Hello and welcome to Top 3D Blog, your trusted source of quality additive manufacturing content. In this addition, we are going to break down the optimal workflow for 3D printing with PLA. You can learn more about all the necessary settings, pros and cons of printing with PLA, find solutions for the most common printing issues, and check out a number of fascinating use cases by reading this article. Let’s dive right in.

Source: wikimedia.org

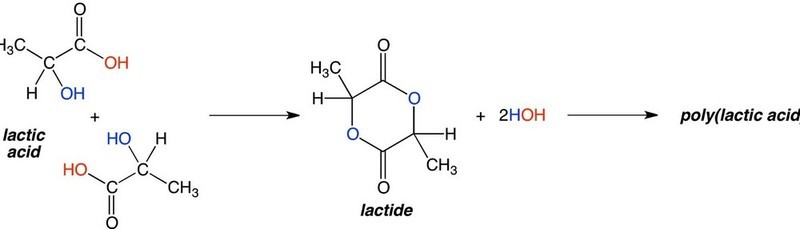

Polylactic acid or polylactide (PLA) is a biodegradable and biologically active polyester that consists of lactic acid molecules. The material was discovered in 1932 by Wallace Carothers, an American chemist, during his attempts to produce a polyester with a molecular weight of above 4,000 by heating lactic acid in a vacuum and removing condensing water.

The production of lactic acid on an industrial scale is cheap, besides, it employs renewable green resources since carbohydrates are taken from raw materials such as corn starches and sugar canes. Another important advantage of this technology is that the total greenhouse gas emission in the case of industrial-scale PLA production is considered negative because during the recultivation of required plant materials large amounts of carbon dioxide are consumed.

Source: 3dinsider.com

In the past, PLA has mainly been employed in the field of biomedical research due to its biocompatibility and biodegradability. However, innovative manufacturing solutions and increased environmental awareness considerably increased the popularity of eco-friendly materials. That’s why nowadays PLA is widely used as a packaging material and is considered to be the most popular filament for 3D printing.

Source: newatlas.com

PLA is a thermoplastic material that can repeatedly undergo melting and hardening without losing its properties. Depending on the structure of lactic acid molecules that constitute a particular piece and its properties, PLA can be divided into the following categories:

The main properties of PLA are:

Moreover, PLA is soluble in hot benzene, tetrahydrofuran, and dioxane.

Source: 3djake.com

The main advantage of PLA is that it is an eco-friendly, easy-to-print, and biodegradable material manufactured from renewable resources. Besides, PLA-based details are stable under normal conditions, food-safe, and, all in all, perform just like parts made from polyethylene (PE), polypropylene (PP), or polystyrene (PS).

Its disadvantages include high hygroscopicity and relatively low heat resistance. The products made from pure PLA are also fragile, that’s why filament manufacturers employ various additives to reinforce their printables and improve their impact and chemical resistance.

Source: 3dprinting.stackexchange.com

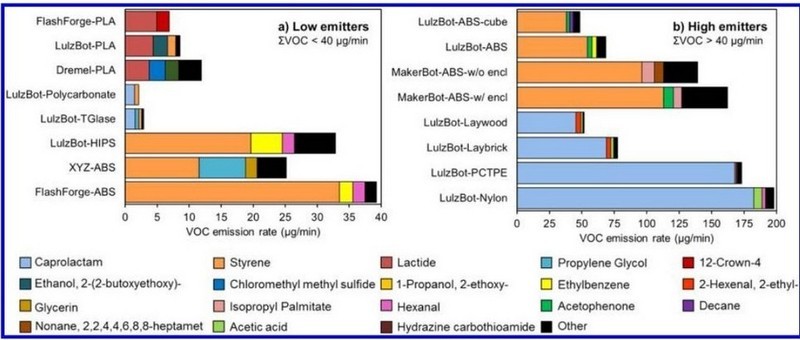

The “Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments” research states that PLA-based filaments feature particularly low gas emission and that the main gas released during 3D printing is lactide, which, in its turn, is non-toxic. Nylon, for instance, accounts for 19 times the amount of emitted gases as compared with PLA. Nevertheless, the filament may include other manufacturer-specific compounds and dyes, so it’s imperative to always use your 3D printer in well-ventilated premises in accordance with electrical and fire safety standards.

Source: bitfab.io

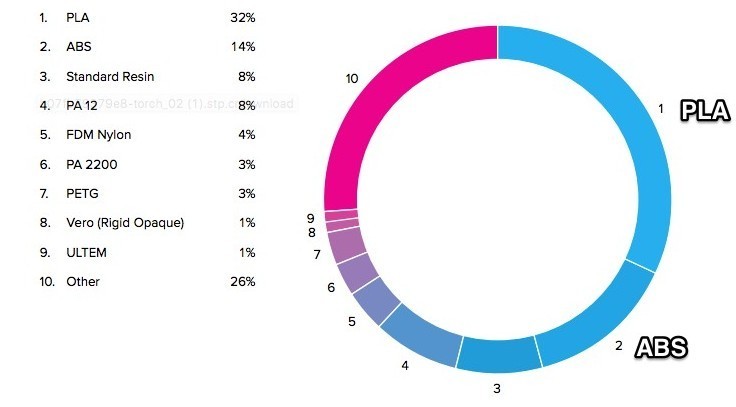

According to the 3DHubs Trend Report Q4/2017, PLA is considered the most popular printing material that makers employ on their FDM/FFF 3D printers. And it comes as no surprise since this eco-friendly material is really easy and safe to print.

