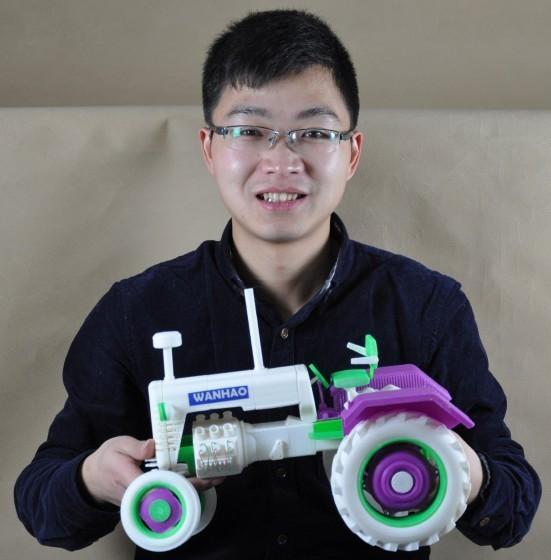

Now that 3D printers are no longer mere strange and expensive toys, they emerge as full-fledged working tools in workshops of designers, engineers, and other professionals. Consumer attitude towards Chinese products is also changing, gradually becoming associated with high technologies and innovations. A huge role in that is played by the “young tigers” of the Chinese economy — such as Wanhao, which in just a few years has grown from a small company of students into a large international manufacturer of 3D printers.

Learn more about the history of Wanhao and its products from this article.

Source: wanhao3dprinter.com

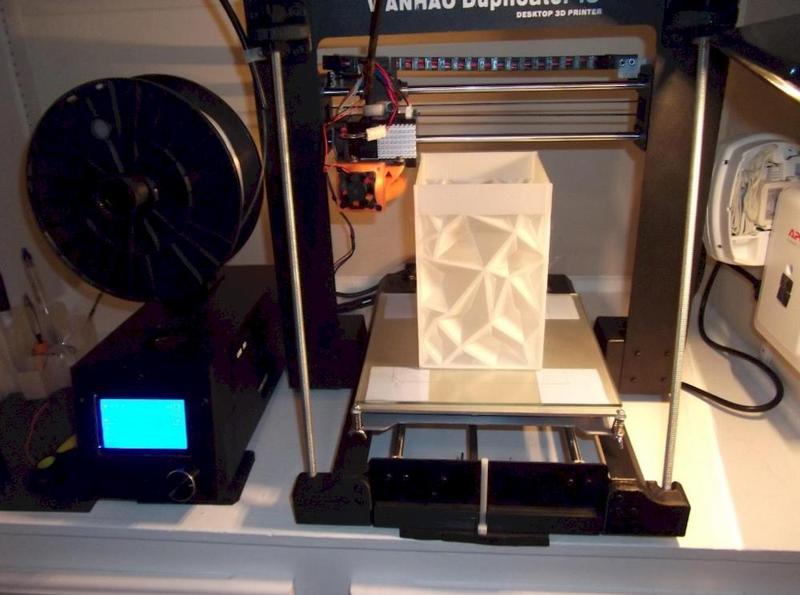

The history of Wanhao began in January 2011, when a few roommates in a college dormitory spent their last money on a Makerbot Thing-O-Matic 3D printer. Having studied and drastically redesigned the construction, by October 1 of the same year the students were able to realize their dream and create their own 3D printer, calling it Duplicator One. This machine combined the successful design elements of RepRap and Makerbot 3D printers, a new extruder, and a number of Wanhao's own improvements.

Although the first generation of Wanhao devices required the direct connection to a computer, the model turned out to be popular with customers due to its low cost, reliability and simplicity, which allowed Wanhao to get funds for developing a new generation of 3D printers called the Duplicator Two. The new series already had its own controller, LCD display and control panel, and could also work autonomously, using objects from an SD card for printing.

In August 2012, WANHAO was listed on Alibaba, which gave it access to the international market. According to experts' estimates, today the company employs about 500 people, and its annual turnover exceeds $25 million. WANHAO offers inexpensive and stable machines for 3D printing, changing the attitude of people to products with the tag “MADE IN CHINA”.

Source: wanhao3dprinter.com

Source: whmould.com

The Wanhao product line includes:

Source: all3dp.com

Instead of heating the plastic filament in an extruder to a liquid state, DLP/LCD printers use liquid photopolymer resins that harden under the influence of UV radiation. The resin is poured into the printer bath into which the printing platform is immersed. Under the printer bath, there is an ultraviolet source and an LCD matrix projecting on the photopolymer layer the image of a section of a part (that is, a product layer to be printed), after which the printer platform rises to the layer thickness and the process repeats.

