Versatile FFF/FDM printers with a rather large build volume are rare among the lower-priced machines. The latest technological advancements have allowed such devices to exist. The Creality CR-10S Pro is one of those machines — it combines a large print volume and several useful features at an affordable price.

Source: creality3dofficial.com

The CR-10S Pro is another addition to the ever-evolving CR-10 series. This device tries to do three things at once: to be feature-packed, provide a rather large build volume, and to be affordable. This is a 3D printer that can be used by both experienced users and beginners. The former will appreciate the various high-tech features, while the latter will enjoy the ease of use that is neatly combined with an affordable price.

Source: creality.com

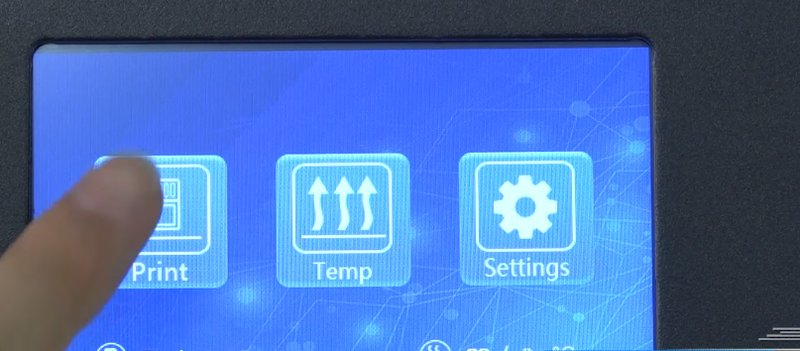

The CR-10S Pro provides the closest thing to an automatic bed leveling among Creality’s 3D printers at the time of its release. The height of 16 points of the print bed is automatically measured, and the user is assisted during each step of the process. A 4.3-inch touchscreen allows for easy navigation of the device’s abilities, including the leveling. Its UI is rather intuitive, consisting of large icons that provide fast access to the features.

The machine features a double-gear extruder. The system is of a Bowden style. Together with a high-quality feeding tube, the whole mechanism provides accurate feed rates, a smooth extrusion, and the ability to withstand extremely high temperatures. This means that there are more materials supported than is usually expected from a device of this price range. Even high-performance ones such as TPU and carbon fiber are listed by the manufacturer, so the CR-10S Pro is very versatile.

Other important features include a newer V 2.4 control board that provides a better stepper control and a significant noise reduction — the manufacturer claims that the machine is very quiet, a filament runout sensor, and the ability to resume printing after power failure. Last but not least, there is a print bed that can reach the temperatures of up to 110 °C within 5 minutes.

Source: youtube.com

The CR-10S Pro comes as a DIY kit in a large box. Everything is safely packaged.

Source: youtube.com

The contents include an upper frame part, the base of the device (including the platform), a toolbox (with cutters, cables and other stuff), around 200 grams of filament and an instruction.

Source: youtube.com

The picture below also shows what’s inside the toolbox.

Source: youtube.com

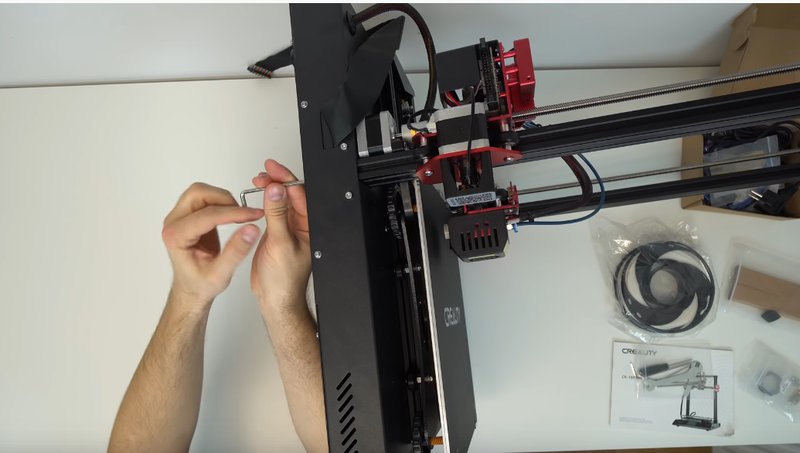

Even though the device comes as a kit, it’s not difficult to assemble it and the process doesn’t take a lot of time (around 10 minutes).

You can assemble the device in just a few easy steps.

The first thing to do would be to place the top frame on the base and tighten the screws on the bottom (two on each side).

Source: youtube.com

Source: youtube.com

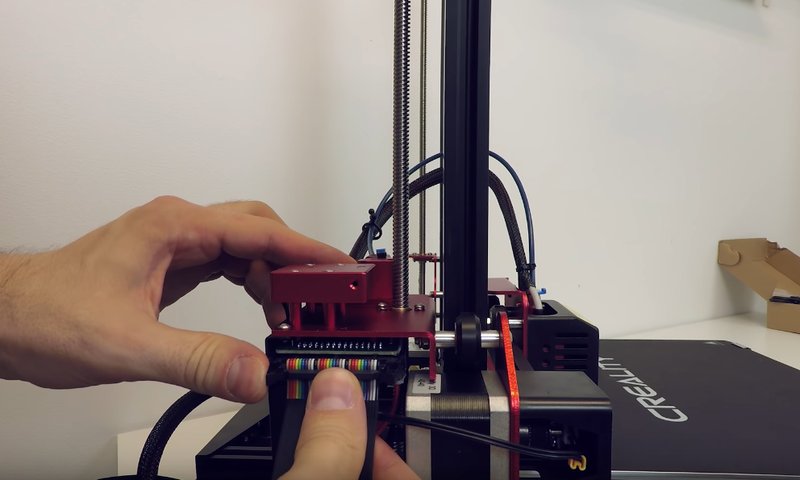

The next step requires to plug in the Z step and motor cable, as well as a large ribbon cable.

