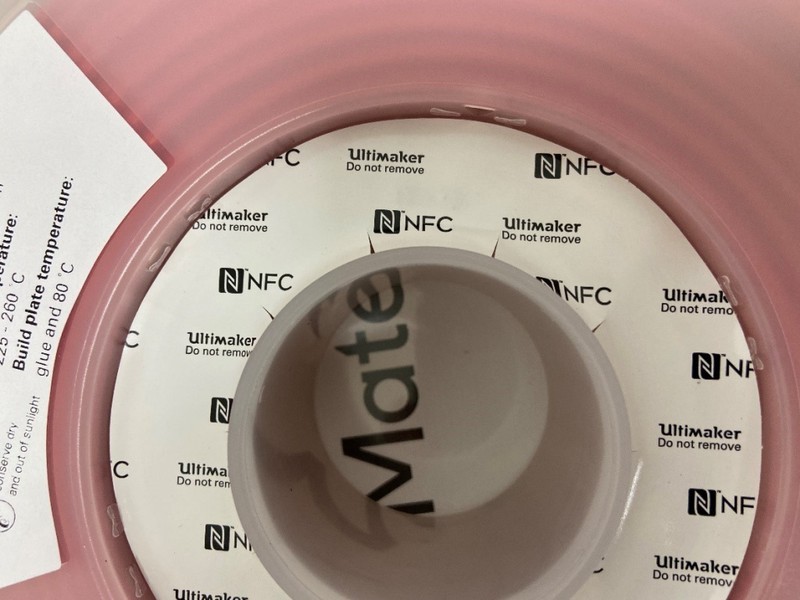

Please note that after removing the printer from the box, the spool holder should be installed on the wall and connected to the appropriate plug, otherwise the system will not be able to fully operate. When the printer is connected to Cura, the smart slicer will automatically detect the material settings.

The main difference between the Ultimaker S5 and the previous devices by the manufacturer is the full support of printing with two materials, which was postponed for quite a long time because of the need to refine the system.

