You can end up in one of three situations that require using test models for 3D printing. First, when using a new printer. Second, when checking out a new type of material. Third, when testing the properties of a familiar type of material to find the limits of its strength. In this review, we will talk about the seven test models we find most useful or interesting.

Read the article below to learn more.

Source: help.prusa3d.com

3D Benchy is the most popular 3D printing test model. This tugboat figurine perfectly shows the abilities of FDM 3D printers of any price range. 3D Benchy will help you find the parameters that need to be set to get perfect prints.

Source: thingiverse.com

Using 3D Benchy for test printing allows you to see how good a printer will be at creating curved surfaces, inclined elements, arcs, and holes. The model is available in different versions, including a multi-color one. Printing standard-sized 3D Benchy will take approximately an hour — knowing this will help to determine the level of efficiency of a printer.

Download the model from Thingiverse.

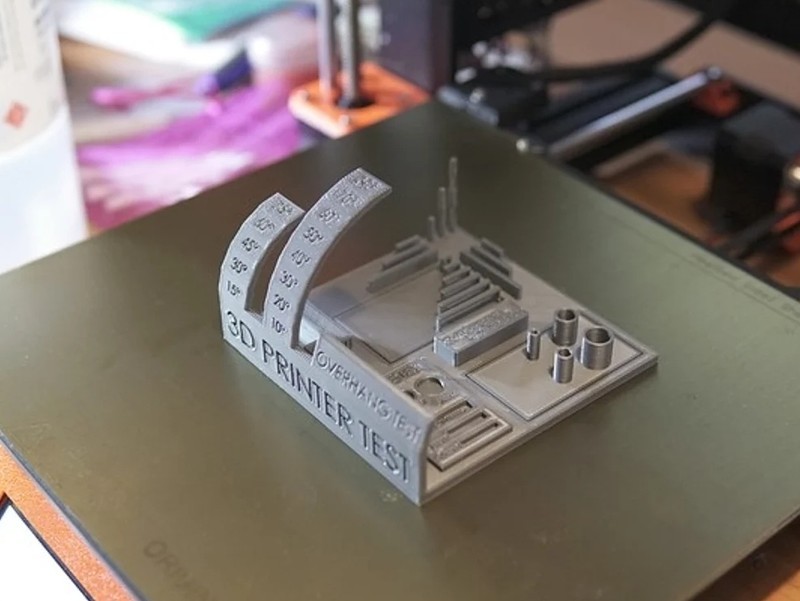

A complex 3D printing test model will allow checking the quality of resulting overhangs, bridges, as well as extrusion stability and changes of stringing (spaghettification) and it depends on temperature.

An important advantage of this model is an inclusion of an instruction that describes the ways to solve potential problems.

Source: thingiverse.com

The pros of this project include the ability to check how thin walls, hollow cylinders or overhangs will look, as well as how their quality will depend on speed, temperature and cooling settings.

Download the model from Thingiverse.

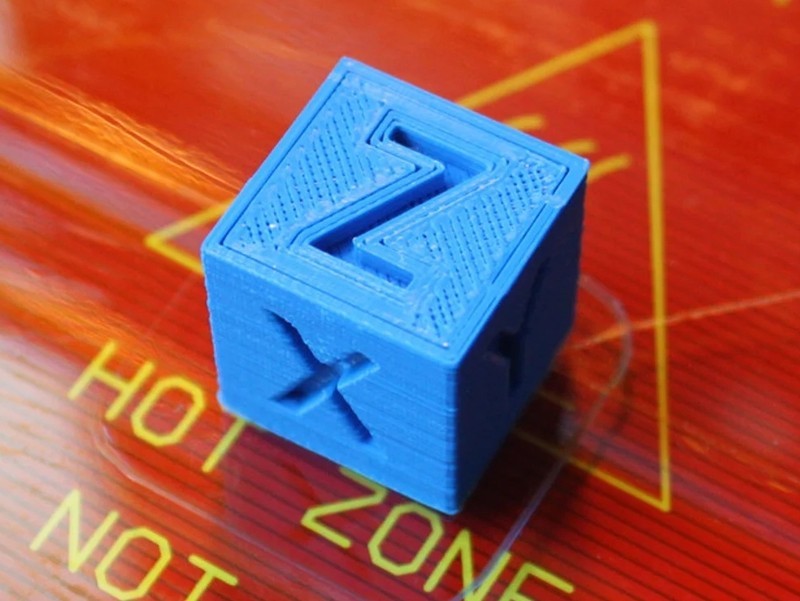

The main purpose of the XYZ 20 mm calibration cube is to find out how the extruder’s movement depends on the steps of a stepper motor. This 3d printing test model helps ensure that the distance of 20 mm on a drawing translates to 20 mm in a printed model. The calibration cube will also allow us to find out how extrusion and print quality depend on the nozzle temperature.

