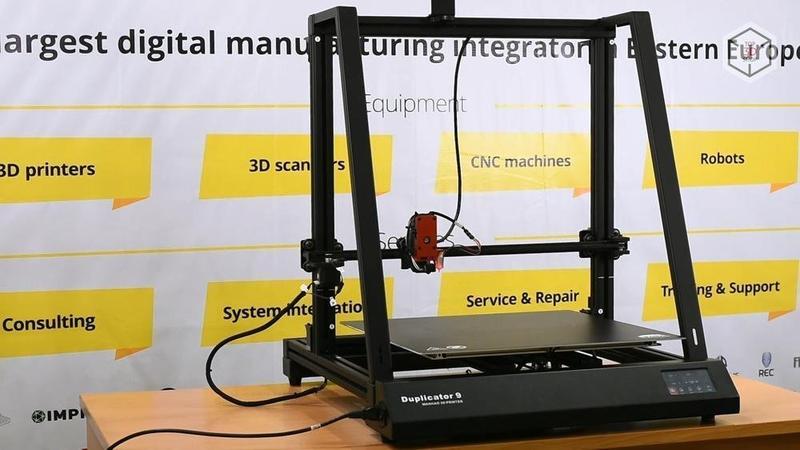

In this article we’ll tell you about Wanhao Duplicator 9/500 Mark II, the machine with the largest build volume among Wanhao 3D printers.

The Duplicator 9 or simply D9 lineup of FDM printers includes models with a large build area. The number in the title indicates the build volume. For the D9/500, it's a cube with a side of 500 millimeters. The smaller options are D9/400 with a build volume of 400x400x400 mm and D9/300 - 300x400x400 mm.

The frame of the printer is made of aluminum profile 20x20mm. To increase the strength and rigidity of the structure, the manufacturer installed two additional supports on the sides. This happened after numerous complaints about low rigidity of the previous model.

Wanhao Duplicator 9/500 kinematics is standard for the company's FDM printers. The bed travels along the Y axis on the belt drive. The extruder moves along the guides on three rollers - along the X and Z axes.

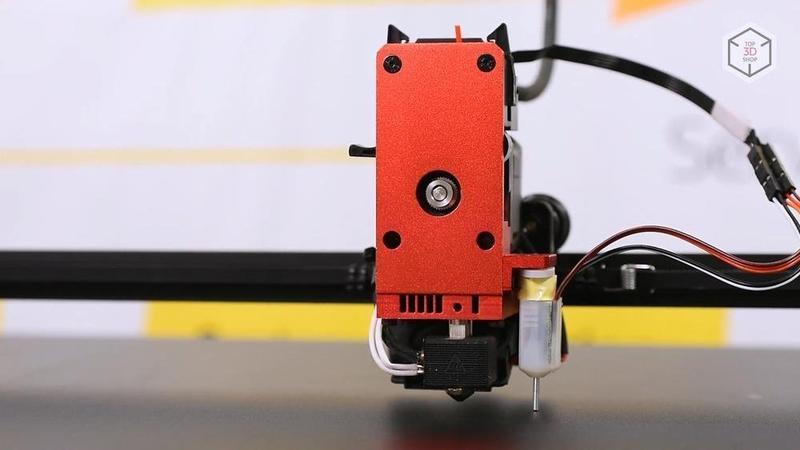

The printhead, with direct filament feed and the all-metal MK10 hot end can heat plastic up to 300 degrees, which expands the range of materials available for printing. With all the advantages of this extruder, the feed rate is low and limited to 70 mm/sec. The cooling fan, thanks to the ability to adjust the performance, provides the optimal temperature for printing with any available filament. The minimum layer thickness is standard for Wanhao printers - 100 microns.

It is recommended to use a touch screen to configure and control the printer's operating modes. Large interface elements simplify interaction with the device.

The Resume Print system, which will remember all the information about the print and the position of the extruder, will prove particularly useful in the event of a power failure. This feature is especially helpful when manufacturing large objects.