Source: pressrelease.com

The advantage of such devices is the ability to print objects of a very high resolution; the disadvantage is the obligatory “dirty” post-processing consisting in washing parts off of tar residues, and the need for additional exposure to UV radiation for the final polymerization.

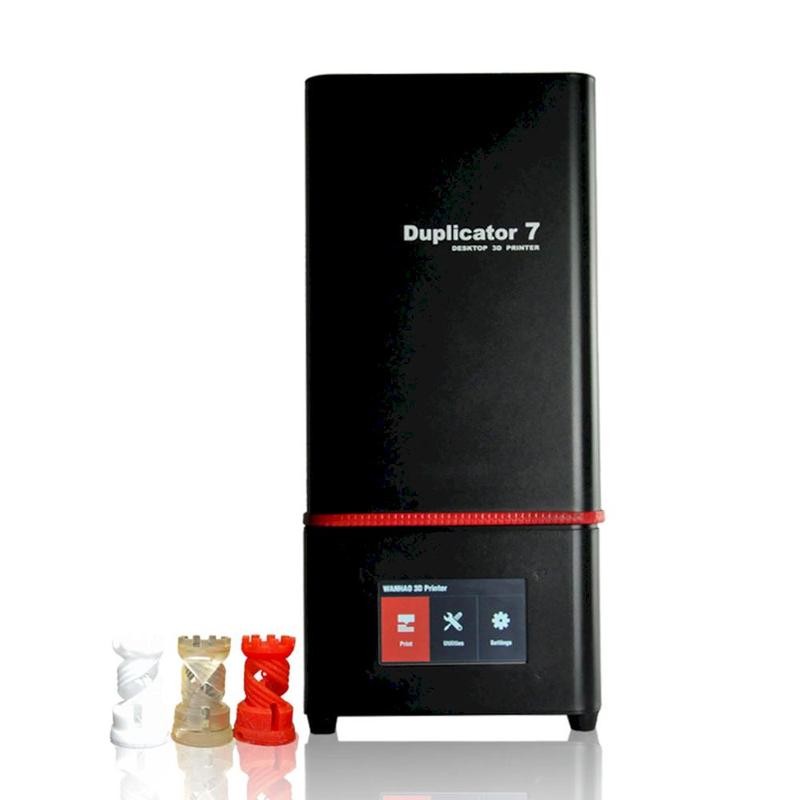

Since its introduction in early 2017, the Wanhao Duplicator 7 (D7) series aroused the interest of 3D printing enthusiasts. The opportunity to get a high-quality photopolymer printer for relatively little money was amazing for the market. So, Wanhao sold a huge number of such printers around the world.

The main advantage of the printer was its price — for a while it seemed incredible, being the cheapest photopolymer device on the market.

The main drawback is that the model does not have a built-in control unit and only works when constantly connected to a computer in which there should not be any third-party applications which could interfere with its operation, that is, with image projection.

An alternative to permanent connection was a special device released a little bit later — the Duplicator Box control unit, allowing the machine to print autonomously. In the next model, which also appeared a little later, it was integrated into the construction and became part of the D7 Plus printer, which you can read about below.

Source: wanhao3dprinter.com

The printer comes fully assembled, so just install the printing platform and pour resin into the bath. Objects to print can be downloaded from a USB stick.

SPECIFICATIONS:

Source: wanhao3dprinter.com

Compared to Duplicator 7, the Plus version has several features:

D7 Plus received a built-in control unit with a touch screen, which allowed it to print and operate autonomously, without connecting to a computer.

The machine is capable of printing up to 30 mm/hour and is equipped with three fans.

The device weighs a little less with the same dimensions.

In general, the Duplicator 7 Plus is positioned by the manufacturer as a solution for professional use; for example, for prototyping jewelry and dentistry, while Duplicator 7 is to be used rather as a hobby machine.