Source: thingiverse.com

Download the model from Thingiverse

This temperature calibration tower showcases a 3D printer’s abilities to utilize the same with different temperatures. The model demonstrates the quality of overhangs and tunnels, as well as how good the printer is at producing curved elements.

Source: thingiverse.com

This simple tool makes it easier to find the abilities of the materials that weren’t used before or were only printed at a certain temperature. It’s important to keep in mind that the printing temperature for each element must be set in slicing software or manually using G-code.

Download the model from Thingiverse

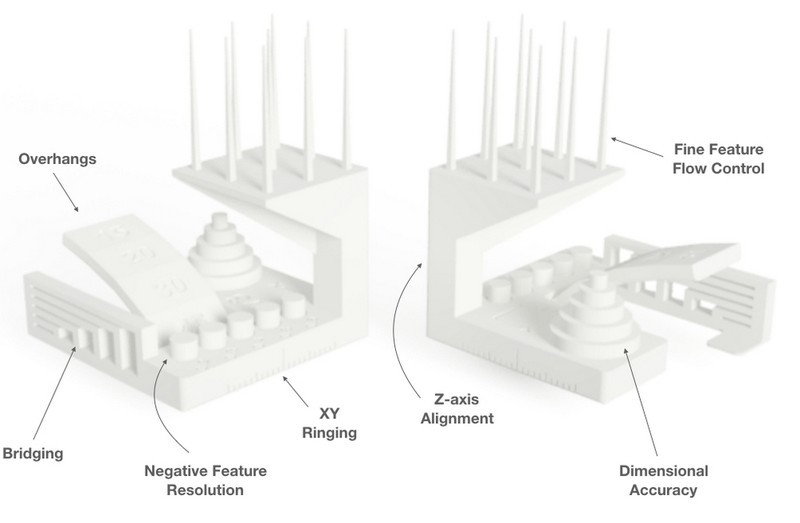

Source: github.com

3D printing test model by Kickstarter and Autodesk was developed with the consideration of the experience of using other testing models. This one can be considered multi-purpose. It includes bridges, overhangs, small details, and the elements to access the dimensional accuracy of 3D printing. Before printing one should keep in mind the size of an overhang at the upper level. This means that a user should know the temperature at which the model will not deform.

Download the model from Github

When printing complex models without knowing about the properties of a filament and a printer, one can encounter an issue called stringing or spaghettification: it’s when extruder motion stretches the filament, creating thin threads in the air.

Source: thingiverse.com

It is caused by a filament leakage when the extruder is inactive. Filament retraction function is used to avoid it. The correct retraction level should be based on extruder head movement speed, nozzle temperature, and filament properties.

This test model is used to quickly check if the printer is set up correctly. If there are no strings between vertical pyramids, then the parameters are set correctly. If the horizontal filament lines are present, then some parameters are set incorrectly and should be changed.

Download the model from Thingiverse

Another way to test printing parameters is the PolyPearl Tower. The features of this complex model allow one to check the quality of bridges, curves, overhangs, to see if there’s some stringing and find out how rigid the model is. The model can be used for stress-testing to find out the physical limits of a filament with a certain temperature and printing speed.

Source: thingiverse.com

Download the model from Thingiverse

3D printing test models can save the time and resources of a user. They don’t take longer than an hour to print, their quality shows whether the printing parameters were set correctly or need to be changed. Users can easily change the settings of a 3D printer if needed.

Buy a 3D printer and 3D printing materials at Top 3D Shop — and get officially distributed products with a warranty, service, and technical support.

Update your browser to view this website correctly. Update my browser now

Write a comment