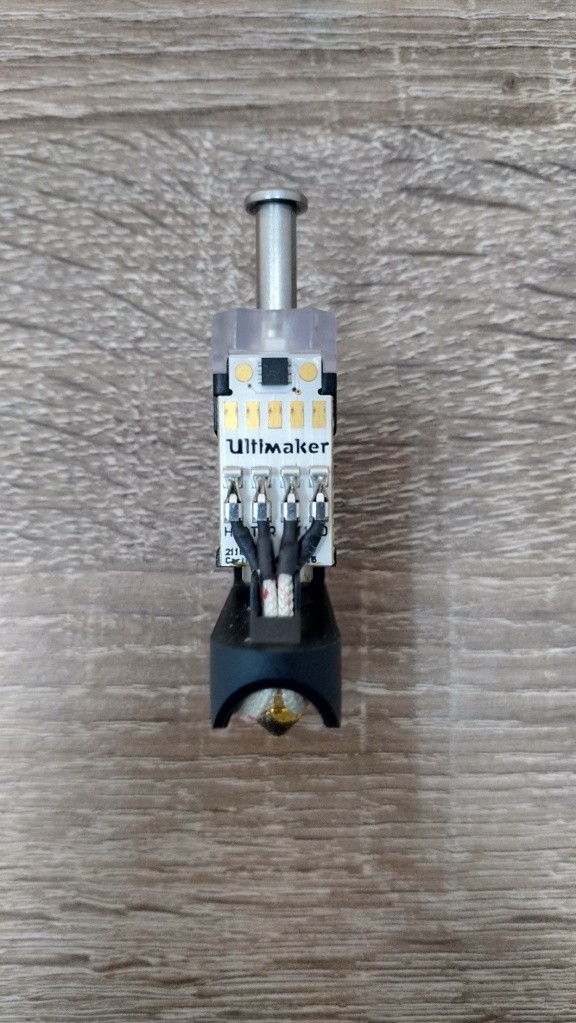

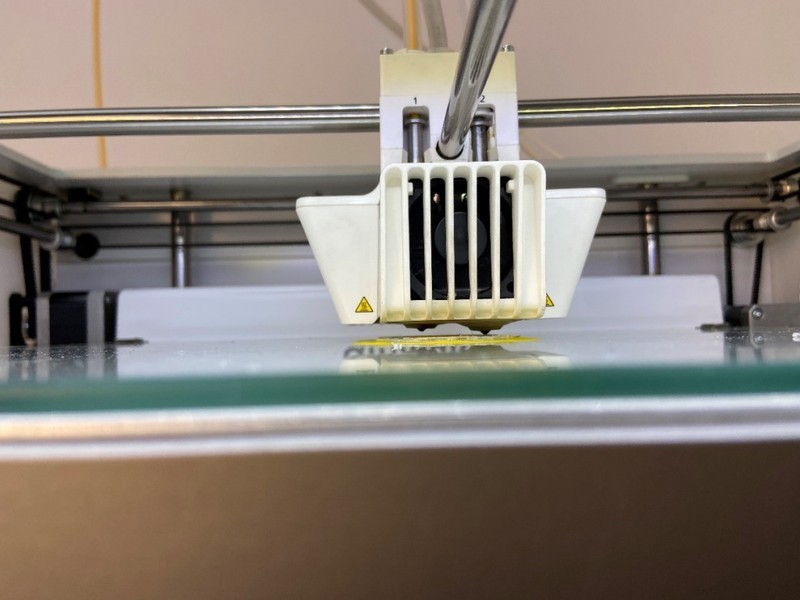

The new model introduced a completely reimagined printing unit system. Instead of the outdated Olson Block, there came a system based on quickly swappable Print Cores, which are a monoblock cartridge containing a cold end, a hot end, and a nozzle. It is important to note that some materials (for example, PVA) also require a separate block cartridge: the requirements for the roughness of the extruder tube and the peak heating of the cold zone for ABS and PVA printing are very different. This problem was solved with the help of the quick-change cores.

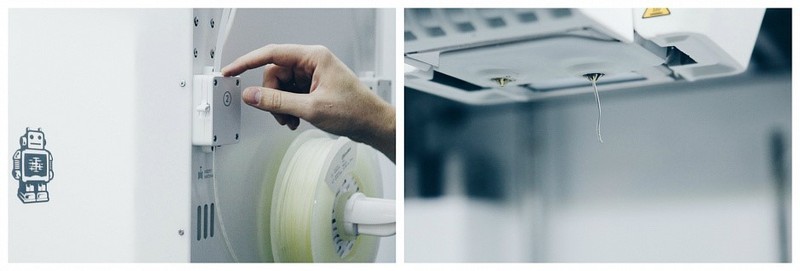

To install a core in its place, it is enough to remove the front cover of the printing unit, press the button on the cartridge, and pull the core down.

To print with soluble supports, replace the right extruder with a PrintCore BB for PVA printing.

Change back to the PrintCore AA for high-temp or PLA printing.

In addition, Ultimaker offers specialized extruder cartridges for printing highly abrasive materials such as carbon fiber. For this, there is a special PrintCore with a diamond nozzle tip.

Сartridges of different performance are available with four nozzle diameters — 0.25 to 0.8 mm.

In addition to the cartridge system itself, Ultimaker has also expanded its range of branded filaments. The following two soluble materials are designed for different purposes.

The Infinite Aquasys 120 dissolves in water 6 times faster than PVA and withstands chamber temperatures up to 120 degrees.

The Ultimaker PVA is a classic PVA filament for creating models with complex geometries.

Apart from that, there appeared new durable and heat-resistant materials.