The main difference between the Mark II and the original D9/500 is its supports and a double aluminum profile along the Y axis, reinforcing the rigidity of the entire structure. This solution significantly improves stability and print quality.

The manufacturer claims that the smoothness of the bed movements along the Y axis was improved by increasing the number of rollers on the rails from three to four, the system for fixing wires was improved, and the cooler was modernized.

The D9/500 now features the BLTouch electromechanical auto-leveling sensor. The printhead independently passes through several points - the printer saves the received data and takes it into account when printing.

The Mark II, an updated version of the original D9/500, comes partially assembled. The package contains: the base with a print platform, the X axis construction with a pre-installed extruder, an aluminum profile for assembling the U-shaped frame, and two supports.

Besides that, the package contains:

The assembly and setup time of the 3D printer depends on the user's experience. The whole process usually takes about 1.5-2 hours.

The assembly of the printer is simplified by the tags and stickers with numbers placed on the components.

To simplify the process even further, check out this video:

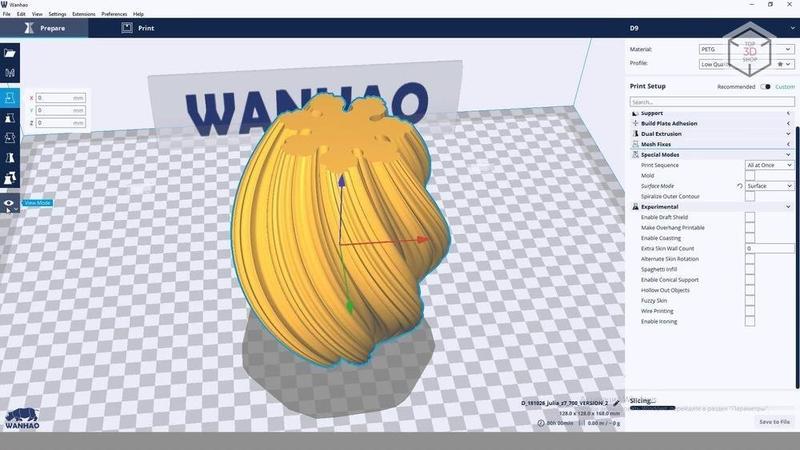

The printer comes together with software. To prepare digital models for printing, the manufacturer recommends Cura Wanhao Edition. This piece of software has a wide range of settings, sufficient for printing most models. You can use it to set the speed and temperature of printing, layer thickness, density, set the diameter of the nozzle, if necessary - place the supports.

The finished file with the g-code can be transferred to the D9 / 500 memory using an SD card or via USB. The Mark II version has a special little drawing near the port. Now confusing the sides of the SD card is impossible.

