Hi everyone! This is Top 3D Shop, and in the following review, we will talk about 3D printing with ABS filament, recommended settings for popular 3D printers, possible problems, and use cases. Find out more about the features of this material from our article.

Source: wikipedia.org

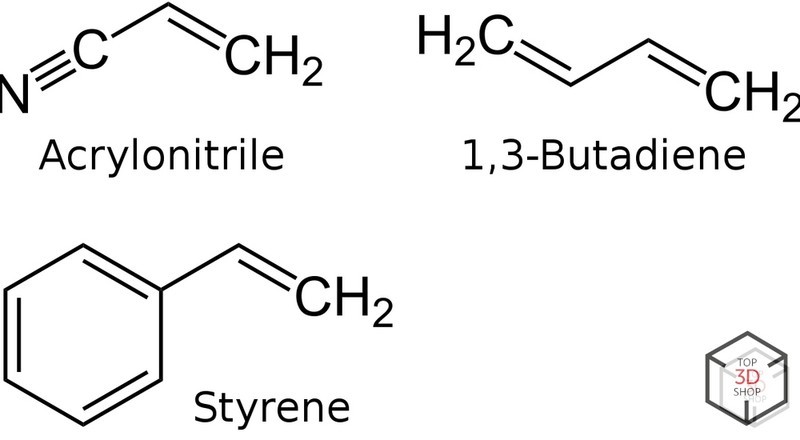

ABS plastic (ABS), acrylonitrile (15–35%) butadiene (5–30%) styrene (40–60%), — the chemical formula being (C8H8)x·(C4H6)y·(C3H3N)z — is a high-impact thermoplastic resin based on a copolymer. ABS combines the strength of polybutadiene with the hardness and rigidity of polyacrylonitrile and polystyrene. ABS is a graft copolymer, that is, a giant molecule consisting mainly of polybutadiene chains growing from the backbone of a styrene-acrylonitrile copolymer.

It was invented during the Second World War and was used as an alternative to rubber. ABS was patented in 1948 and marketed by the BorgWarner corporation in 1954.

Source: wikipedia.org

In terms of chemical composition, ABS plastic is divided into two main groups: the most commonly used pure ABS and composite polymers (for example, ABS/PC, ABS/PVH, ABS/PBT, and the like), in which the properties of ABS are enhanced by other additives. ABS is widely used to make various household goods, industrial parts, and medical products.

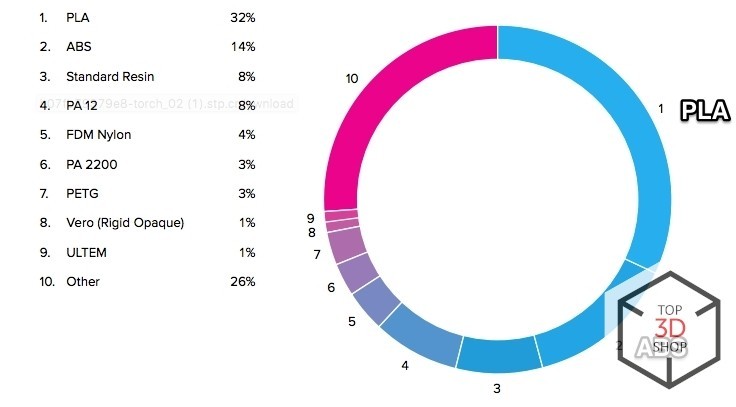

ABS is one of the most commonly used materials for extrusion 3D printing.

Source: stratasys.com

ABS is a yellowish opaque material (although there are transparent varieties). The main characteristics of ABS plastic are:

Parts made of ABS can be used in temperatures between -40°C and +90°C. ABS dissolves in acetone, esters, ketones, 1,2-dichloroethane, ethyl acetate. ABS parts can be mechanically processed. Products made of this plastic can be recycled. It is vulnerable to direct sunlight and ultraviolet radiation.