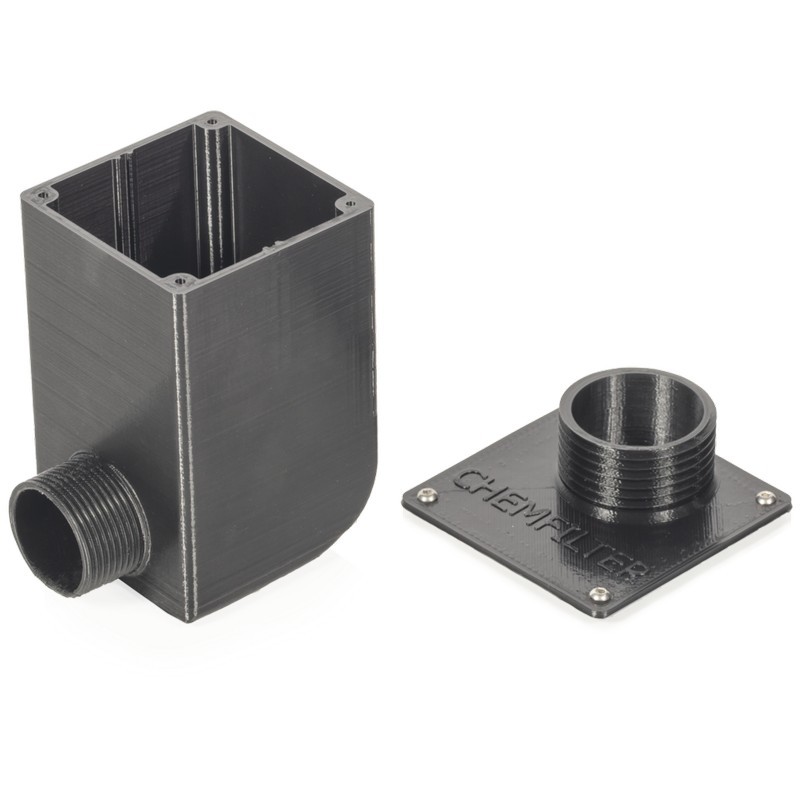

Based on PA6/66 polyamide, the Ultimaker Nylon is resistant to chemicals and aggressive environments, featuring reduced shrinkage and increased strength.

The Ultimaker CPE + is designed for use in prototypes and commercial products that come in contact with oil, gasoline, and other corrosive fluids.

The Series S is also compatible with third-party filaments, but the print quality may not be at such a high level. In this case, you will also need to make some adjustments in Cura.

The printer also received a modified material feeding system. Now the blocks are equipped with filament sensors, which, along with the NFC technology, enables the machine to accurately control the feed of material and pause printing if the filament runs out or errors occur.

In this case, the device can also continue printing with another spool. It is noteworthy that this feature is available only in the Bundle Pro version equipped with a system of uninterrupted material feed.

If one of the spools suddenly causes a problem, the smart system will automatically change the material and continue printing. All this became possible thanks to the change in the digital platform of the device.