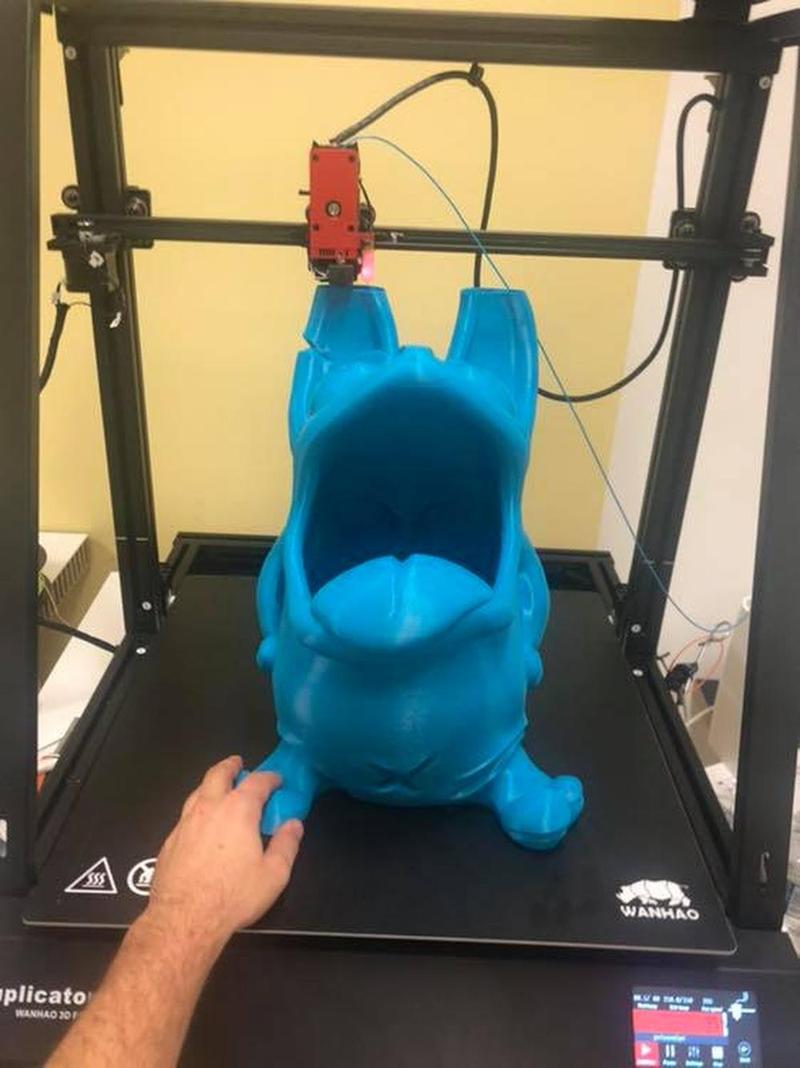

Source: www.facebook.com

Workers in the French division of Wanhao printed a 47 centimeter high model in just one go. This is almost the maximum possible size for the D9.

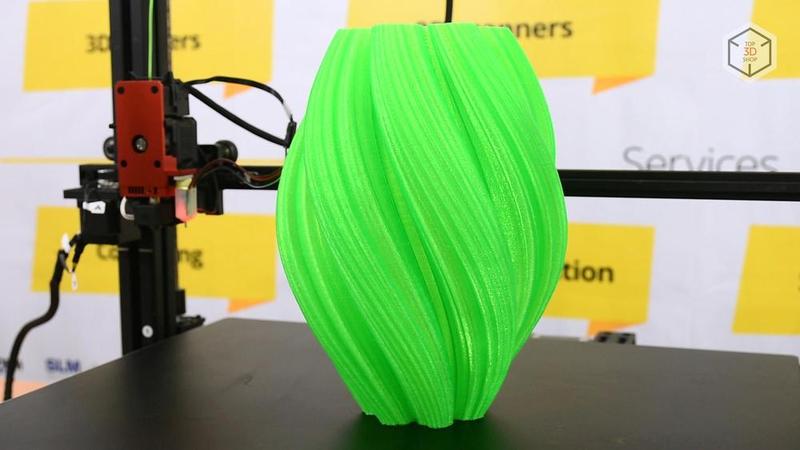

An owner of a Wanhao D9/500 Mark II 3D printer created a complex vase made of white filament.

Pros:

The largest build volume among Wanhao printers;

Improved, more rigid design;

A wide selection of materials due to the heating of the extruder up to 300 °C and a heated bed;

Easy assembly and calibration;

Ability to continue printing after blackout;

Touch screen.

Cons:

Relatively low printing speed - 70 mm/s;

No enclosure, the issue is solved by installing a home-made enclosed cover;

Some users reported deformation of the bed during overheating.

Wanhao Duplicator 9/500 will be perfect for makers, engineers, designers, advertising agencies - all those who require large-sized printing. The improved version is devoid of the main disadvantages of the previous model, the only significant disadvantages are the low printing speed and the absence of enclosure. The rest makes it a great solution for printing large models in one go, instead of having to glue together the parts of a single model.

Contact us to purchase Wanhao Duplicator 9/500 and get any help and maintenance you require.

Update your browser to view this website correctly. Update my browser now

Write a comment