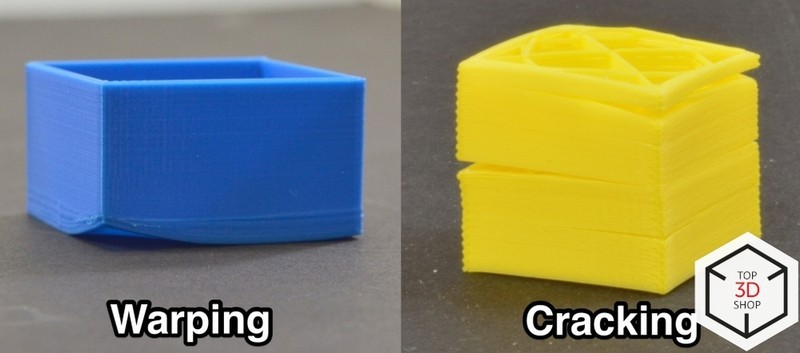

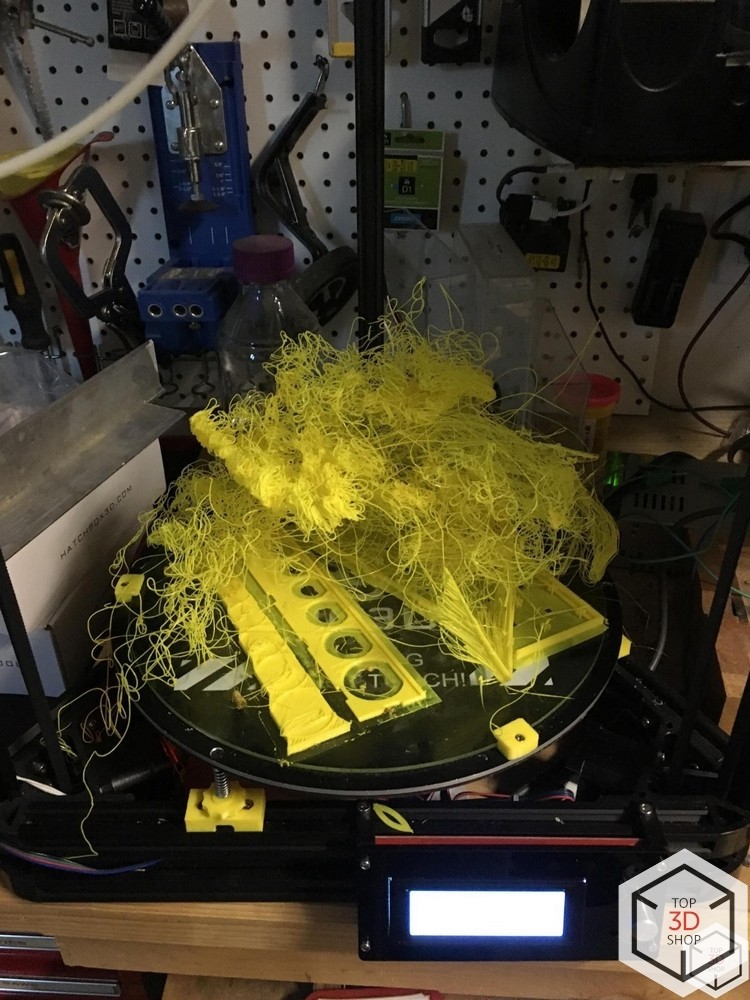

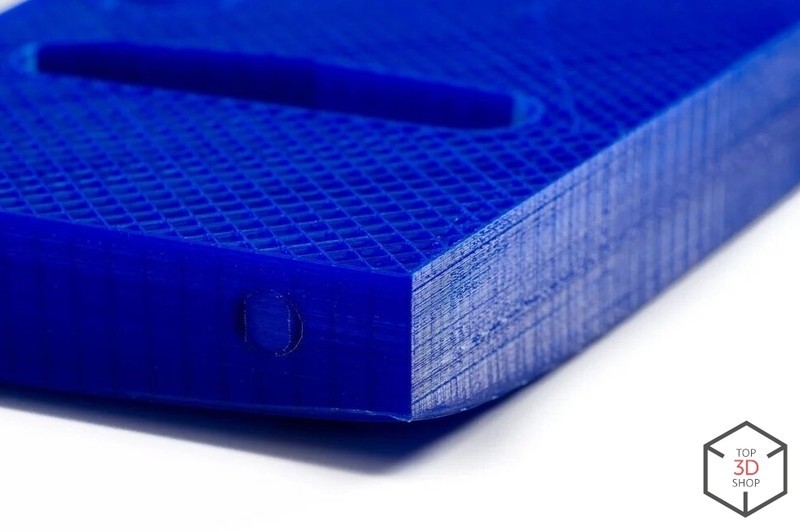

Source: bitfab.io, examples of printing flaws

Source: all3dp.com

ABS is a petroleum-based plastic that is not biodegradable. It is inherently more toxic than PLA. Although it does not emit toxic substances under normal conditions, the unpleasant odor of hot ABS speaks for itself: this material cannot be wholesome. The long-term effects of exposure to ABS vapors are not fully explored. A 2015 study found that “both gaseous molecules and nanoparticles released during 3D printing enter the human body through the skin and respiratory system. Ultrafine particles are deposited in the cells of the respiratory system and through the olfactory nerves of the nasal mucosa enter the brain. Vapors from melting plastic can irritate eyes, skin, and respiratory tract, and with prolonged exposure can cause nausea and headaches."

Although the vapor content of ABS plastic in 3D printing is negligible, it is recommended to operate a printer using this plastic in a well-ventilated area or using a fan. Besides, for post-processing, smoothing, or gluing, highly volatile, toxic, and flammable substances such as acetone are used, the handling of which requires strict adherence to safety measures.

Another safety issue is the need to maintain the temperature of the printed part on printers that do not have an enclosed chamber. Users often employ makeshift and extremely unsafe ways to prevent the printed product from cooling down, for example, covering the 3D printer with thermal insulating materials, which can lead to either damage to the device or a fire.