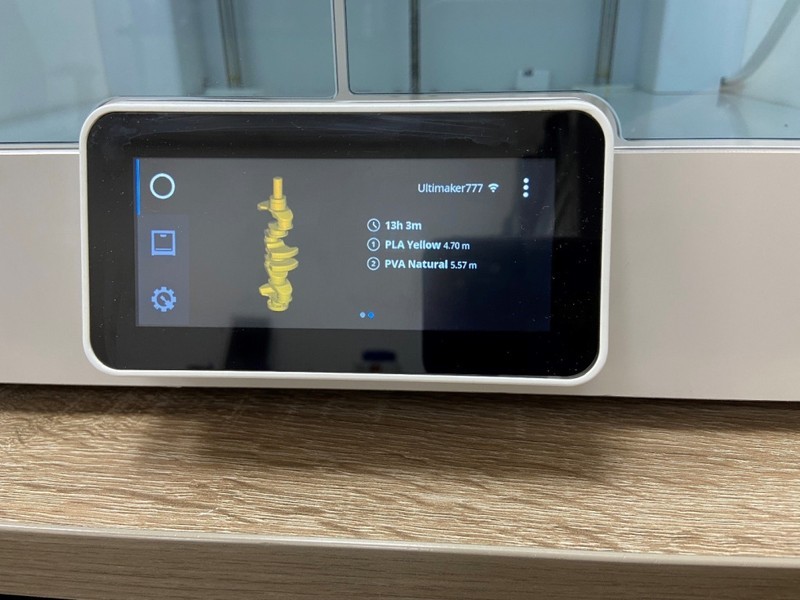

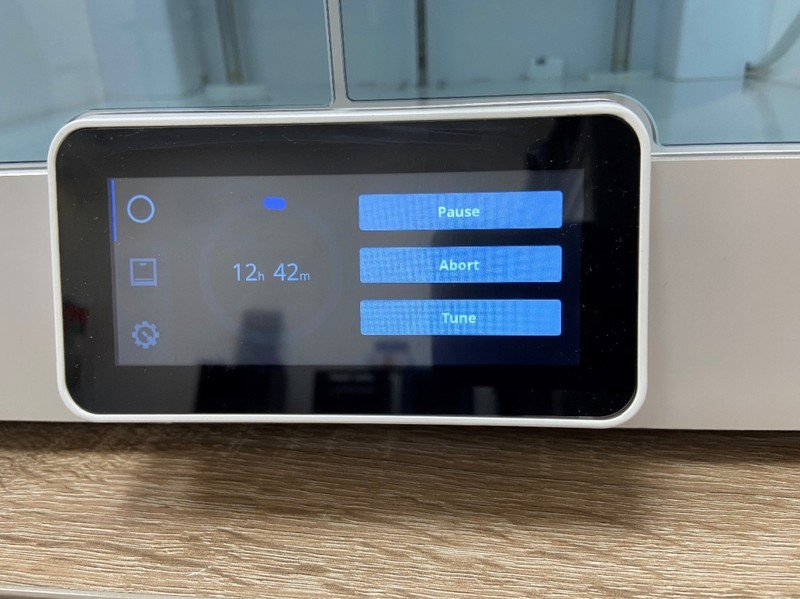

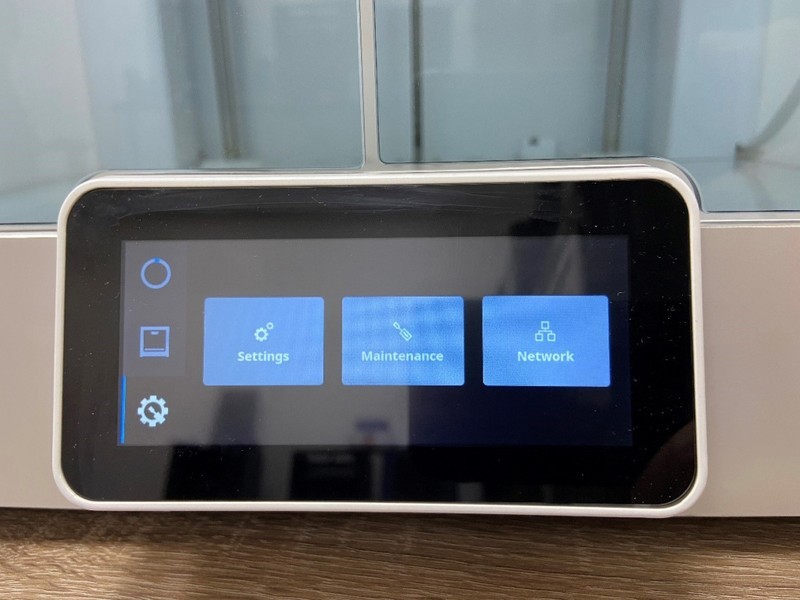

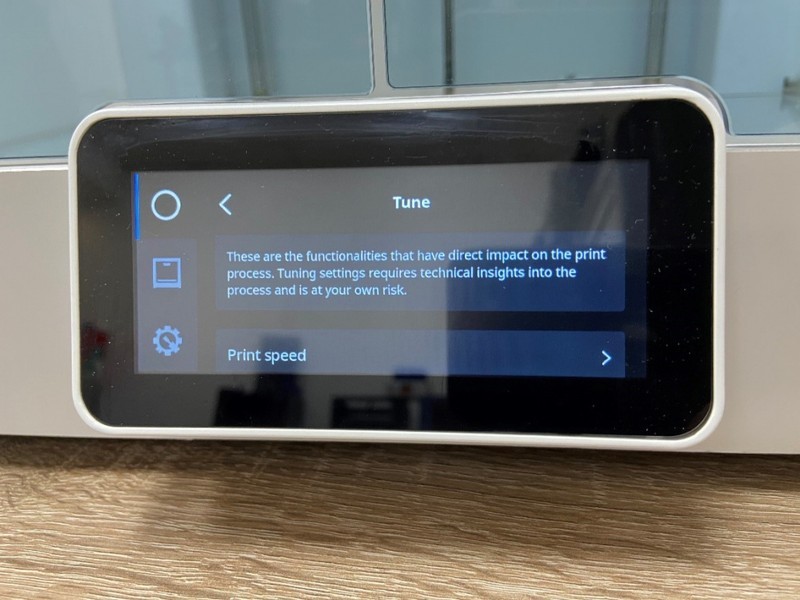

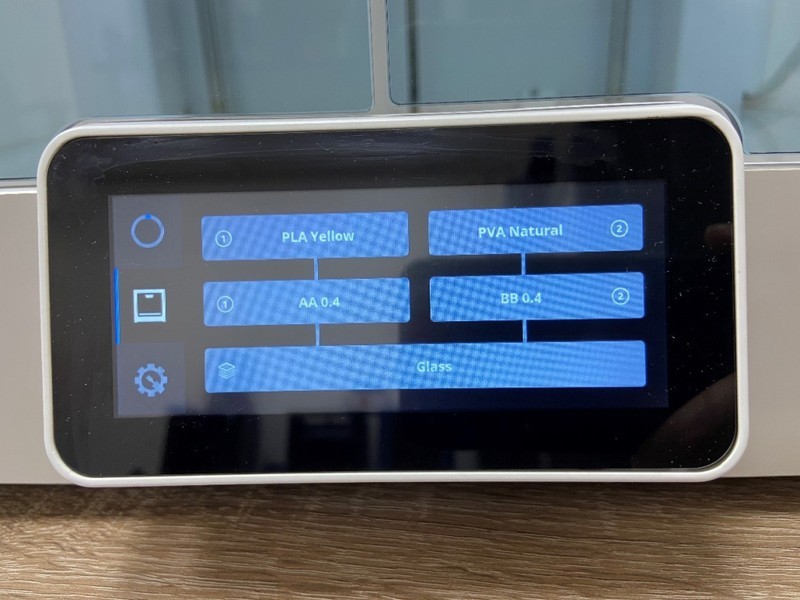

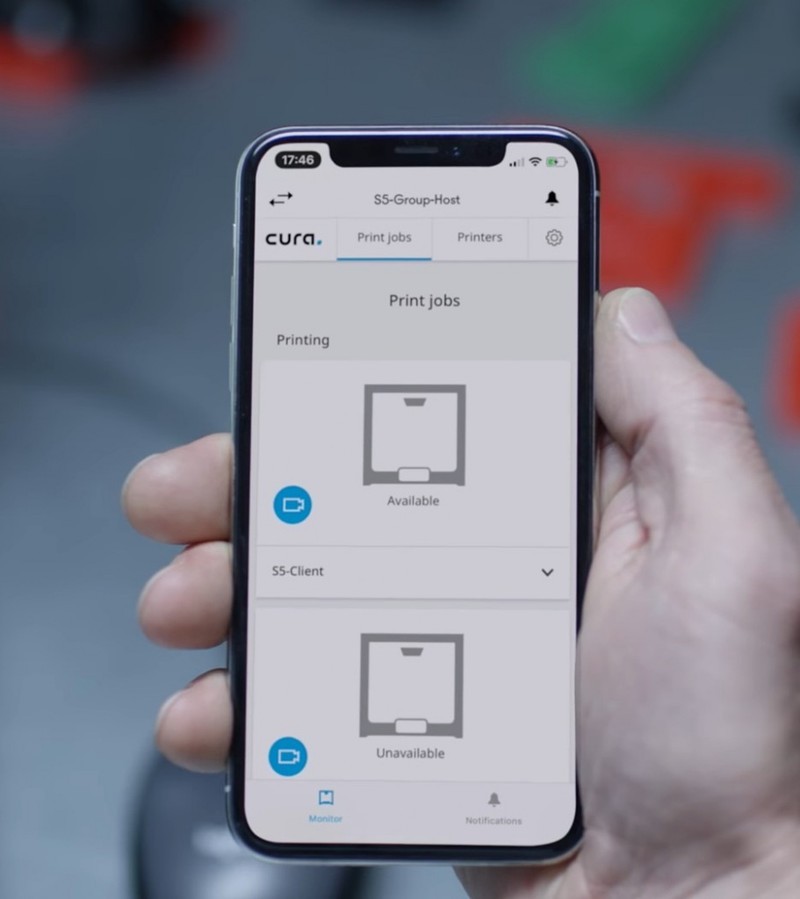

