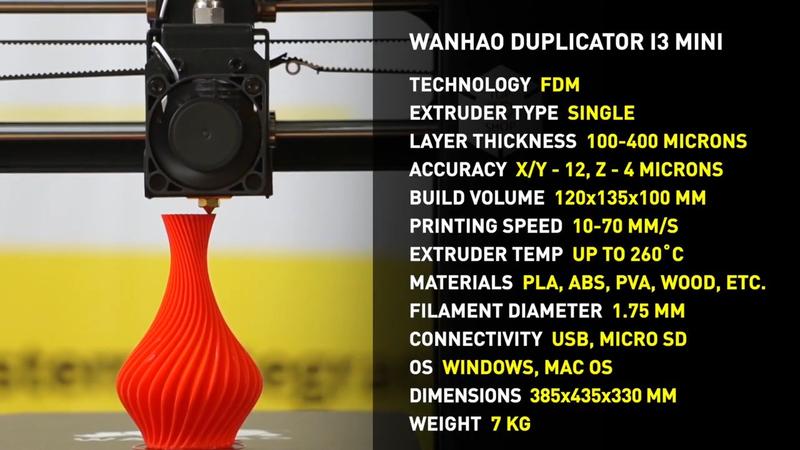

Hi everyone! In this review we will talk about the Wanhao Duplicator i3 mini 3D printer, the smallest model in the line of Wanhao FDM devices. Learn more by watching the video and reading the article.

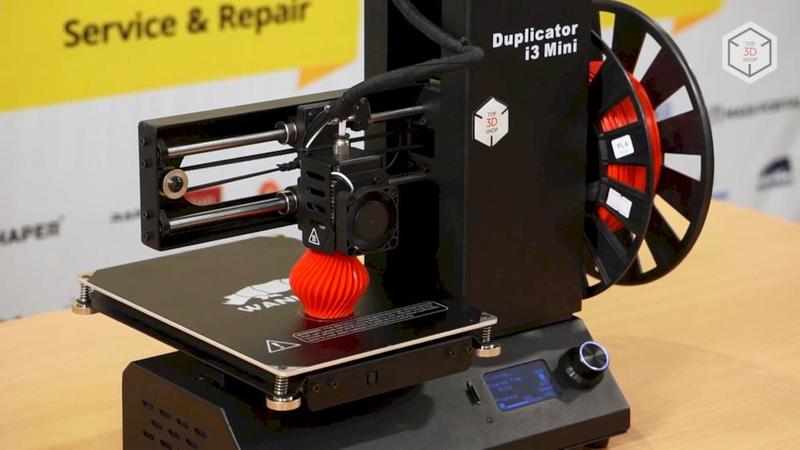

As has been noted above, i3 mini is the smallest model in the Wanhao Duplicator lineup. The 3D printer can be placed on two A4 sheets. As a result, it has a small build volume compared to other Wanhao Duplicator models. The miniature 3D printer does not look like other models of this series, whose design was borrowed from the legendary Prusa i3.

The working volume is 120x135x100 mm, which allows you to install it in the most cramped and cluttered places. The minimum layer thickness — 100 microns — is close to the corresponding characteristics of older models, i3 and i3 Plus.

The maximum print speed for the MK10 extruder used in the Wanhao Duplicator i3 mini is 70 millimeters per second. Not the highest indicator, but taking into account other key features, it can be considered acceptable. The extruder temperature can reach a mark of 240 °C for long printing and 260 °C for printing for a short period of time. A fan is installed on the extruder for cooling.

The coil with plastic is placed on the right side of the bracket. The printer uses filament with a standard diameter of 1.75 mm, which is fed into the extruder through a Bowden tube.

A Wanhao signature cover is pasted on the bed. There is no platform heating, so it is recommended to use PLA for printing. The manufacturer clearly indicates in the manual that the printer is only designed to work with PLA and nothing else. Another acceptable option is Wood, plastic with fine wood dust as a filler and PLA at the base.

The printer casing is made of 2-mm-thick sheet steel. The Z-axis is moved with the drive screw, the X and Y axes are belt driven. The extruder travels along the X-axis on two sturdy and well-lubricated linear bearings. The Y axis is responsible for the platform and has a structure identical to the X axis, which is quite normal for the extruder but not always enough for the bed.