Source: all3dp.com

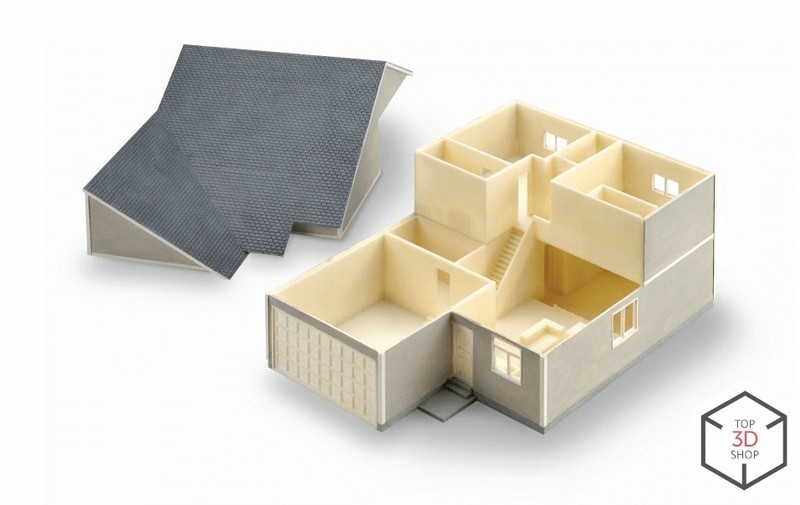

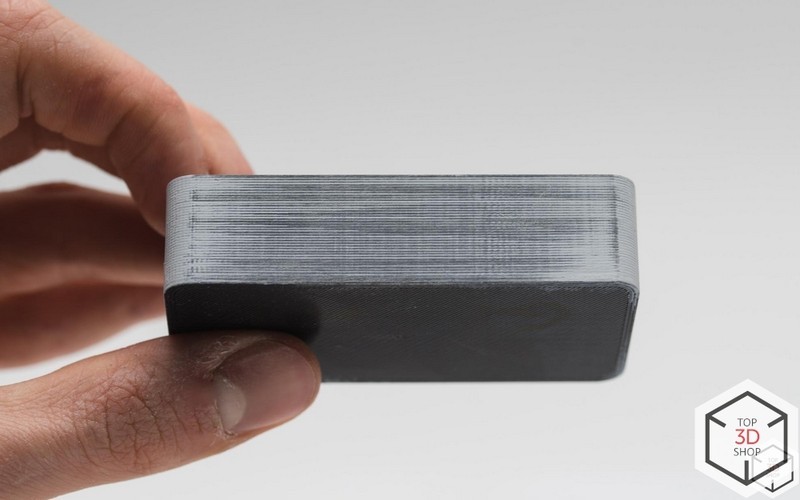

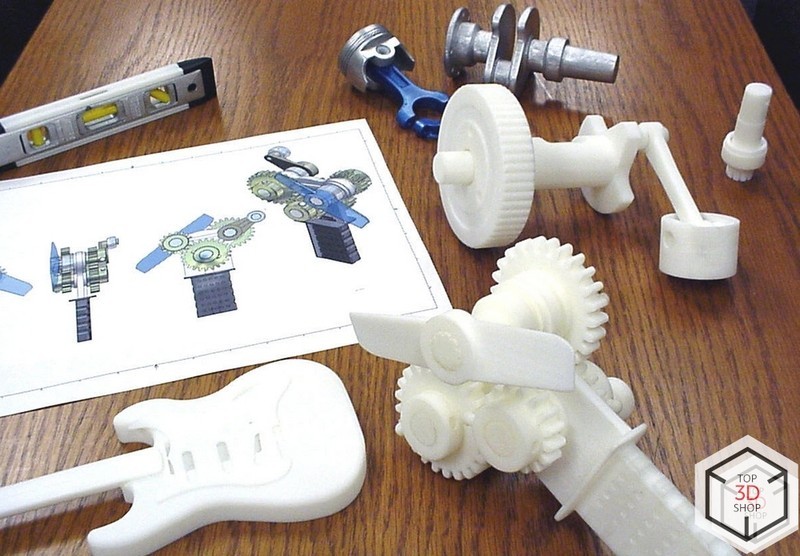

The reasons for the popularity of ABS are historical: this well-proven thermoplastic has long been used in the traditional manufacturing industry when the development of additive manufacturing began. Thus, it turned out to be one of the first polymers used for 3D printing. Despite all its shortcomings, it still remains one of the best materials for FDM/FFF printing with high detail or, if necessary, mechanical post-processing of parts. In terms of heat resistance, it is second only to nylon and much more expensive engineering polymers.

Source: bitfab.io

Source: wanhao3d.ru

Filaments based on ABS are hygroscopic, so they must be stored in hermetically sealed packaging. It is recommended to dry them in special devices before use, for example, Wanhao Boxman 2.

Source: gulfcoast-robotics.com

Heated plates should be used to ensure a good first layer adhesion and to avoid print defects such as delamination and detachment from the platform. The recommended platform temperature is from 90 °C.

Source: instructables.com

When printing on non-heated platforms, it is necessary to use either special adhesives or coat the platform with a suspension of ABS and acetone.

The speed and other parameters of 3D printing depend on many factors, for example, the presence of an enclosed print chamber, extruder temperature, nozzle diameter, and so on. The speed of printing ABS is a compromise between an increased print time and the absence of defects in the printed part. When setting the parameters, you should mind the recommendations of the printer manufacturer, filament properties, and user experience.

When 3D printing with ABS, the cooling of the extruder must be turned off.

Source: 3dhubs.com

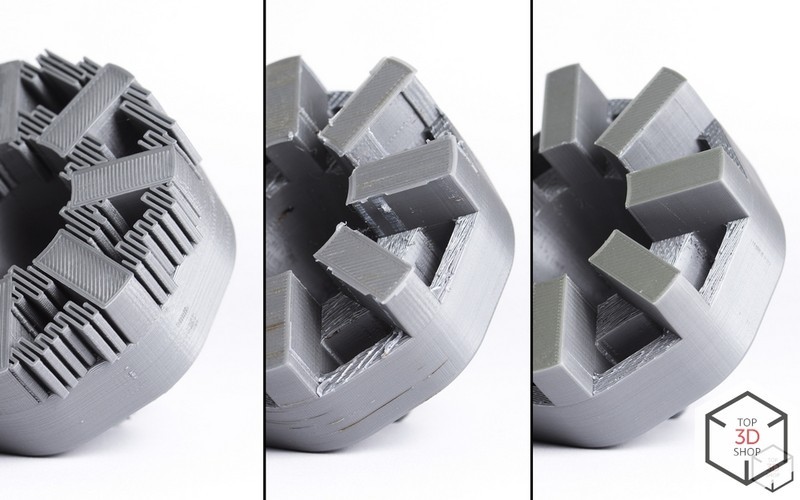

The manual post-processing of ABS is an expensive, long, and laborious process, making it difficult to use 3D printing in mass production. The post-processing costs can turn out nearly a third of that of producing a 3D model. According to Wohler's 2018 report, they can amount to 27% of the total cost, including the risk of a part failure.