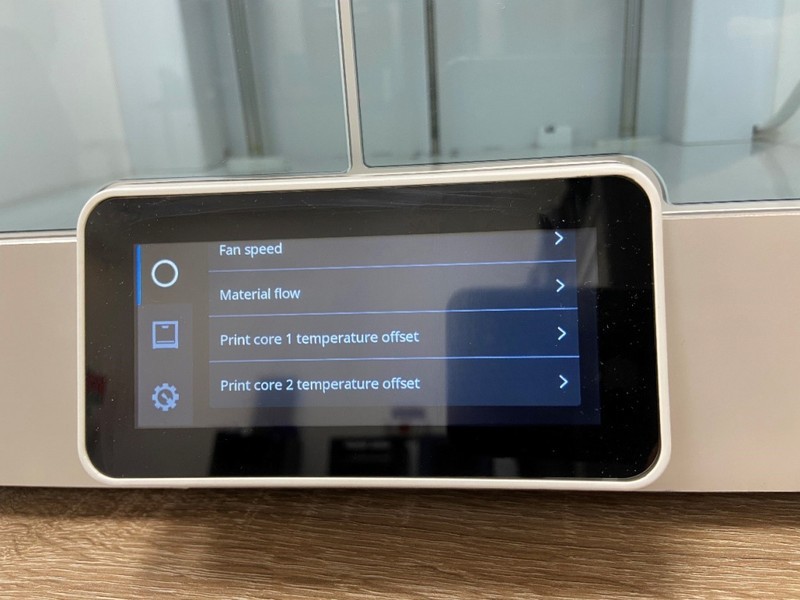

The printer has a 4.7-inch full-color touchscreen and a cloud-based smartphone application that connects to the printer via Wi-Fi. The display of the device was completely redesigned while retaining all the functionality of its predecessor.

