[CASE STUDY] Kreotech: Robots, 3D Printers and CNC Centers in Electronics Production

Rapid prototyping is one of the booming concepts of the Fourth Industrial Revolution. Industry 4.0 requires the acceleration of technological processes and the reduction of technological chains. With 3D equipment and robots becoming ever-more affordable, the number of businesses that adopt rapid or functional prototyping is growing as well.

Kreotech is a St. Petersburg-based company that specializes in the creation of electronic equipment. This year, we have provided them with several devices to help engineers significantly reduce the development time.

Read on to learn more about how robots, 3D printers, and CNC machines aid in the development and production of electronics.

About the company

Kreotech is engaged in the full cycle of electronic equipment manufacturing — from the coordination of technical requirements with a client to serial production.

The company performs orders for civilian enterprises, including agricultural and defense industries. Its main scope of activity involves security systems, industrial and telecommunications equipment, augmented reality.

Not only does Kreotech work with routine orders, which include the development and production of industrial equipment control systems as well as those for diagnostics and data collection of industrial networks — the company's projects also include augmented reality glasses, a video processing and machine vision system, industrial cameras.

According to the executives of Kreotech, the company is a "developer of non-standard solutions" focused on fabless manufacturing.

Fabless manufacturing is a business organization model in the electronics industry, with which the manufacturer specializes only in the development and sale of microelectronics but doesn't have its own production facilities. That is, it employs the services of OEM enterprises to manufacture products.

Equipment

All the equipment from Top 3D Shop was acquired to accelerate prototyping and mastering new technological processes.

Hanwha HCR-3

Specifications

- Degree of freedom: 6 rotating joints

- Payload: 3 kg

- Reach: 630 mm

- Linear speed (typical): 1m/s

- Weight: 13 kg

- Repeatability: ±0.1mm

- IP level: IP64

- Joint range: J1, J2, J4, J5: ±360°; J3: ±160°; J6: Infinite

- Price: on request

One of the company's new acquisitions is the Hanwha HCR-3 collaborative robot. Kreotech admits that the device was purchased to test the possibility of integrating cobots into technological chains related to framework.

Engineers have yet to find out how robotic arms are applicable for the implementation of the company's tasks and whether it is possible to fully adapt them to the planned technological processes.

Raise3D Pro2 Plus

Specifications

- Technology: FDM

- Extrusion type: Dual

- Nozzle diameter: 0.2/0.4/0.6/0.8 mm

- Filament diameter: 1.75 mm

- Extruder temperature: 300 ºC

- Bed temperature: 110 ºC

- Build volume: 305 x 305 x 605 mm

- Min. layer thickness: 10 µm

- Printable materials: PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG, ASA, PP

- Software: IdeaMaker

- File formats: STL, OBJ, GCODE

- Price: $5,999.00

Kreotech uses the Raise3D Pro2 Plus FDM printer for the fast and relatively inexpensive production of working prototypes, “drafts”.

When choosing an FDM printer, the company, among other things, was guided by financial considerations: it was agreed to focus on a universal solution that could be used both for creating large-sized products and printing small components.

As a result, Kreotech engineers considered Picaso and Raise3D equipment — and decided on the latter.

Sinterit Lisa Pro

Specifications

- Technology: SLS

- Laser system: IR laser diode, 5 W, class 1

- Layer thickness: 75–175 µm

- Min. wall thickness: 0.4 mm

- XY accuracy: 50 µm

- Materials: PA11, PA12, Flexa

- Print bed size: 150 x 200 x 260 mm

- Chamber temperature: 192 ºC

- On-board camera: Built-in

- Connectivity: Wi-Fi, USB

- Display: 7” color touchscreen

- Operating systems: Windows, Mac OS

- Outer dimensions: 690 x 500 x 880 mm

- Weight: 90 kg

The Sinterit Lisa Pro SLS printer was obtained for preparing the final versions of products, that is, those ready for being sent to mass production, as well as for the manufacture of functional prototypes.