SPECIFICATIONS:

Source: 3dprima.com

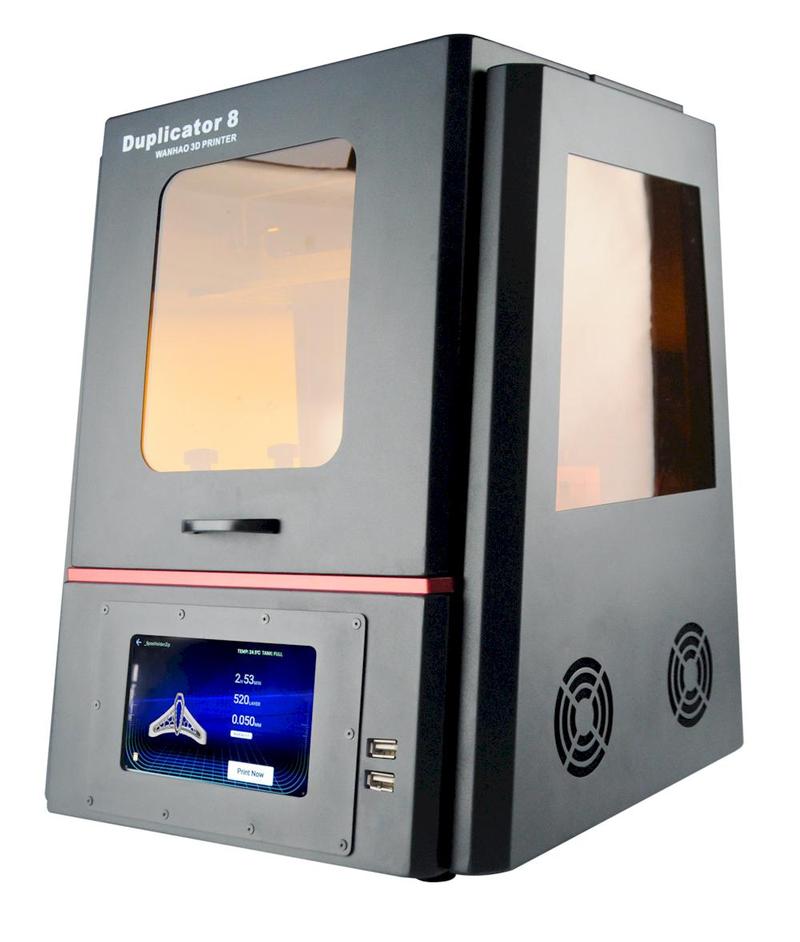

Wanhao Duplicator 8 (D8) is a larger and more advanced descendant of the D7, in many ways not similar to its predecessor. The working area has been increased to 277 x 156 x 180 mm, the hinged cover replaced the removable one, the LCD screen became larger and more convenient. A new intuitive graphical interface has been specially designed for this printer. There is a dual USB connector on the front of the device. Downloading files and operating the printer is possible via Wi-Fi. Cooling is done by two side fans, through the ventilation holes on the back of the machine. The resolution along the X/Y axes is 0.05 mm, with 0.035 mm being along the vertical Z axis. The device will print with any material polymerized by light with a wavelength of 405 nm, which significantly expands the range of photopolymer resins for printing.

SPECIFICATIONS:

Source: wanhao3dprinter.com

When customers choose FDM technology for 3D printing, they are primarily focused on the low cost and ease of use of this technology. FDM is much cheaper than other methods of obtaining 3D models, such as SLS or LCD/DLP, in addition — products can be used almost at once, without any post-processing, immediately after removing supports. The cost of materials used in FDM technology is much lower, and their range is much wider. For this reason, FDM technology, although less accurate, is more attractive to many buyers.

Source: wanhao3dprinter.com

Reliable, secure and affordable 3D printer. It does not have any outstanding abilities of its “elder brothers”, and Wanhao positions it as a printer for teachers, students, and those who are just getting acquainted with 3D printing.

The printer has no platform heating, it does not print with anything except PLA and its composites, being equipped with a fairly small print camera. Yet, it is compact, has a well-thought-out aesthetic design and is easy to use.

SPECIFICATIONS:

Source: wanhao3dprinter.com

The Wanhao D6 Plus features a dual-channel portal system (DTG), which ensures that the printer does not vibrate while moving along the X and Y axes. This improves quality as well as reduces errors when printing at high speed and with the layer thickness of 100 microns. The new MK11 extruder, designed and manufactured by Wanhao, is smaller, lighter and faster to assemble. The clear front panel display simplifies setup and operation. D6 occupies little space and is very quiet.