It offers all the necessary settings for the printer, including the ability to change the parameters of print speed, temperature, and more.

Also available are quick filament changes and detailed tips, just like in the new Raise E2.

It also allows you to specify which Print Cores are installed on the printer at the moment, as well as which print surface you are going to use.

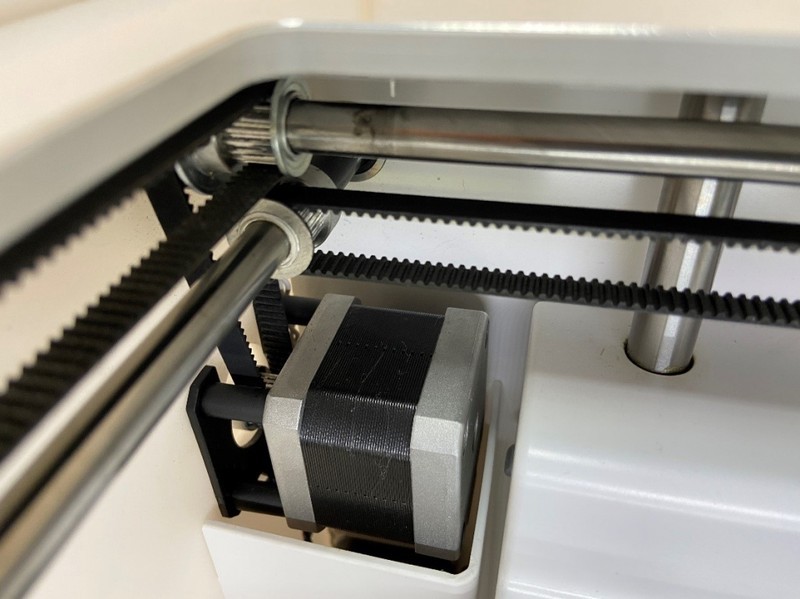

From the technical point of view, the kinematics of the printer has not changed much. It still uses a scissor kinematic pattern with a Bowden extruder. The XY axes adopt 6.5 mm drive belts, a GT2 analog, and Nema 17 stepper motors. On the other hand, the axle pulleys and bearings are slightly larger compared to previous models.

The main changes occurred in switching the active nozzle — it is done automatically using a special hook on one of the axes.

The print unit drives up to this hook, changes the active nozzle, and continues printing. This solution makes the unit exceptionally light because it does not require additional motors, which has a positive effect on the print speed and prevents parasitic oscillation.

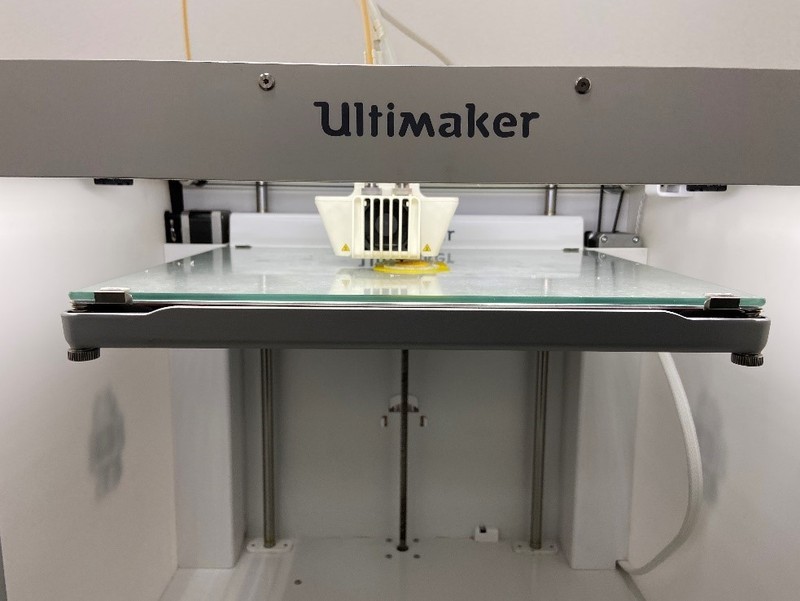

The Z-axis uses a free-end trapezoidal screw that drives a light but strong die-cast aluminum print bed with internal stiffeners.