Source: makerbot.com

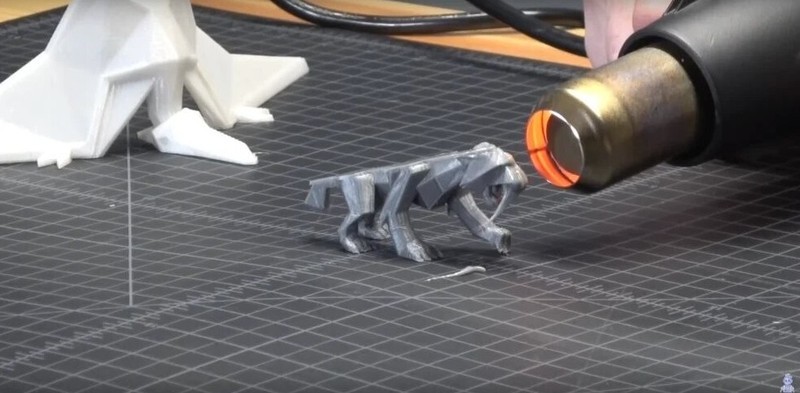

Another advantage of PLA is that it melts at just 180°C and doesn’t require a heated bed let alone a fully enclosed build chamber, letting you print even on entry-level 3D printers. On the contrary, you won’t be able to reliably print with ABS if your printer is not equipped with an extruder that can heat up to 250°C, a heat bed, and a fully enclosed build chamber. Besides, PLA-based parts are incredibly easy to post-process and can also be drilled and milled. Be careful not to melt them though — all manipulations must be carried out without heating up the cutting tool.

Source: wanhao3d.ru

As we have already mentioned, PLA-based filaments are hygroscopic, so they have to be stored in tightly sealed packages. Besides, filament spools can be degraded by moisture if they are left open for too long. That’s why using a filament dryer before proceeding to the actual printing process would always be a good idea.

Thankfully, your 3D printer doesn’t have to be equipped with a heated bed or feature an enclosed print chamber in order to reliably print with PLA, because this material is not susceptible to deformation and delamination that can be caused by temperature changes.

To ensure optimal first layer adhesion, we recommend using glue sticks, “extreme hold” hairsprays, and special coatings like the ones offered by Kapton or BuildTak. Moreover, print the first layers at minimal speed and increase the model’s area by using a “raft”.

Source: all3dp.com

The given settings are not optimal and strongly depend on the type of 3D printer and filament employed. The best way to select optimal printer settings would be to carry out a test print.

Moreover, make sure that the extruder cooling fans are operating during printing. Keep in mind that the cooling must be disabled when printing the first layers to achieve the best layer adhesion possible.

Source: all3dp.com

Despite the toughness and strength of PLA that lets you print models with overhangs that can tilt up to 70° angles, it is necessary to reinforce your models with support structures. The supports can be printed with either PLA or water-soluble PVA-based solutions that are incredibly easy to remove.

Use sanding paper and polishing pastes to provide your model with a refined outlook. Even though you won’t likely achieve a completely glossy surface finish, your model will look a whole lot better.

PLA is soluble in isopropyl alcohol, letting you benefit from the usage of special smoothing devices like Polymaker Polysher that create a mist of solvent inside the sealed chamber for quick and easy one-step smoothing.

On the other hand, you can use plastic polishing compounds, or simply paint the created part with acrylic paint or enamel.

You can glue different PLA-printed parts together by employing dichloroethane, dichloromethane or isopropyl alcohol to dissolve external plastic layers and create sticky surfaces. In addition, you can just use superglue or epoxy/polyurethane compounds.

Most of the first layer issues are caused by insufficient layer adhesion that leads to the detachment of a printed part or its displacement. To fix this, try increasing the hotbed temperature in case your device features this option. In case it does not, cover the build plate with an adhesive solution (ultra-strong hairspray/glue stick/ special coating). Don’t forget to reinforce the adhesion level by adding a 3D printing raft and increasing the area of the first layer.

Source: pinshape.com

Stringing appears due to excessively high extruder temperature that causes the filament to become too fluid. Then, the force of gravity makes the material flow out of the nozzle, creating webs and strings in places where the printer was not even supposed to print.

To deal with the issue, decrease the extruder temperature and turn on the retraction — a very useful feature that prevents the dripping of excess material during the extruder movements.

To deal with delamination you should simply increase the extruder temperature until the problem is fixed. If the problem still appears, try decreasing the printing speed.

Source: pinshape.com

Since PLA-based filaments have a relatively low melting point, small-scale PLA parts oftentimes do not have enough time to cool down and harden. Additionally, they are continuously heated by the print head that is always in close proximity.

To solve the problem, reduce the printing speed and decrease printing temperature. Moreover, make sure that the printed part is cooled properly during printing and that the airflow does not enter the extruder.

Source: wikipedia.org

Source: all3dp.com

Source: all3dp.com

Source: all3dp.com

Source: fabb-it.com

Source: fabb-it.com

Source: zortrax.com

PLA is a budget-friendly material that is incredibly easy to print with. It is perfect for both entry-level makers and professional users. Thanks to being eco-friendly, biodegradable, and renewable, we can expect all petroleum-based plastics to be replaced with their PLA-based counterparts in the nearest future. Besides, this 3D printing material is safe and non-toxic, letting you benefit from employing it in home workshops and educational institutions as well as in the medical, food, and other industries.

You can purchase PLA 3D printer filaments from Top 3D Shop. Our team will provide you with the best service possible, just like we always do.

Update your browser to view this website correctly. Update my browser now

Write a comment