SPECIFICATIONS:

Source: wanhao3dprinter.com

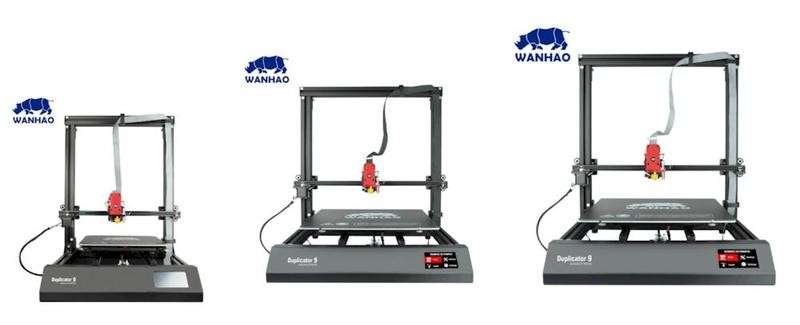

In addition to the huge print area (500 x 500 x 500 mm) for printers in this price category, Wanhao D9/500 has some new features, including high print temperature and direct extrusion. Apart from that, it comes fully assembled. The automatic alignment printing platform enables the device to print immediately after being unpacked. Double guides on the Z axis will completely eliminate the printhead oscillations, and the resume function after a power failure helps avoid defective prints. In this model, all the control electronics, to be safe, are assembled in an additional housing inside the printer itself.

SPECIFICATIONS:

Source: wanhao.store

Boxman is a professional device for photopolymer resin hardening that delivers powerful, stable, focused and uniform UV light. The curing process after printing is necessary to increase the hardness and durability of parts printed. A touch screen for setting the exposure time and a transparent window with the protection from UV radiation make working with the device simple and safe.

SPECIFICATIONS:

Source: amazon.com

"This is my first device to print with photopolymer resin, so far it works great! I didn't upgrade it to v1.5. but with Monocure fast clear I get good results. Height 35 mm, 4 layers are burned for 35 seconds, the remaining layers are after 8 seconds. Looks nice! The operating time is about 1 week,” says Nate.

Source: amazon.co.uk

Mooreis writes:

“A few days have passed, and I'm still satisfied with the purchase. The print results are excellent, the assembly was very simple: only 6 screws. Make sure you align the Z axis with the side guides, not with the platform. The platform itself is easy to align, and prints stick to it perfectly. The platform bearings rub against the straps, but they are easy to replace. The touch screen is large and works alright.”

Source: wanhao3dprinter.com

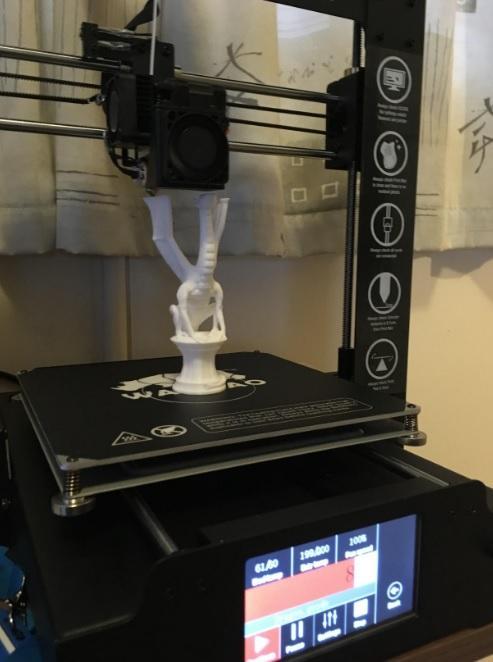

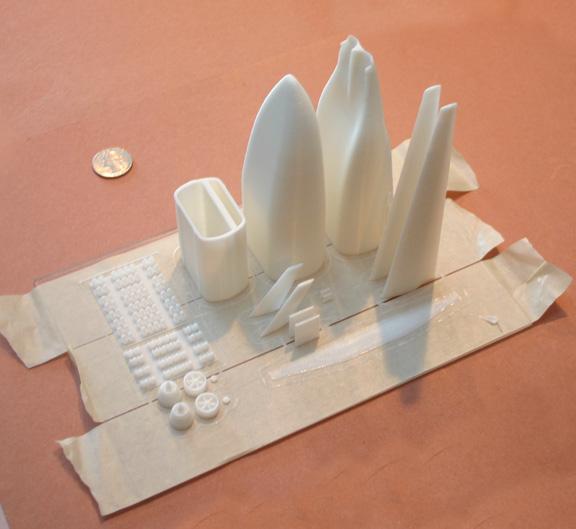

“Popular Science magazine asked me to report on the concept of the NASA/MIT Double Bubble, and I decided to illustrate this model using 3D printing. My work was published in the magazine, along with the placement of a 3D .STL file on a website so that readers or students at school could print in 3D what they read in the magazine,” Dan said.

Source: wanhao3dprinter.com

“When printing with the help of FDM technology, remember that the device applies one thin layer in a single pass. Each layer is approximately the same thickness as a sheet of paper. Since the printer puts a new layer on the previous one, it doesn't like to print in the air, and you either build new layers based on the object itself or have to use additional supports. Most FDM printers allow of the angles of up to 45°. To create this model, I divided the airplane’s body in half to allow the machine to print vertically, leaning on the already printed part. I did the same with the wings.