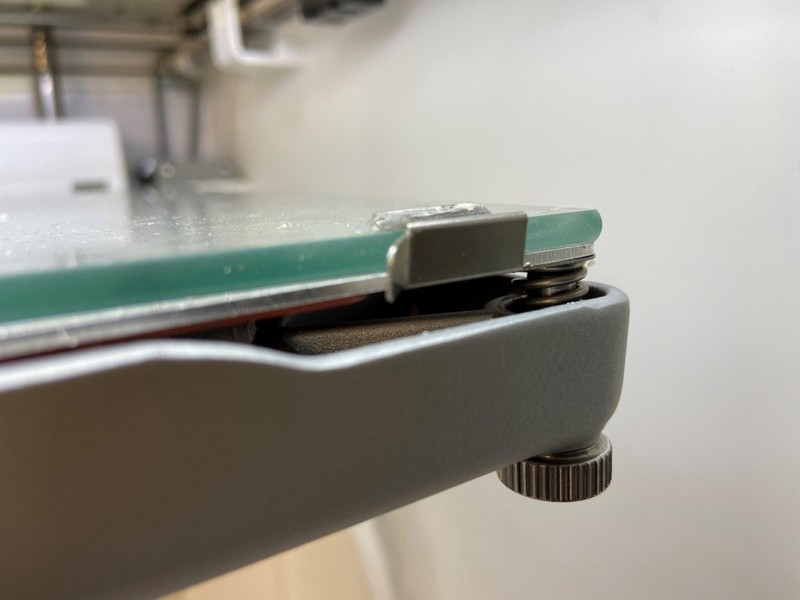

The bed is leveled automatically, but the three calibration screws and clamps are still there.

Oddly enough, the manufacturer uses mechanical end sensors on all the axes in this flagship device — probably for reasons of reliability.

The build volume of the printer is 330 x 240 x 300 mm, which is enough for most tasks. Due to the lightness of the design, sagging and deformation do not occur.

The print unit contains an active cooling system and is built on the basis of swappable extruders that we discussed earlier. The filament is fed from the spools on the back wall with the smart NFC system telling the machine what kind of plastic is being used.

Thus, if the material has run out, the replacement of spools takes place in a matter of seconds. The printing setup in the slicer is done quickly as well.

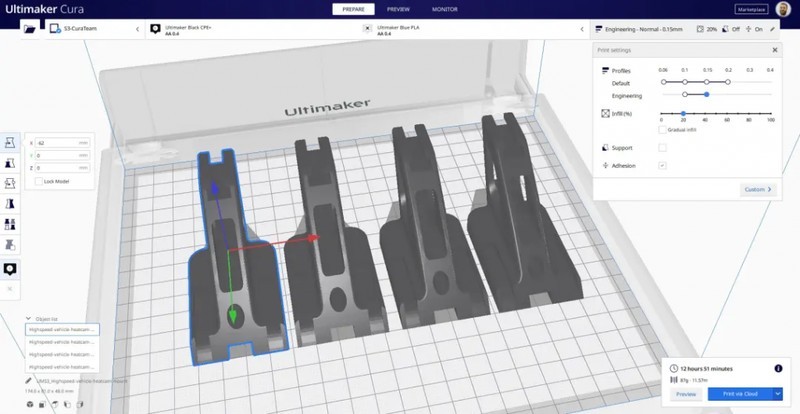

The Ultimaker S5, like all other devices of the company, is designed to run on the proprietary Cura software. Version 4.6.2 is a powerful versatile slicer that supports not only Ultimaker products but also a huge number of devices around the world.

The connectivity includes both a wired connection and cloud service through a special app on a smartphone.

Select a 3D model, connect the device, configure the required settings, and start printing — "over the air" or with the help of a USB stick.

The whole process of starting a print job takes 5–7 minutes. The printer heats up instantly, and the NFC system does not require configuring the material.

