[CASE] 3D Printing in Architecture by the Example of Setl-City

3D Printing in Architecture

Long gone are the days when 3D printing was a toy for geeks and a prototyping instrument. Today, professionals from dozens of industries apply to such equipment.

Among our customers there are many companies operating in a wide range of fields — from dentistry and jewellery industry to performing arts and exhibitions. In this material, we consider the use of 3D printing from the standpoint of a building contractor.

One of the Company's projects

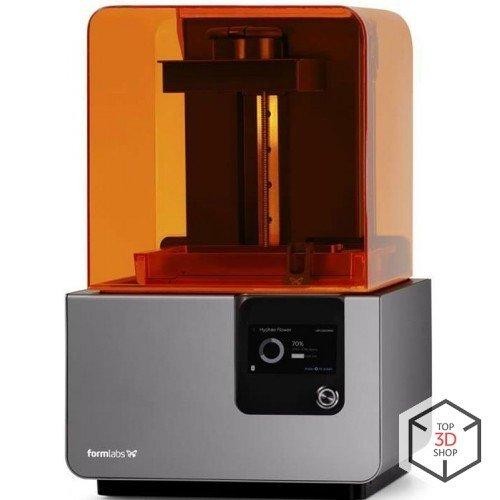

We asked a staff member of Setl City, one of the leading Russian manufacturers, a number of questions. The Company purchased a Stereolithography 3D printer Form 2 from us.

- Technology: SLA

- Process chamber: 145 x 145 x 175 mm

- Layer thickness: from 25 microns

- Price: on request

We share the results of this conversation with our readers. This is what we found out.

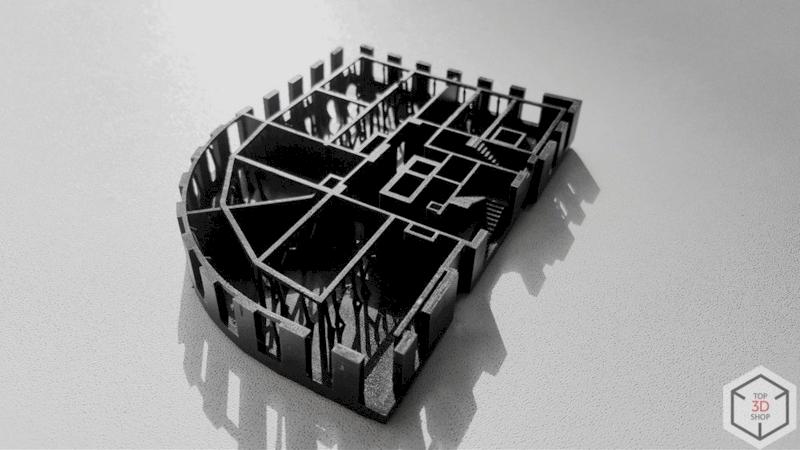

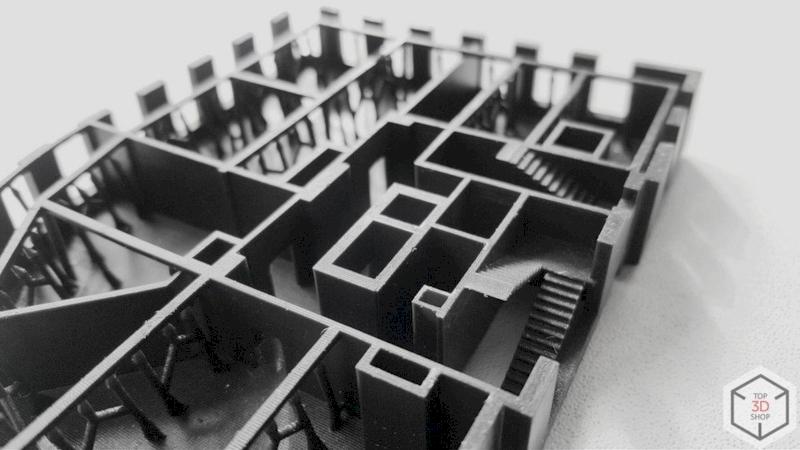

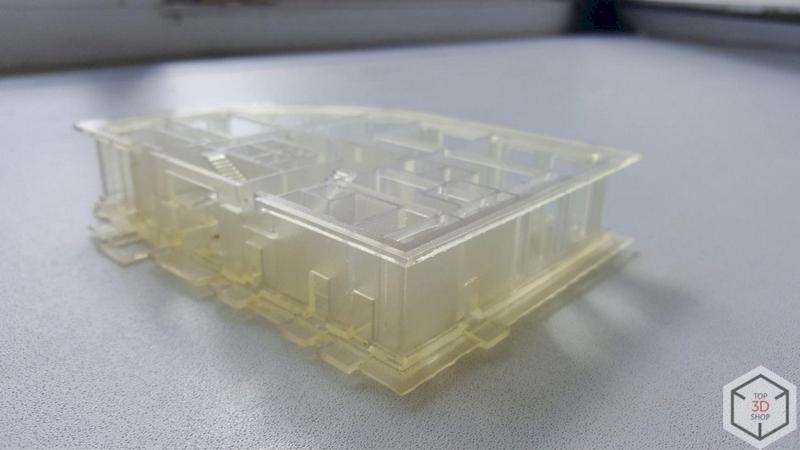

One of the Company's projects

Goals

3D printers are widely used by developers for the following purposes: creation of elements of large-scale building models and modeling of houses with due account for interior space allocation. Both are applied in the course of construction planning and for presentations.