The model by the Polish manufacturer turned out to be the most affordable one at the time (the end of 2019), being an optimal solution in terms of the capabilities/price/quality ratio.

Raylogic 11G 1620

Specifications

- Type of laser: CO2

- Capacity: 100W

- Engraving/cutting field size: 1600 x 2000 mm

- Engraving accuracy: 0.01 mm

- Engraving speed: 800 mm/s

- Connectivity: USB 2.0

- Cooling: Water chiller (freon)

- Power supply: 220V

- Max. power consumption: 2.5kW

- Outer dimensions: 2600 x 2100 x 1100 mm

- Weight: 920 kg

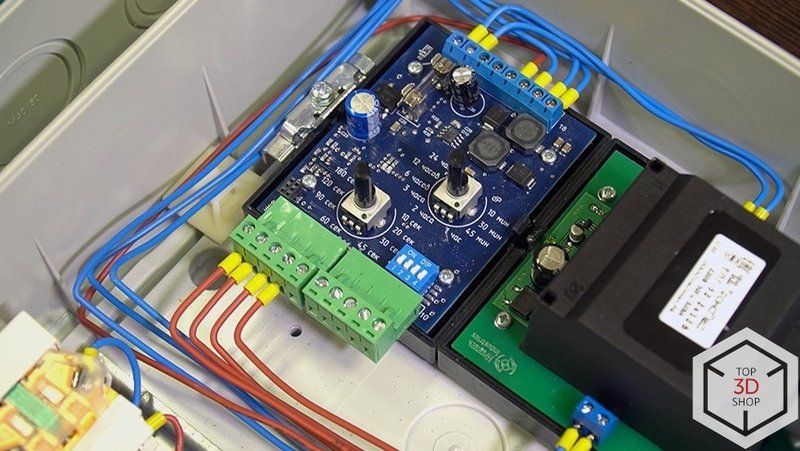

Another area in which the company is engaged is the assembly of switchboard equipment of non-standard sizes. Sometimes the customer requires a dense arrangement of elements inside the product, and the ready-made options available on the market do not meet this requirement.

The Raylogic 11G 1620 laser system was chosen for cutting sheet metal and engraving on metal components. The working area allows for the production of boxes of various dimensions.

Advantages and benefits

Prior to acquiring its own set of 3D equipment, Kreotech resorted to prototyping by subcontractors. The company was not always satisfied with the speed of execution of outsourced orders, even if the quality of the performance was high enough.

The Kreotech executives say that sometimes deadlines could be delayed for weeks while the preparation of a prototype was to have been finished within one to three days.

Kreotech's engineers mastered the equipment and achieved the required quality of samples, comparable to that provided by subcontractors.

The execution time has been minimized, since there is no need to send an order to the contractor and wait until it is accepted for printing. In addition, design engineers can save their working time as they no longer have to act as a courier when receiving finished products.

Conclusion

With the right selection of the necessary technologies and specific models, robots and 3D equipment can significantly speed up even the most advanced technological processes.

Rapid prototyping by means of additive technologies considerably saves the time required to complete a task — from getting a technical assignment to creating a functional prototype. And given the on-going decline in the cost of 3D equipment, updating and increasing the efficiency of technological chains is becoming still more affordable and profitable.

![[CASE STUDY] 3D printing in Erarta museum of contemporary art](https://top3dshop.com/image/cache/catalog/blog/stigmashowandtheirraise3dn2dual3dprinter/main4-494x216.jpg)

![[CASE STUDY] 3D Scanning of an Electric Car as a Part of the R&D Process](https://top3dshop.com/image/cache/catalog/blog/review_1/3d_scanning_of_an_electric_car/image_1-494x216.jpg)

![[CASE STUDIES] Printing of Complex Airport Models](https://top3dshop.com/image/cache/catalog/blog/review_2/printing_of_complex_airport_models/image_55-494x216.jpg)

Write a comment