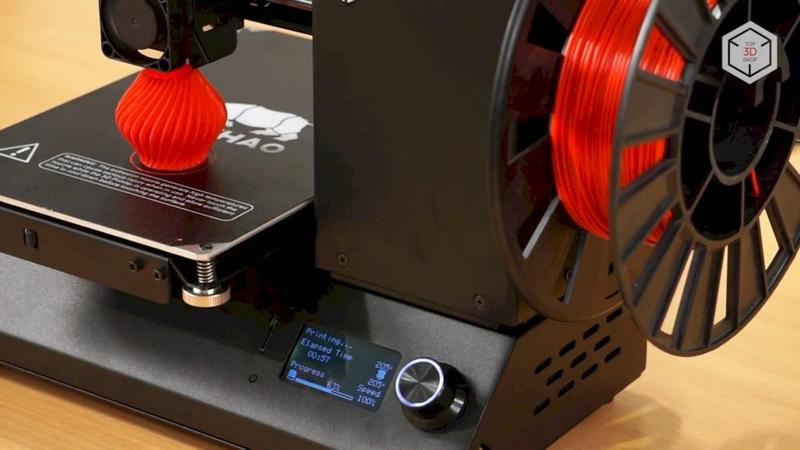

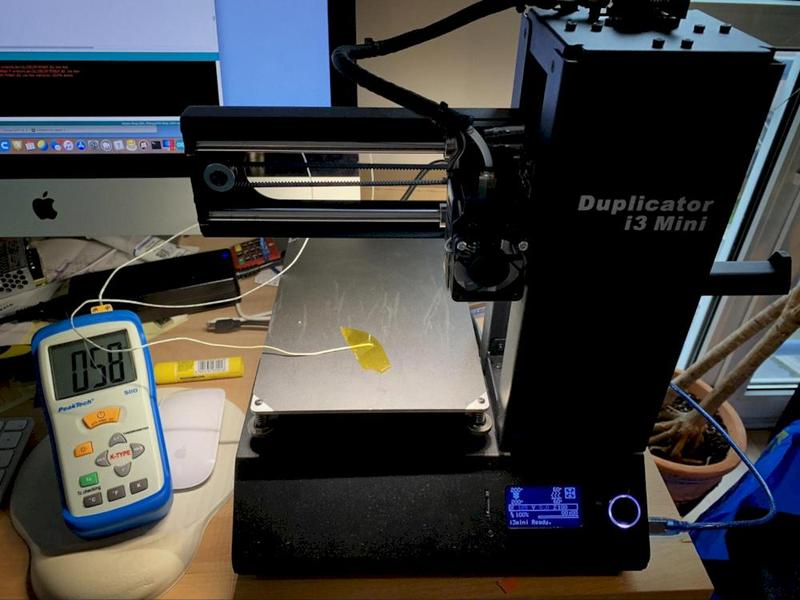

The memory card slot and all printer control elements — a monochrome LCD, universal knob and Reset micro-button — are located on the front panel of the printer, which is placed at a convenient angle for use.

The display shows basic information such as elapsed print time, completion percentage, nozzle temperature, and print speed. The only parameters that can be changed during print are nozzle temperature and speed.

Source: wanhao3dprinter.com

Electronics are located at the bottom of the printer which also serves as the horizontal part of the frame. The inside is very simple — a Wanhao board (presumably an analog of Mega 2560) and a power supply. A small fan is used for cooling.

i3 mini comes in a sturdy cardboard box, the items are securely packed.

The delivery includes:

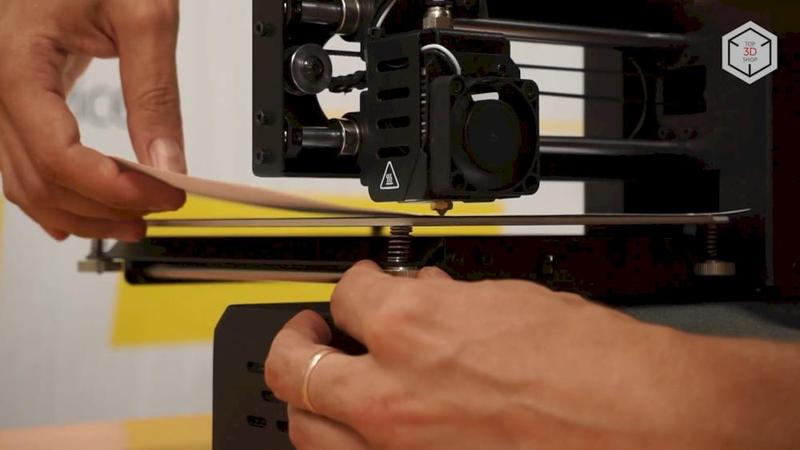

The printer comes fully assembled and allows you to print almost as soon as you get it from the box. All you have to do is just install the spool holder, calibrate and load the filament.

Calibration of the 3D printer is carried out according to the classical scheme — by adjusting the height of the bed using four screws under the platform.