The problem is how to fix the first layer on the printing platform. After numerous attempts, I found that masking tape cleaned with isopropyl alcohol was great for my material. This model was created using PLA plastic made of corn starch. I don't heat the printing platform and use a nozzle temperature of 205 °C. The nozzle size is 0.4 mm, and the layer height is 0.17 mm. The resulting file was being printed for about 15 hours.”

Source: wanhao3dprinter.com

Source: amazon.com

“Though the Wanhao i3 3D device prints well immediately right out of the box, it took me a few improvements in performance and reliability to really make it a great printer,” writes Alex.

“Here is a list of what I changed:

too noisy fan, replaced with a quiet one;

too large bearing on the X axis rubs against the strap, replaced with a more compact;

Y axis is too flexible, replaced by a stiffer;

electronic stop button is not available on the front cover, fixed;

electronic wire harness is too short, extended;

the bolts of the idler of the X-axis and Y-axis must be longer and have a flare nut at the end. This will tighten the bolt without destroying the retainer or bearing.

I don't regret my purchase and will definitely acquire a new model.”

Source: amazon.com

Source: thingiverse.com

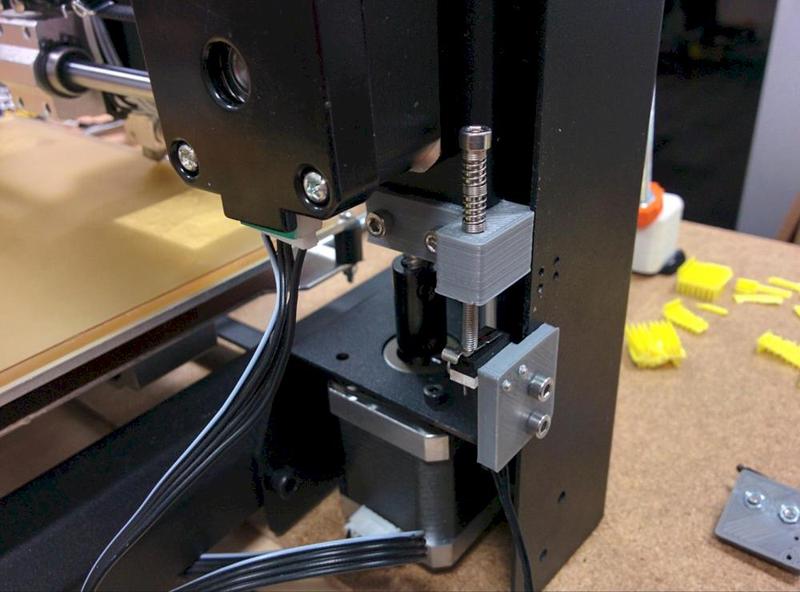

Tim explains the upgrade process:

“Check the position of the M3 holes and drill if necessary. Clean the nut holes and install the nuts. You may need a vice or hammer to insert them. There are five nuts. Add the end cap to the appropriate part by screwing the screws directly into the plastic. By hand, tighten M3x1 to tighten the nuts. As for the lower part, the cut angle goes up, in the direction of the end cap. Look at the photo of this step, you can use a small stack of washers so that it is fixed evenly while you are tightening. The curved corners of the top of the half go together, as in the photo. Add a spring and M3x40 to the top. The spring and the screw head must be aligned with the nut. Clamps! The screws should go straight to the metal edge.”

Source: thingiverse.com

Source: wanhao3dprinter.com

The fate of most successful Chinese startups is almost the same: young people who began their journey by copying already existing more or less good models and went down the path of improving the technology will soon find themselves in the listing of the largest trading platforms and begin selling their products around the world.

It is undoubtedly became possible thanks to the policy of China stimulating the product export and technology import, but the fact remains: Chinese manufacturers do not stand still — they invest in their own developments and innovations. Therefore, now in the global economy it is quite difficult to find products capable of competing with Chinese in terms of the price/quality ratio.

Wanhao is no exception to that, being a confirmation of the golden rule of modern business: “You need to run to at least stay in place.” And what does it take to become a company with a multi-million dollar turnover in just a few years? Apparently, to be tenacious and purposeful "rhino", like Wanhao.

Astronaut Winston Scott receives NASA commemorative badge printed on Wanhao device. Source: wanhao3dprinter.com

Buy an inexpensive and high-quality Wanhao 3D printer at the Top 3D Shop to get an official warranty and the best service possible.

Update your browser to view this website correctly. Update my browser now

Write a comment