Source: 3dhubs.com

When printing models with elements whose angle (depending on the brand of ABS used) exceeds 45–70°, it is necessary to use structures that support the overhanging elements. Such structures can be printed using the same plastic as the model itself, but when the machine is capable of printing with multiple filaments, special support materials can be used.

Source: airwolf3d.com, an example of printing with soluble supports

Insoluble materials are relatively strong and can be removed only with tools such as knives or wire cutters. This must be done carefully as there is a risk of damage to the model or accidental removal of small elements.

When using soluble materials, the risk of damage is lower. The support structures dissolve in water (PVA) or with special solvents that do not affect ABS, such as limonene (HIPS), isopropyl alcohol (isopropanol), or a 1:1 mixture of both. Limonene and isopropyl alcohol are rather toxic, so when working with them, it is important to follow the same precautions as when working with ABS itself. Printed products with water-soluble supports are not to be washed in a dishwasher.

Source: pinshape.com

One of the easiest and most effective ways to smooth ABS is by using acetone. Place paper towels on the bottom of a plastic or metal container to cover its entire inside. Pour a small amount of acetone onto the bottom of the container so that it is completely absorbed by the paper. Cover the bottom with foil (or make a "raft" from it) and place the part inside for a few hours. Tightly close the container with the lid.

After processing, carefully remove the product and leave it for a few minutes so that the acetone completely evaporates from its surface. When removing, try not to touch the part, taking it out along with the foil. Since the outer layer of the object will be half-dissolved, any touch will leave surface defects.

Avoid excessive exposure of the product to acetone vapor as this will reduce its strength. All operations must be carried out in a well-ventilated area and in compliance with fire safety rules.

Source: makerbot.com

Layer lines are clearly visible on products printed from ABS plastic using the FDM/FFF technology. Since ABS is easy to process mechanically, such lines can be removed with sandpaper of various grits and by polishing with special pastes. Care should be taken when sanding as small parts of the printed model might be accidentally removed. The applied effort should also be moderated so as not to damage the part. Be sure to use masks or respirators to protect yourself from dust.

Source: 3dhubs.com

If the size of the part exceeds the build volume of the printer, the 3D model is often divided into smaller pieces and reassembled after printing. ABS products can be “welded” with acetone. Mating surfaces must be cleaned of dust and dirt, moistened with acetone, and firmly held together until the acetone evaporates completely. Since an increase in the area of the parts to be glued increases the strength of joining, it is advisable to provide special places for joints in the composite 3D model. Acetone does not change the color of the part.

Be careful: excessive use of acetone can lead to the aggressive dissolution of the part and adversely affect the final result. When designing a model, keep in mind that the strength of the glued joint is lower than the strength of other areas of the printed part.

Source: 3dhubs.com

Voids in parts printed with ABS can be filled with a suspension of the filament and acetone that is chemically indistinguishable from the original material and will penetrate any voids on the surface. The recommended ratio is ⅓ of ABS to ⅔ of acetone, but if there is deep damage, the plastic content can be increased.

Also, an epoxy-based filler can be used for this purpose.

Source: makerbot.com

For ABS parts, use acrylic paints as they have the best adhesion to this plastic. When employing paint based on another compound, it is necessary to use acrylic primers. For the best surface finish, apply paint with a spray or airbrush. Be sure to test the paint adhesion to plastic on a test object before painting.

