PETG plastics (polyethylene terephthalate glycol) are strong polymers suitable for making a variety of objects, including utensils that come into contact with food not hotter than 75°C. PETG filaments are available in various colors. They are relatively easy to 3D print.

Read the article to learn about the capabilities and applications of PETG.

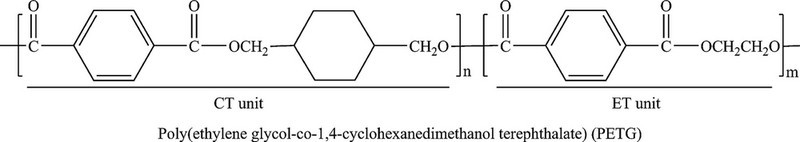

Source: pubs.rsc.org

PETG is a copolymer, a thermoplastic that is widely used for domestic purposes — for example, for creating food containers and sports flasks.

Source: banggood.com

PETG is formed by modifying the PET (polyethylene terephthalate) polymer chain with ethylene glycol molecules. This change in composition and structure imparts greater rigidity to the material.

Source: alibaba.com

PET, the predecessor to PETG, was developed simultaneously in several countries in the 1930–1940s. In Britain, a patent for polyethylene terephthalate was obtained in 1941. John Rex Whinfield and James Tennant Dickson, specialists of the textile company Calico Printers' Association, created a material that could be used to obtain synthetic fibers.

Subsequently, various corporations used their own names for the polymer, but in recent decades the chemical abbreviation PET has been commonly used, as is the case with copolymers formed on the basis of polyethylene terephthalate. Therefore, PETG, strictly speaking, is a special kind of PET, but it is customary to separate these materials because the properties of PETG and “pure” PET are different.

PETG plastic is a transparent colorless dielectric material. It is notable for its high strength and high melting point. A characteristic feature of PETG is its resistance to many chemicals and UV light. The abrasion resistance, in turn, is average. The surface of a product 3D printed with PETG can be as smooth as that of a plastic bottle, but this requires additional processing.

The main characteristics of the polymer are as follows:

PETG has durability and impact resistance superior to PET. The material demonstrates good chemical resistance to both acidic and alkaline substances. It also has excellent moisture-blocking properties, which makes it suitable for creating containers for water or other drinks.

In terms of ease of handling in 3D printing, PETG's excellent adhesion ensures minimal probability of deformation and delamination. PETG filament combines the best properties of PLA and ABS: it is strong and heat-resistant yet easy to work with.

A significant advantage of PETG filament is the absence of unpleasant odors during printing on account of the chemical release. However, it is recommended to print with the material in a well-ventilated area and wear a respirator.

Designers and engineers can print functional prototypes of containers for liquids, enclosures for electrical equipment, and more. The most obvious use for PETG is the design and prototyping of consumer packaging, which would later be mass-produced from PET or other polymers.

The chemical resistance of PETG along with its mechanical durability is an important advantage when creating strong non-standard parts such as production tools and auxiliaries, testing components, or robotic machines. PETG can be used for printing snap joints and movable hinges, protective covers, or custom machine parts.

PETG is hygroscopic, which means it will actively absorb moisture from the air. For this reason, the plastic should be stored in a cool dry place. If it happens to be exposed to humid air for too long, it should be dried. When the dryness of the material is unknown, the filament should be dried in a special device, for example, the Wanhao Boxman-2.

PETG can be used with enclosed and open 3D printers. The print bed should be heated to 75–90 °C. For adhesion of the first layer, the bed must be covered with a coat of glue or "printing juice" — a solvent with plastic dissolved in it. The extruder temperature is 230–250 °C. The retraction should be set at 25 mm/s.

The recommended speed for PETG 3D printing is 60 to 100 mm/s. Printing at a higher speed may adversely affect the result. To change the quality of a finished product, it is advisable to set the print speed at 30 to 60 mm/sec.

3D printing with PETG filament requires cooling: at the level of 20% cooler speed for the first layer and up to 100% for the rest of the object.

Since the polymer melts at high temperatures, the edges of the finished product can be polished with flame. If there are many thin threads left during the printing process (stringing effect), they can be removed as well.

The physical properties of PETG printed products allow for various machining of finished surfaces. You can drill holes in the body or polish the surface of parts, in which case polishing wheels or regular sandpaper is employed. The video example shows how the polishing process changes the appearance of a souvenir printed from PETG filament with added copper.

Painting finished products printed from PETG is tricky. The only obvious way is to use spray paint or a spray gun.

PETG parts can be securely bonded with cyanoacrylate. Alternatively, you can use a solvent.

Recommended settings:

For PETG printing, the Creality Ender-3 used the settings recommended by the filament manufacturer. An example of PETG printing on the Ender 3 showed that the material creates a quality product even with the relatively large print layer height.

Recommended settings:

This comparison test features two printers: the Creality Ender-3 and the Anycubic Chiron 3D. For the Anycubic 3D printer, which has a large build volume, several 3D models were chosen, including a large polygonal vase made of transparent filament. The print result is excellent, even without mechanical surface treatment.

Recommended settings:

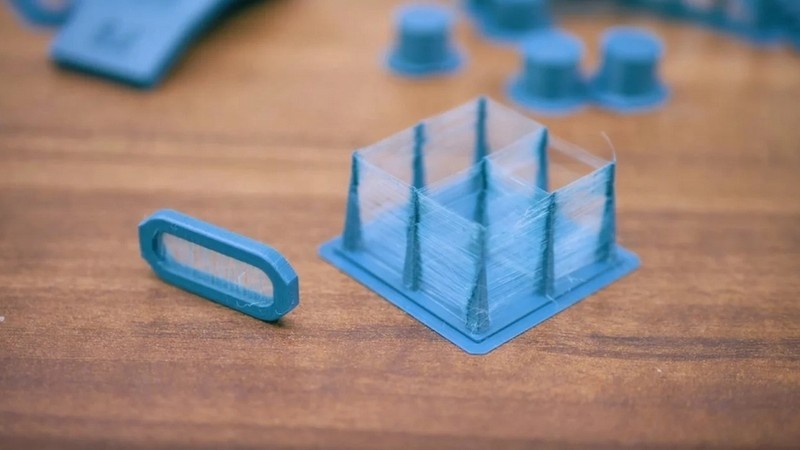

Anet A8 was used to print a small model with a complex shape and a lot of supports. The video shows how difficult it is to remove the support: in addition to working with nippers, significant sanding of the connection points of the supports and the part is required.

Source: all3dp.com

The two main mistakes to occur when printing with PETG filament are stringing and sagging.

To prevent stringing (the formation of redundant threads), you should:

To avoid the formation of sags at the border of the printed layer, you should also adjust the retraction settings towards higher values.

Source: prusament.com

Source: 3DSourced.com

Source: all3dp.com

Source: all3dp.com

PETG filaments have numerous advantages making them a convenient material for 3D printing. Products made of PETG are durable and resistant to many aggressive environments. The filaments are available in dozens of colors, transparent and opaque, including metallic. The process of printing with PETG is devoid of unpleasant odor. A finished product is easy to smooth and polish to create an elegant look.

Update your browser to view this website correctly. Update my browser now

Write a comment