Source: youtube.com

Source: youtube.com

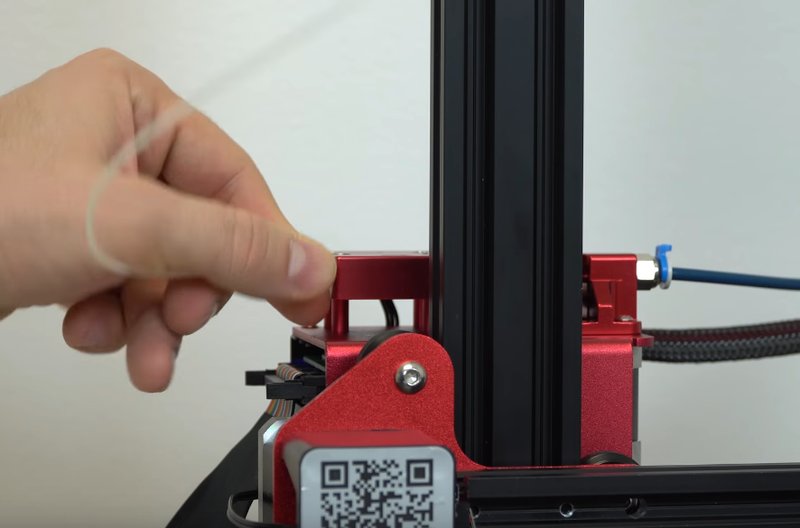

Then you install the filament holder and load in the filament.

Source: youtube.com

Source: youtube.com

Source: youtube.com

Plugging the power cord and starting the printer would be the last step.

Source: youtube.com

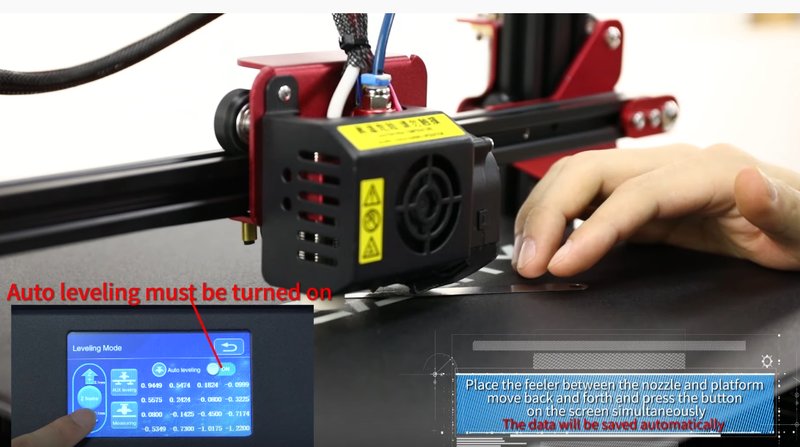

After assembling the printer and turning it on, leveling the bed would be the first logical step. Click on the ‘Settings’ button in the main menu, then go to ‘Leveling’.

Source: youtube.com

Check that the ‘Auto Leveling’ feature is on, place the feeler between the nozzle and the platform, move it while controlling the ‘Z home’ feature in the menu.

Source: youtube.com

Then you can try to test the extrusion and if everything works, go to the ‘Print’ option in the main menu and try to test print some files (provided the SD card with the files is inserted).

Source: youtube.com

The printer is compatible with the most common of slicing and host software, including Cura, Simplify3D and Repetier-Host. Some programs already have pre-installed profiles for the device.

Instagram user herculeflambeau has printed a small action figure of Star Wars character named ‘The Child’ (known over the Internet as ‘Baby Yoda’), using a 3D design by Rober Rollin. The model was printed on the Creality CR-10S Pro.

This is the model before being painted. Look how detailed it is. The surface finish is quite impressive.

Source: instagram.com

And here’s the final painted result:

Source: instagram.com

This work is a great showcase of the CR-10 Pro’s abilities to print large-volume models with a high detail and great finish. This is a final result of an incredibly complex print that took 112 hours to complete.

Source: instagram.com

The picture below shows the test print of a CR-10S Pro user. Printed at a 200-micron layer height this horse model looks quite impressive, showcasing smooth surface finishes that are not easy to achieve at this layer height.

Source: cobnut3d.co.uk

Source: instagram.com

Pros

Cons

It looks like the Creality CR-10S Pro was designed with versatility in mind. It’s an inexpensive printer with the build volume large enough to print sizeable models and experiment a bit with some interesting objects. It’s also easy to use with a large touchscreen and a very intuitive and minimalistic UI, which will be appreciated by both beginners and professionals alike. The device is very easy to assemble and features an automatic bed leveling, so it’s not lacking convenient features. Safety measures include filament runout sensor and the ability to resume printing after power failure. The device is able to achieve a good quality of printing and supports many different filaments, including even the demanding ones such as TPU and carbon fiber. This ability to use various materials is possible due to high temperatures that can be achieved by the nozzle and the print bed.

The caveats include some quality control issues experienced by some users and minor printing defects which are nothing out of the ordinary for such printers. The lack of enclosure might be a problem for some, but good ventilation and safety measures make up for that. For those willing to spend more money, there are mods and separate enclosures available.

The CR-10S Pro is a good device that has enough high-tech features, is easy to use, has a decently sized build volume and doesn’t cost a fortune.

Update your browser to view this website correctly. Update my browser now

Write a comment