Source: makerbot.com

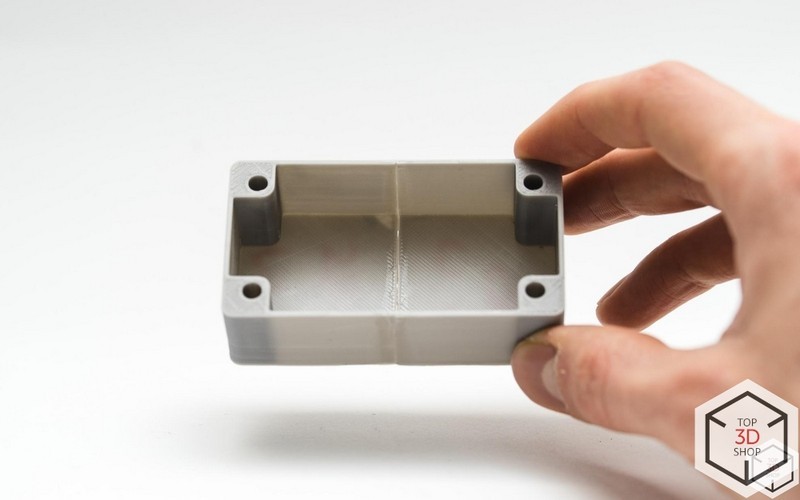

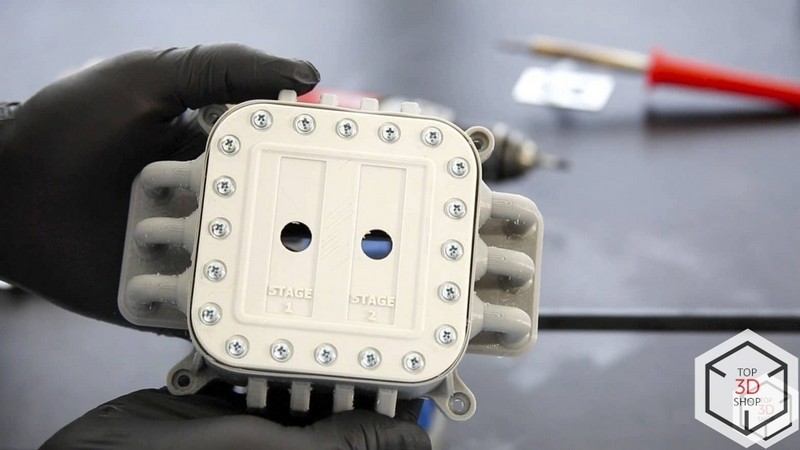

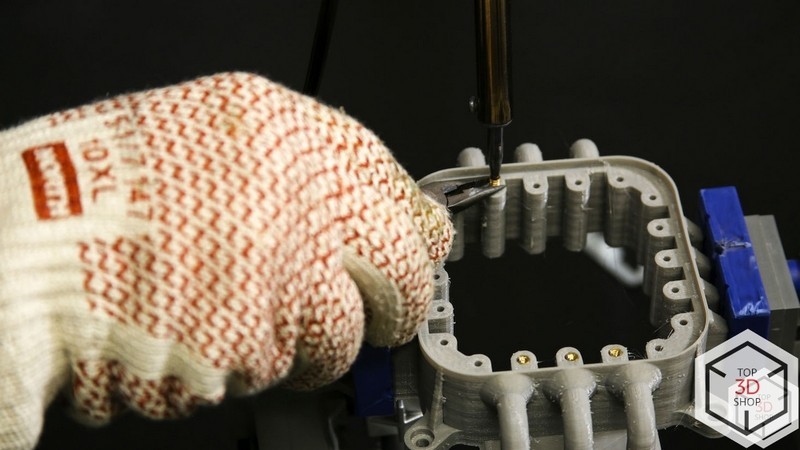

Threaded brass inserts are a good way to add durability to 3D printed parts that require a screw connection. When developing a 3D model, holes of a suitable diameter should be provided in the right places.

Source: makerbot.com

Place an insert halfway into the hole, then lightly press it vertically with a well-heated soldering iron. Wait until the insert is in the desired position and let the part cool down.

Source: all3dp.com

Recommended settings:

Source: all3dp.com

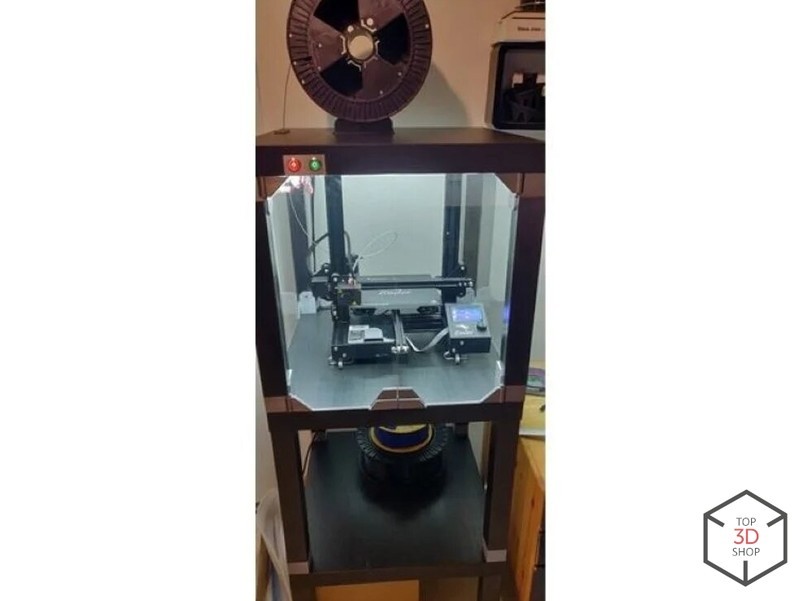

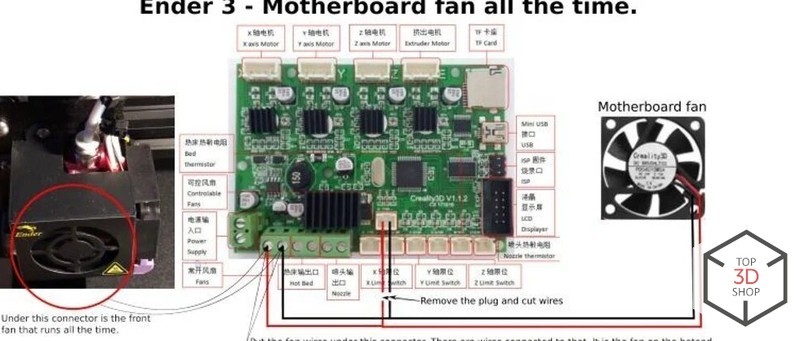

The feature of the Creality Ender 3 3D printer that makes the device difficult to use for ABS printing is that turning off the extruder cooler makes the motherboard fan turn off, too. To avoid overheating and failure of the electronics, it is necessary to modify the device in accordance with the given pattern.