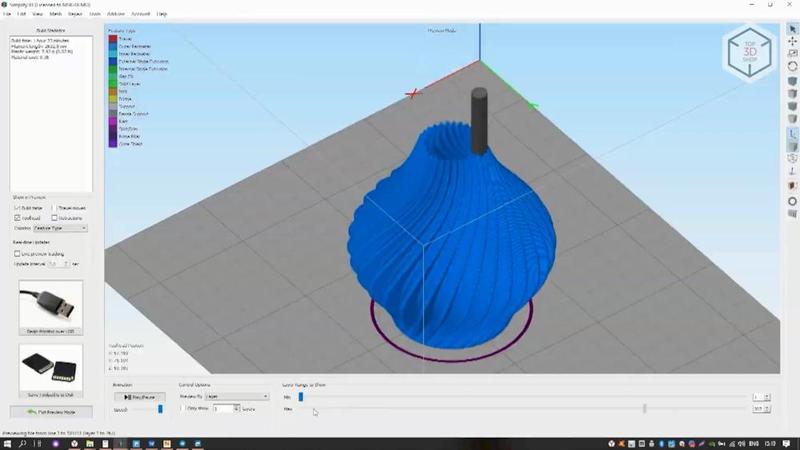

As a software for preparing digital models for printing, the developer traditionally offers to use the Cura Wanhao Edition slicer. It has a ready-made profile for printing, which is a huge advantage for beginners. Experienced users can employ any other available software for these purposes.

A finished file containing the G-code — a set of control commands for printing — is transferred to the printer memory using a TF memory card also known as micro-SD. The same procedure can be performed via the wired connection to a computer, with the USB port located on the right side of the printer.

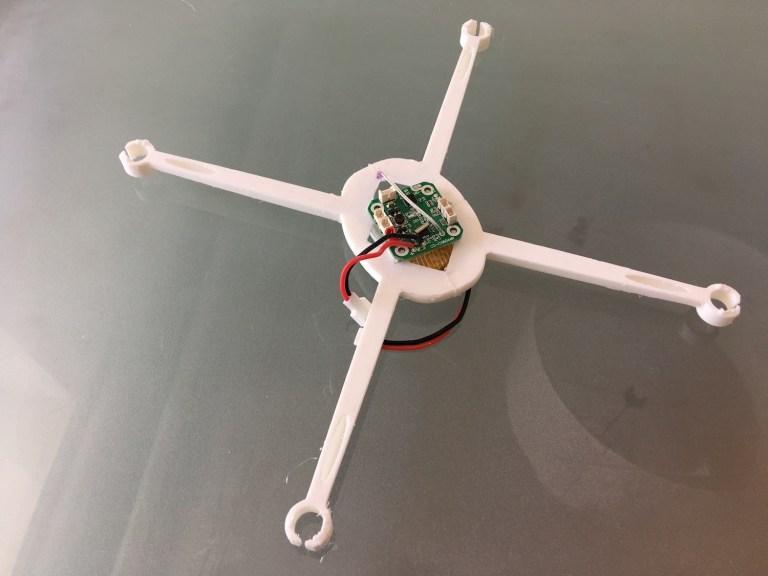

Quadcopter frame parts / Source: backyardrobotics.eu

Quadcopter frame arm after light sanding / Source: backyardrobotics.eu

Micro quad frame / Source: backyardrobotics.eu

Source: www.thingiverse.com

"I use my i3 Mini when I'm stuck in an office for a long time and can print small items here and there. So since I need my mini to always be portable, I began adding portability items to it, such as this cord wrap holder. have made them out of PLA, they work really good," tells cpoctc.

Source: www.thingiverse.com

Meteozond writes:

"I've found original mount not stable enough for my camera. This model got additional reinforcement. I printed black PLA with 80% filling. This mount significantly improves print video".

Source: drucktipps3d.de

"As I disassembled the printer, I saw on the motherboard a connector with the promising label Bed Add and another one labeled FAN. For replacing the bed, I needed: power supply 24V / 160W, 4-pin connector for attaching the panel of the power supply KPJX-PM-4S-S, MOSFET switching board, heated platform with thermistor (150mm x 150mm) 80W / 24V, 24V LED strip.

Source: drucktipps3d.de

"I shortened the LED strip, stuck it under the X axis and connected it to the FAN connector on the main board. In place of the old power supply, I put the MOSFET board, connecting to the network through a new, external power supply. I used the TH3D firmware. It requires only a few configuration settings, in pin assignment and thermistor selection.

Now, with a heating power of 80 watts, the bed is heated to a temperature of about 85 °C without additional insulation. This is probably not quite enough for ABS but still better than with no heating at all," tells robbeh.

Let's summarize the main pros and cons that we found out during the review:

Pros:

Ease of use — the printer is fully assembled and requires few steps for first printing;

Quality PLA printing — the manufacturer claims that the printer is only intended to work with PLA and nothing else;

Convenience of operating by means of the display and universal knob;

Massive hard casing eliminating all vibrations;

Low price.

Cons:

Small print area — 120x135x100mm;

There is no platform heating, which dramatically reduces the ability to print with any filament other than PLA;

Open housing.

Reliable, easy to use and inexpensive, Wanhao Duplicator i3 mini, despite some drawbacks, is a good choice for novice users. It will be perfect for educational institutions and domestic use. The model is closest to the consumer class in terms of simplicity and reliability.

Buy Wanhao Duplicator i3 Mini and consumables for it at Top 3D Shop — acquire an original device with an official warranty and the best service.

Update your browser to view this website correctly. Update my browser now

Write a comment