“The primary purpose of buying a 3D printer was to figure out whether to use this technology in the Company’s operations – on a large scale and on an ongoing basis.”

One of the company's projects

How It Was Before

Without the assistance of 3D printing technology, such tasks were solved in the old manner: architects constructed building models with their own hands. It was not always justified for financial reasons, as the architect's working time was not cheap and the process of modeling required quite a lot of time and technique. Long-lasting manipulations with paper, foam, and plastic could hardly motivate professional modelers to success. Involvement of students and other third persons, however, frequently led to reduction in the quality of building models.

Today, there are model-making workshops and architectural bureaux, but their services are quite expensive and it is not always possible to introduce changes to the order on a timely basis.

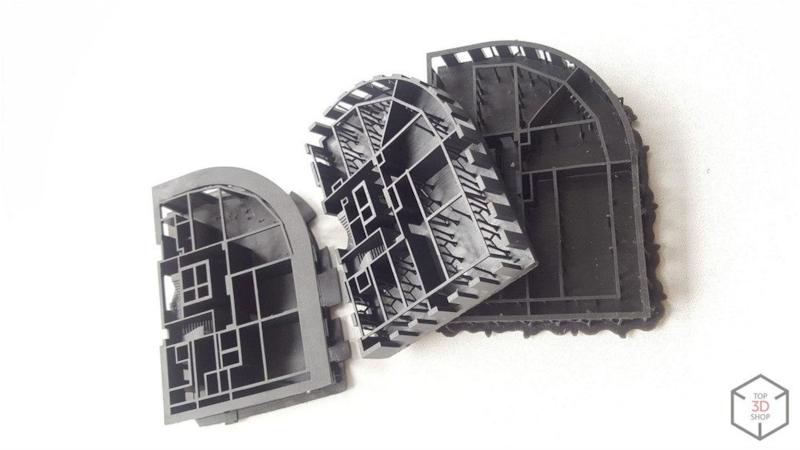

3D printed model

Why Form 2

Actually, stereolithography delivers better quality of 3D printed objects as compared to FDM technology. We decided to implement the Formlabs Form 2 3D printer in our work, as it provides the required quality of printing and operates without a hitch. It is a time-tested and reliable model from a trusted manufacturer.

How Printer Was Used and How It Proved Itself

The printer was used for the creation of building models with all internal structure – floors and stairs. The models turned out accurate and high grade. It would have taken much time and effort to build such a maquette by hand.

“We were pleasantly surprised by the quality of printed surfaces and the accuracy of proportions. The models turned out really great.”

3D printed model

Setl City is not yet ready to make a photopolymer 3D printer part of its technology process, as stereolithography printing requires much time and high quality digital models; the latter should be created by an individual professional.

“We would like to print with several colors at once, but it's impossible in case of stereolithography. We don’t like the procedure of post processing – it takes additional time, quite sizeable in our case. Besides, there is a lack of an ‘intelligent stop’ system for the event of an unsuccessful printing – it would be great if the printer could identify waste and stop the printing process.”

3D printed model

Resume

Nevertheless, the use of a 3D printer delivered certain benefits, displayed the opportunities of new technologies to the Client, and gave pause for thought.

“Indeed, the use of a 3D printer did good for us: we got an insight into how and in which tasks we can implement this technology. Besides, it helped us give a budget estimate of costs and work efforts for the designing and printing of architectural models. It is good to know for the future.”

3D printed model

We appreciate our cooperation with Setl City and remind readers that the specialists of Top 3D Shop are always ready to provide consultation on the issues of choice and use of 3D printers for different purposes.

![[CASE STUDY] 3D printing in Erarta museum of contemporary art](https://top3dshop.com/image/cache/catalog/blog/stigmashowandtheirraise3dn2dual3dprinter/main4-494x216.jpg)

![[CASE STUDY] 3D Scanning of an Electric Car as a Part of the R&D Process](https://top3dshop.com/image/cache/catalog/blog/review_1/3d_scanning_of_an_electric_car/image_1-494x216.jpg)

![[CASE STUDY] 3D Tech in Architectural Prototyping](https://top3dshop.com/image/cache/catalog/blog/review_2/3d_tech_in_architectural_prototyping/image_39-494x216.jpg)

![[CASE STUDY] 3D Scanning of Original Masks](https://top3dshop.com/image/cache/catalog/blog/review_2/3d_scanning_of_original_masks/image_101-494x216.jpg)

![[CASE STUDIES] Printing of Complex Airport Models](https://top3dshop.com/image/cache/catalog/blog/review_2/printing_of_complex_airport_models/image_55-494x216.jpg)

Write a comment