Source: rckeith.co.uk

Recommended settings:

Source: rckeith.co.uk

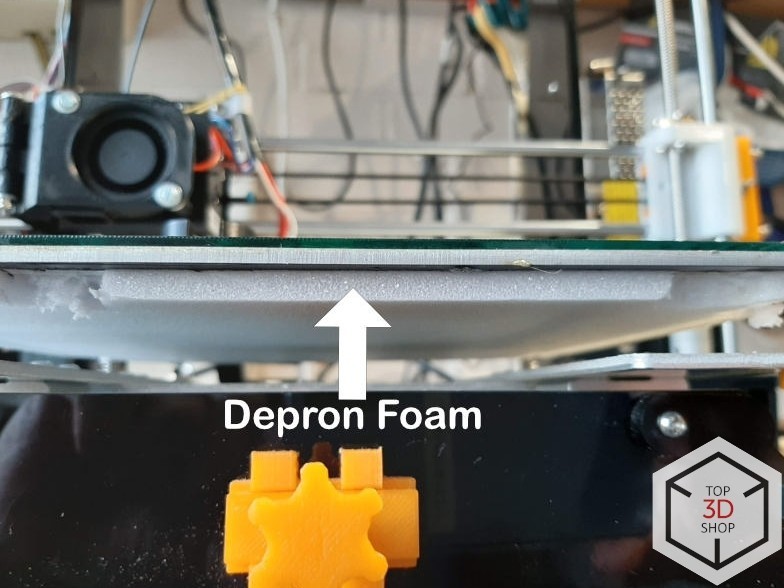

Before starting to print with ABS on this printer, users recommend sticking a thermal insulating pad on the bottom of the plate. Otherwise, the bed cannot reach the temperature over 90 °C required for good adhesion of the first layer.

In addition, it is recommended to either coat the platform with a suspension of ABS and acetone, or apply the special Kapton adhesive tape, or use the BuildTak film.

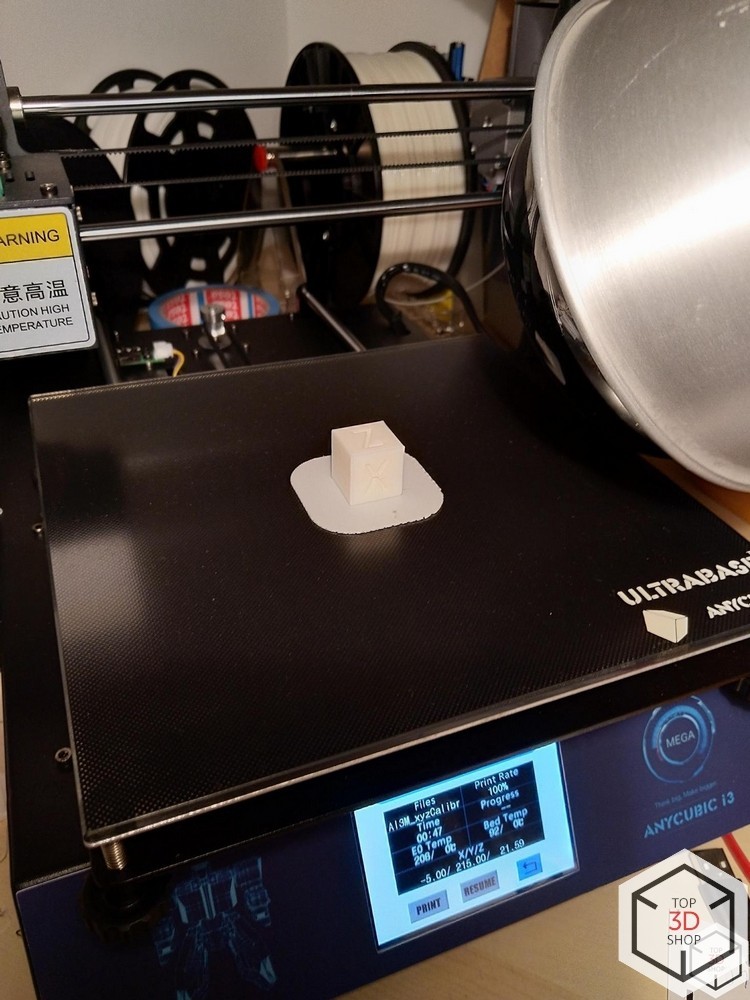

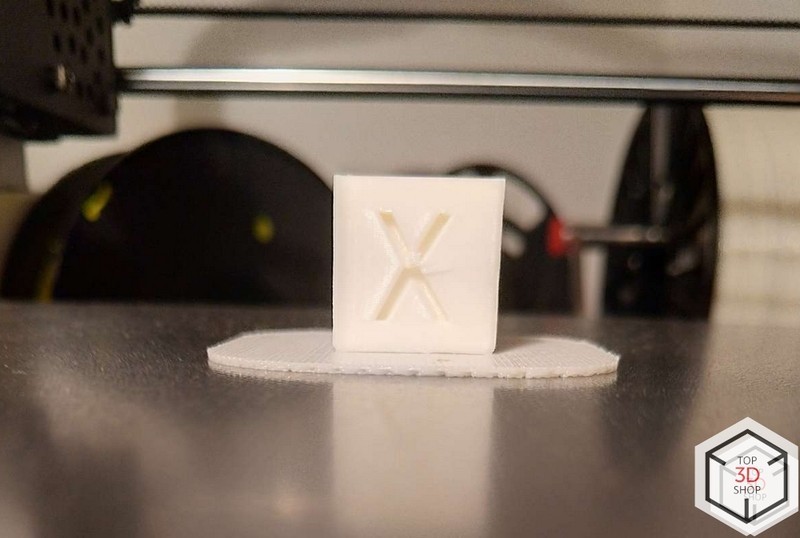

Source: ulrichpech.berlin

The print settings are the same as for the previous model. It is also recommended to coat the plate with a suspension of ABS and acetone, or apply a special adhesive or coating.

Source: reddit.com

People who work with 3D printers tend to strive for some ideal settings in order to print the best quality products. There are no fully definite settings for any material since the quality of 3D printing depends on many factors, such as the brand or design of a printer, the physical condition of filament and its manufacturer, the temperature settings of the printing platform, extruder, or chamber (if there is an enclosure). The awareness of the causes and solutions of the most common 3D printing problems is one of the core skills in the professional's arsenal.