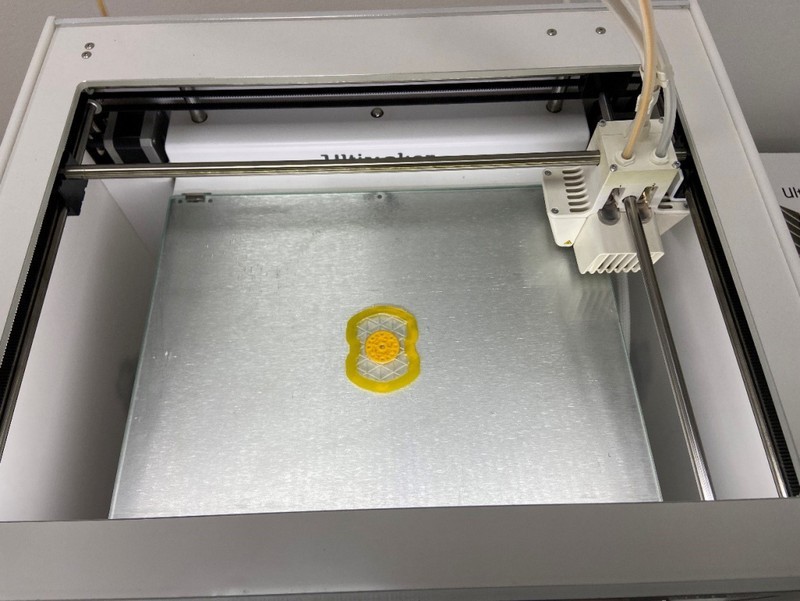

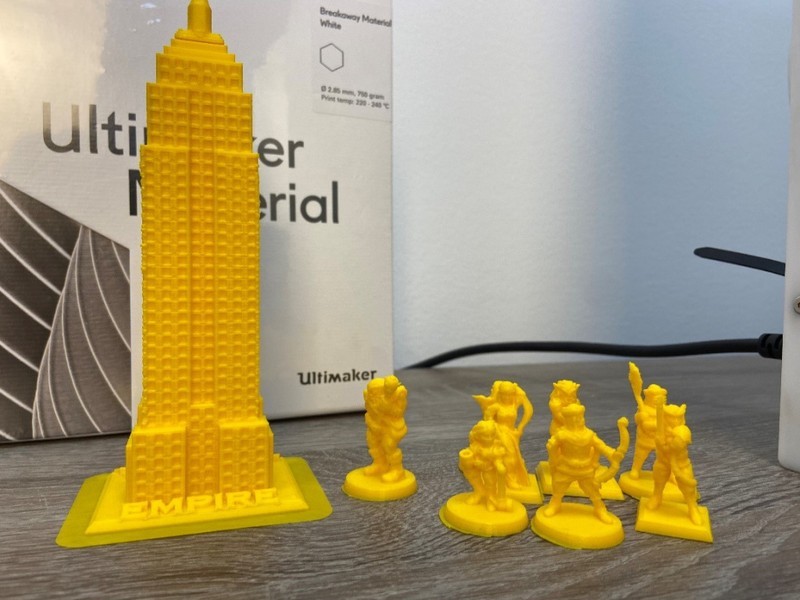

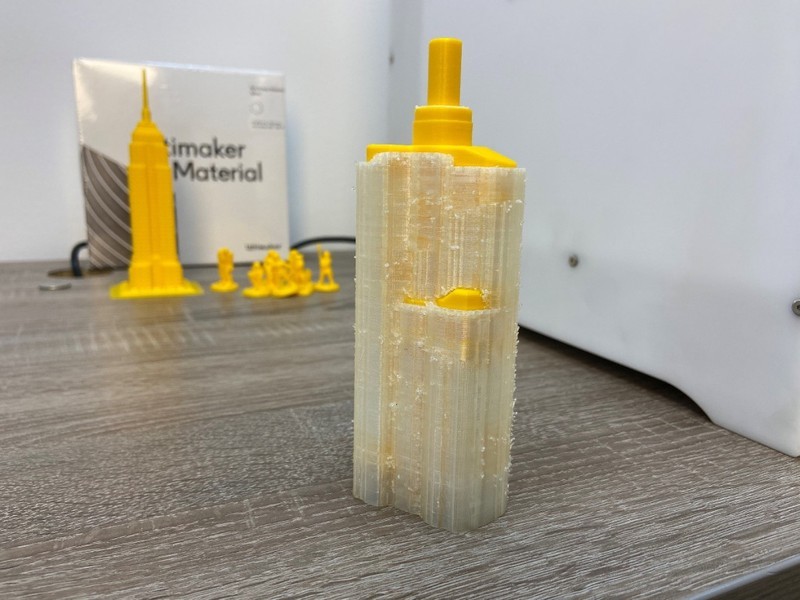

We used native PLA as the main material and native PVA for supports. Layer height: miniatures — 0.1 mm, crankshaft and tower — 0.2 mm.

In more than 40 hours of test prints, the device showed excellent stability. At 100 mm/sec, the geometry turns out great, which is clearly seen on the building model in the photos.

The Ultimaker S5 3D printer seems to have set a new benchmark for “plug and print” devices. Each element of the machine is created with the end-user in mind. The well-developed display interface, slicer functionality, kinematics, a brand new line of filaments, and numerous smart features ensure positive experience and quality results. The printer will find its applications in professional design and engineering, as well as in other areas where its advantages can be best utilized.

Update your browser to view this website correctly. Update my browser now

Write a comment