Source: all3dp.com

Due to insufficient adhesion and uneven cooling of the plastic, sometimes the first layers stick off from the build plate, and the printed part warps. In this case, it is recommended to either increase the temperature of the platform (for heated beds), or coat the plate with a suspension of ABS and acetone, or apply the other adhesives mentioned above. Besides, when creating a model, it is desirable to increase the contact area of the part with the surface of the plate by including a raft in the project — an extended first layer.

Source: all3dp.com

The effect appears when molten plastic oozes out of the nozzle in places where the printer is not supposed to print. This occurs because the filament flows from the nozzle due to the pressure of the extruder but under the influence of gravity.

There are several reasons for such a defect and ways to solve them:

Source: all3dp.com

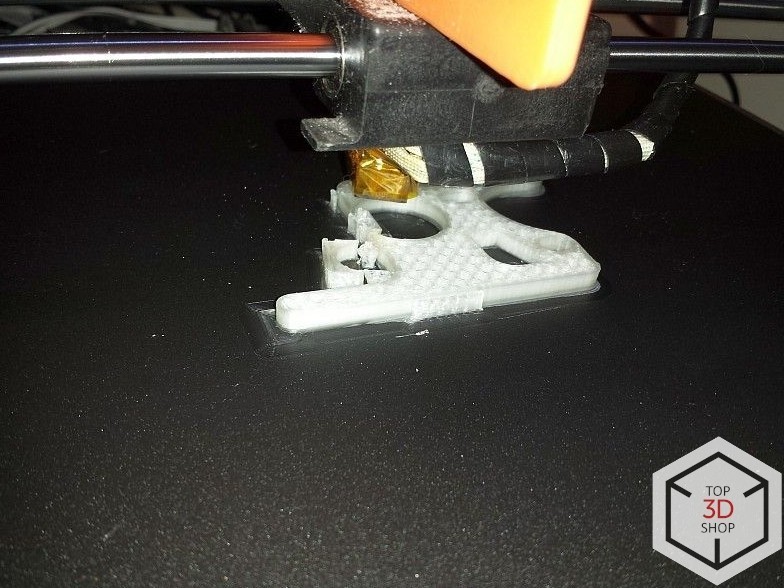

The lack of a closed chamber is always a problem when printing ABS — users have to resort to various ways to keep the temperature of the printed part. Otherwise, due to the temperature difference between the already printed layers and those being in progress, there occurs delamination of the part. ABS filament manufacturers recommend using enclosed 3D printers that can maintain high temperatures inside.

When using an open 3D printer, the following tricks can help prevent delamination:

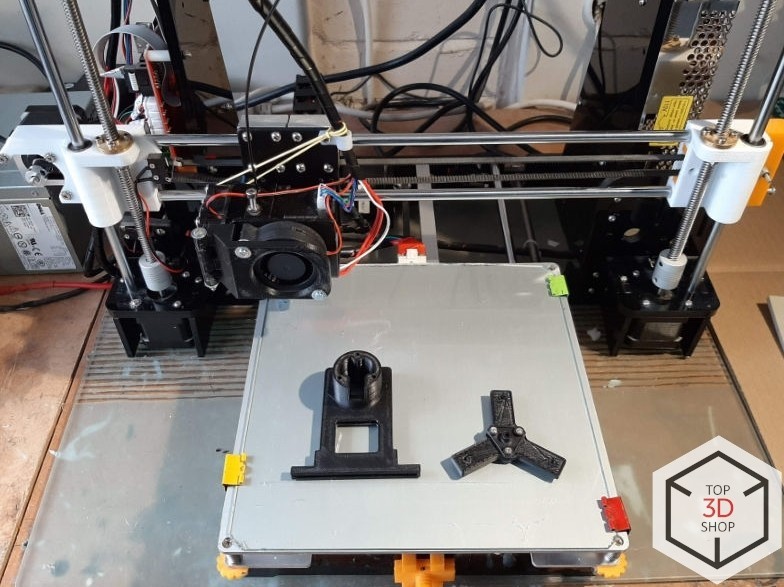

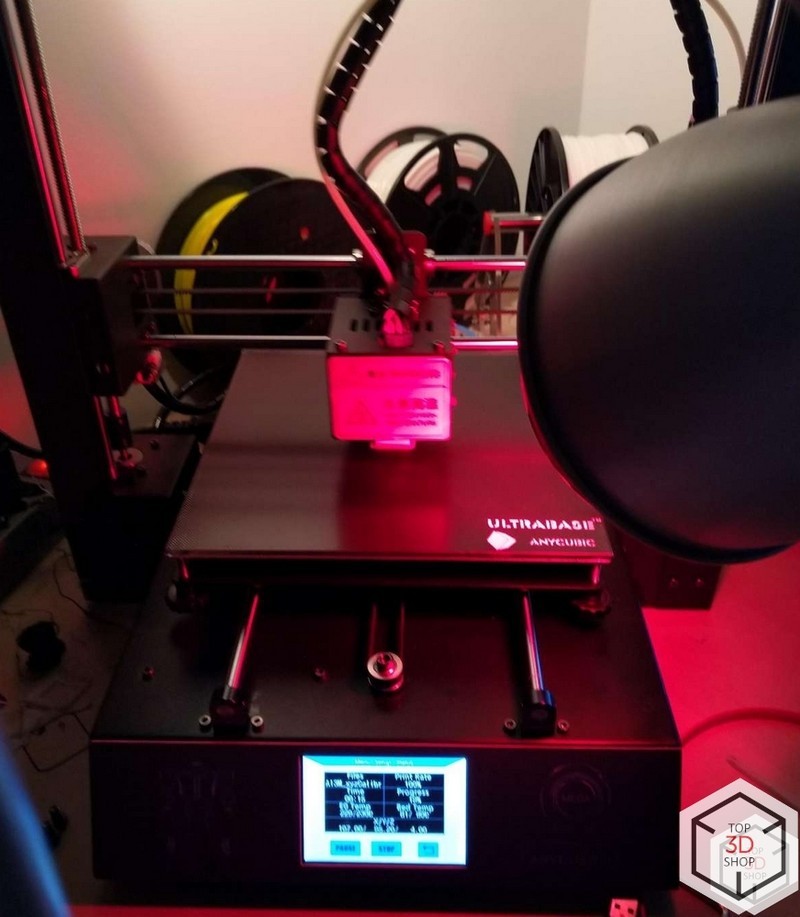

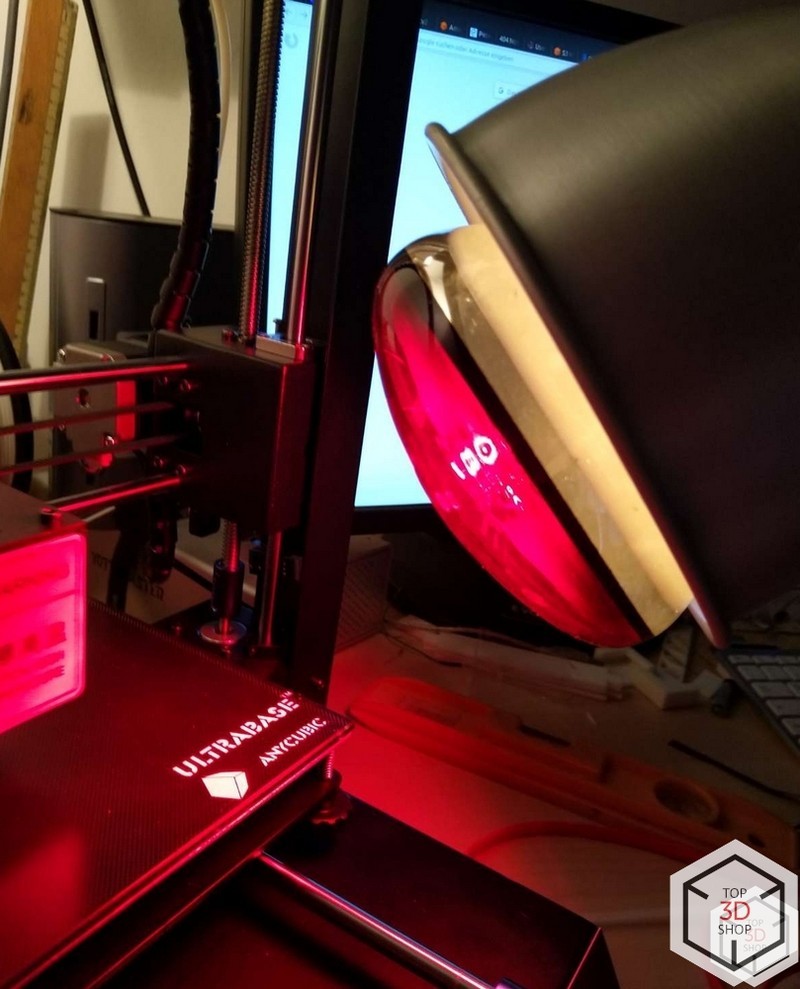

Ulrich Pech used an infrared lamp when 3D printing with ABS plastic on the Anycubic i3 Mega printer.

Source: ulrichpech.berlin

Ulrich says:

“The Anycubic i3 Mega is a good relatively low-cost 3D printer from China. It’s a very useful tool for DIY projects based on the open-source Prusa i3 made by Czech Josef Průša. It's a classic FDM printer with a 0.4 mm nozzle for the 1.75 mm extruder and comes with some nice features like touchscreen, filament sensor, SD-card reader, USB port for direct computer connection, spare hotend as well as an acrylic spool holder. The Anycubic Ultrabase heated bed makes the use of a glue stick or blue tape obsolete for this 3D printer. With this heated bed, the Mega is capable of printing PLA, PETG, HIPS, Wood, and ABS."

Source: ulrichpech.berlin

So, with its Ultrabase platform, the i3 Mega is indeed capable of printing ABS, but the problem is that ABS is sensitive to rapid cooling. As a result, parts warp and bend when printed.

Source: ulrichpech.berlin

Ulrich found an original yet simple solution to this problem:

“I use an old Nava infrared bulb with a floor lamp from Ikea. The infrared bulb has around 200W and keeps the 3D print warm on the Anycubic. The best result came out in combination with a raft created in the Cura slicer software. As temperatures, I used 90 °C for the bed and 230 °C for the extruder. With that, the print of the calibration cube was printed without any bending or warping."

Source: ulrichpech.berlin

“Be careful! If the printed object comes too close to the infrared lamp, e.g. after the 3D printer finished, it will melt the model in the head of the bulb,” Ulrich warns.

On the left of the picture is a product after acetone smoothing. Source: all3dp.com

Source: 3dinsider.com

Source: 3dprintingsolutions.com.au

Source: all3dp.com

Source: lpfrg.com

Source: quantum3dprinting.com

Source: 3dinsider.com

It is no wonder that ABS plastics have become one of the main 3D printing materials. While companies and enthusiasts continue to search for the best consumables for 3D printers, this popular polymer still ranks high on the general set of characteristics, including hardness, strength, gloss, and electrical insulation. ABS is also used to create composite filaments with different levels of flexibility or viscosity required to make a specific product or design.

Update your browser to view this website correctly. Update my browser now

Write a comment